Research Article

Volume 3 Issue 2 - 2018

Comparative Evaluation of Rumptstad 2- Wheel Tractor and Oxen Ploughing System: A Case Study in Northwest Ethiopia

1Bahir Dar University, College of Agriculture and Environmental Sciences, Bahir Dar, Ethiopia

2Department of engineering, Bahirdar Polytechnique institute, Bahir Dar, Ethiopia

2Department of engineering, Bahirdar Polytechnique institute, Bahir Dar, Ethiopia

*Corresponding Author: Astewel Takele, Bahir Dar University, College of Agriculture and Environmental Sciences, Bahir Dar, Ethiopia.

Received: October 05, 2018; Published: November 28, 2018

Abstract

This experiment was intended to evaluate tillage cultivation of maize and rice production using Rumptstad two-wheel tractors over farmers' oxen plowing in the rain fed production system. For this study, a total of 21 households was selected and field trials were conducted. For the trials, Rumptstad practice and Farmers' practice were considered. For the study, economic viability was evaluated using break-even point analysis (BEP) and partial budget analysis were adopted to evaluate the profitability of the two treatments. The study results showed that the theoretical field capacity for 2WT 0.213ha/hr, the average actual field capacity 0.060ha/hour and its overall average efficiency 40%. The BEP of oxen owned and oxen hired was about 4.5 hectares for less than 4.5 hectares of land, it is cheaper to rent-in to pay than owning an ox. Similarly, the BEP of oxen owning and tractor hiring is 4 hectares of land that means tractor hiring is profitable if a farmer's land holding is greater than 4 hectares of land, but at any case tractor owning is not a profitable business under the current condition of the farmers. The partial budget analysis indicated that using Ramptstand has a change in net income to the farmers by 1,509 Ethiopian Birr ($69 dollar) over an oxen ploughing system in the study area. Therefore, popularizing and promoting tractor service may increase farmers’ income.

Keywords: Rumptstad -2WT; Tractor hiring service; Partial budget; Break –even point

Background

Agricultural mechanization is integral to the agricultural transformation in most developed nations. Tractor use on the farm when properly applied can improve overall efficiency, maximize both land and labour productivity and lead to increase economic returns to the farmer (Celerina and Maranan, 1982). One of the main causes for the low agricultural productivity in most developing countries is the lack of appropriate machineries that cater to and suit the requirements of small-scale farms (Faleye., et al. 2012).

Agriculture is a means of livelihood for about 85% of the Ethiopian population, and yet the sector unable to feed its population. Most Ethiopian farmers still rely on manual labor or draught animals for farming activities and tractor use is limited to some smaller companies. There are many challenges in its suitability to small farms; simple design and technology; use in different farm operations; affordability in terms of cost, the provision of support services from the government and the private sectors/manufacturers and lack of financial support (Faleye., et al. 2012) besides, farmers experience, oxen ownership, property of soil in the area (Astewel and Yihenew, 2018) and natural hazards like climate change are some noted reasons.

For the last 3000 years, Ethiopia used traditional implements for farming (maresha plough) and animal power (oxen) However, the ox ploughing system is currently under stress because of shrinking cultivated areas per household, reduced fodder availability and land degradation (Aune., et al. 2001). Moreover, the maresha ploughing system exposes the soil to erosion and can be expensive for farmers without oxen. In most cases animal traction reduces the timeliness of farm operations (drudgery) and limits the efficacy of essential operations such as cultivation and weeding, thereby reducing crop yields (FAO and UNIDO, 2008).

Studies indicated that an increasing number of farmers are not able to maintain a pair of oxen. About 29% of Ethiopian farmers have no oxen, 34% have one, 29% have two and 8% have two or more. Hence, more than 60% of the farmers have to rent or borrow one or two animals for cultivation (Melaku, 2011).

Small farmers who rely on oxen of others for land preparation cannot plough at the right time (due to short preparation time at the onset of the rainy season) and pay between one quarter and half of their output of cereals and pulses for hiring a team of oxen. Access to oxen can be seen to be more important than land size in the Ethiopian context, because without the oxen, the land cannot be cultivated. It is also more difficult for farmers without oxen to intensify production, as a part of the surplus is reserved for the oxen owner (Aune., et al. 2001).

Understanding the characteristics of tractor service is therefore essential in designing an appropriate agricultural mechanization policy. This study would help to explore the options of integrating animal power with motorized technology (tractor) in the future. As part of the farm activity, this study was conducted with the objectives of evaluation of 2-wheel tractor utilization and oxen ploughing on production of crops in the northern part of Ethiopia.

Research Methodology

The study area

The study area is located in two woredas depending upon the crop type. Mecha and South Achefer woreda for maize production and Dera woreda for rice production. Both were selected purposively and it is a potential area for these two crops. Moreover, irrigation production is common in this area during dry seasons.

The study area is located in two woredas depending upon the crop type. Mecha and South Achefer woreda for maize production and Dera woreda for rice production. Both were selected purposively and it is a potential area for these two crops. Moreover, irrigation production is common in this area during dry seasons.

Mecha woreda: Mecha is also one of the thirteen Woredas found in West Gojam Administrative Zone, located 30 km south-west of Bahir Dar town, the capital of Amhara Region. Tagele wedefit kebele (study area)is located at about 10 km away from Merawi town in the north direction. The total area of the Kebele is about 2, 860 ha. Of these, 1920 ha is used as crop land, 16 ha for grazing land and 26 ha of forest land. The Kebele has a total population of 9,400 and the total household is about 1558 of which 1366 are male headed and 102 are female headed households. The color of the soil is 96% red soil, 2% clay and 2% black soil. The climate is woina dega (moderate temperature) and the temperature on an average ranges from 180C to 230C (WARO, 2014).

South Achefer woreda: Maize trial was located at Mecha Woreda at Tagel wodefit Kebele. It is about 47 km away from Bahir Dar, the capital of Amhara Region, in southwestern direction. Mecha woreda is known for its flat topography which accounts about 75 percent of the total area of the woreda. The altitude of the woreda ranges from 1800 to 2500 meters above sea level and receives mean annual rainfall in the range of 1000mm to 2000mm. The village selected as a research site for this experiment, was Ahuri keltafa kebele.

Dera Woreda: The woreda is known for rice production and located in the south Gonder zone. The altitude of the Woreda ranges from 1,500 m to 2,600 m above sea level while the annual average rainfall is 1,250 mm. Jigna kebele is the area where the tractor trial was located and the topography of the Kebele is 100% plain. Crop production and animal husbandry are practiced and supplemental irrigation during dry season is a common practice in the area.

Description of the technology

- RUMPTSTAND two wheel tractor is a multi-purpose plowing machine and it works like farmers’ ploughing practice with a hand hoe which could make it successful in African markets (Figure 1a). The small size of the tractor and the possibility of making many of its parts locally makes it easily accessible by private investors, small holder farmers or cooperatives in Ethiopia.

- Oxen plowing: This is a locally available technology which is made of metal ploughing end called Marasha (Figure 1b). An ox ploughing in Ethiopia is common practice and was started 3000 years ago in the highland parts of Ethiopia.

Sample Size (Trial Farmer)

From three woreda twenty two participant farmers were selected by considering wealth-class, gender, crop type and soil type. These farmers were selected in collaboration with village level development agents based on their willingness to use technology and to cooperate in the trial. Among the twenty one participant farmers, sixteen were male and five were females. From these farmers, seven participated in the rice study (Dera woreda) and 15 farmers participated in the maize study at South Achefer and Mecha woredas. For the trial Nitisol and Vertisol soil types were used for the experiment, i.e. the rice was planted in Vertisols and maize on Nitisols. For the study, both qualitative and qualitative data were collected using structured questionnaire and experiment recorded sheets.

From three woreda twenty two participant farmers were selected by considering wealth-class, gender, crop type and soil type. These farmers were selected in collaboration with village level development agents based on their willingness to use technology and to cooperate in the trial. Among the twenty one participant farmers, sixteen were male and five were females. From these farmers, seven participated in the rice study (Dera woreda) and 15 farmers participated in the maize study at South Achefer and Mecha woredas. For the trial Nitisol and Vertisol soil types were used for the experiment, i.e. the rice was planted in Vertisols and maize on Nitisols. For the study, both qualitative and qualitative data were collected using structured questionnaire and experiment recorded sheets.

Data Analysis

The annual tractor use required for economic viability was evaluated using break-even point analysis. According to Paman., et al. (2010), the break-even area was calculated by dividing the fixed costs per annum by differences between the service charge and the variable costs.

The annual tractor use required for economic viability was evaluated using break-even point analysis. According to Paman., et al. (2010), the break-even area was calculated by dividing the fixed costs per annum by differences between the service charge and the variable costs.

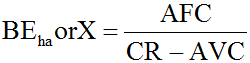

Breakeven analysis (BEA): is the level of operation at which an investment incurs neither a loss nor produce a profit. The annual fixed cost of ownership is assumed to be constant for the season or the year. Therefore, these costs become the key to calculate the breakeven point or the number of acres where the two alternatives are equally cost. The breakeven analysis for both practice (tractor and maresha) is carried out using the following formula (Muhammad, 1991; Pflucger, 1994, Heney, 2009)

CR(X) = AFC+AVC(X) (1)

CR (X)-AVC(X) =AFC (2)

X (CR-AVC) =AFC (3)

CR (X)-AVC(X) =AFC (2)

X (CR-AVC) =AFC (3)

Where

X= breakeven hectare; i.e., the required hectares needed to cover the total annual cost of tractor use

CR= custom or contract rate in Birr/ha

AFC= average fixed cost per year is the sum of depreciation (D) and interest on capital

Investment (i)

AVC= average variable cost in Birr per hectare

X= breakeven hectare; i.e., the required hectares needed to cover the total annual cost of tractor use

CR= custom or contract rate in Birr/ha

AFC= average fixed cost per year is the sum of depreciation (D) and interest on capital

Investment (i)

AVC= average variable cost in Birr per hectare

Cost Analysis

Types of cost items

a) Fixed and variable costs: In this analysis, tractor costs are divided into two major categories fixed and variable costs. Fixed costs include depreciation and interest on capital investment (the straight line method used for calculation of depreciation; the variable costs considered of fuel, oil, driver and repair and maintenance costs).

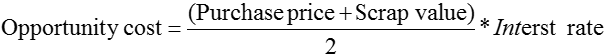

b) Opportunity cost (Interest on investment): The formula for calculating opportunity cost (average annual investment) is given by

b) Opportunity cost (Interest on investment): The formula for calculating opportunity cost (average annual investment) is given by

In the study area the lending institution in the area is Amhara Credit and Saving Institution (ACSI) and the interest rate for lending by ACSI considered was 17%.

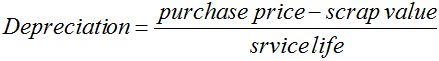

c) Depreciation: refers to the financial estimate of the annual loss of value of capital equipment due to wear and tear over its useful life. In this study straight line method of depreciation is used. The formula for the annual depreciation is

Terminologies and Assumptions

- Capital investment is the market price of RUMPTSTAD 2-wheel tractor and oxen plough considered for this analysis.

- Scrap/salvage value of the tractor: Salvage value is the remaining value of an asset after its economic life. It was calculated based on others researchers’ work and standardized estimates. Since RUMPTSTAD 2WT is introduced to Ethiopia in recent times and no remaining value cost data is established before. But by considering trends in other machineries salvage value the remaining value is assumed to be 20% of the initial purchase price in the depreciation period of the tractor.

- Service life for tractor: Service life is the period over which the equipment can operate at an acceptable operating cost and productivity. According to Celerina and Maranan, (1983), standard, the economic life of 2-wheel tractor is estimated to be 8 years.

- Fuel and oil consumption: The cost of fuel was 20 ETB/Lt and the average fuel consumption was about 2 liters per hour. It is recommended that oil and grease = 0.10 × fuel cost, but for this analysis, 15% of oil and filters were used.

- Repair and maintenance costs. The cost of tractor repair and maintenance depends on the frequency of tractor breakdowns. Data from the trial indicates that the most frequent breakdowns were due to problem of belts and handle this might be from frequent stopping and starting under plowing. The two wheel tractor is only used for plowing purpose in this case no other ploughing activities like seeding and line marking. For this analysis, 5% of purchasing price used.

- Tax: many researchers used and calculated as 0.30% of purchase price and insurance 0.20% of the purchase price. For this trial analysis we did not consider tax and insurance (as it is at instant time).

- Partial budgeting: The first step in doing an economic analysis of on-farm experiments is to calculate the costs that vary for each treatment. Costs that vary are the costs (per hectare) of purchasing inputs, labor, and machinery that vary between experimental treatments. Farmers will want to evaluate all the changes that are involved in adopting a new practice. It is, therefore, important to take into consideration all inputs that are affected in any way by changing from one treatment to another (CIMMYT, 1988). However, in our trial on a field scale, all inputs assumed constant (like seed, fertilizer and other activities) except the treatments (use of tractor and use of oxen ploughing).

- Opportunity cost: Not all costs in a partial budget are opportunity costs. Opportunity costs necessarily represent the exchange of cash. The opportunity cost can be defined as the value of any resource in its best alternative use. In the case of labor, for instance, farmers may do the work themselves, rather than hire others to do it.

- Total cost that varies. Once the variable inputs have been identified, their field prices determined, and the field costs calculated, the total costs that vary for each treatment can be total costs that vary calculated. The total costs that vary are the sum of the costs that vary for a particular treatment.

Results and Discussion

Socio-economic Information

A total of twenty one farmers participated and the majority of them are male headed farmers and few of them are female headed, selected based on the criteria of the experiment. As shown in Table 1, the majority were male and the rest female households. The educational status of the sample farmers poor, among them 33 percent were found to be illiterate followed by of grade 4 completed household’s head.

A total of twenty one farmers participated and the majority of them are male headed farmers and few of them are female headed, selected based on the criteria of the experiment. As shown in Table 1, the majority were male and the rest female households. The educational status of the sample farmers poor, among them 33 percent were found to be illiterate followed by of grade 4 completed household’s head.

| Variables | Frequency | Percent (%) | |

| Sex of households | Male | 16 | 76 |

| Female | 5 | 24 | |

| Total | 21 | 100 | |

| Model farmer or not | Yes | 12 | 57 |

| No | 9 | 43 | |

| Total | 21 | 100 | |

| Wealth status | Poor | 12 | 57 |

| Rich | 8 | 38 | |

| Medium | 1 | 5 | |

| Total | 21 | 100 | |

| Extension service | Yes/no | 21 | 100 |

| Access to market | Yes | 19 | 90 |

| No | 2 | 10 | |

| Total | 21 | 100 | |

| Educational status | Illiterate | 7 | 33 |

| Adult and religious education | 2 | 10 | |

| Grade 1-5 completed | 8 | 38 | |

| Grade 7-10 completed | 3 | 14 | |

| Grade 12 completed (10+2) | 1 | 5 | |

| Total | 21 | 100 | |

Table 1: Socioeconomic Characteristics of household head.

The total land size of the trial farmers is on average about 2.5 timad or 0.5 hectares and the average family size is about 2.32 per household (Table 2). The tropical livestock unit is about 5.56. The study indicates that the average distance that the farmers travel to the market is about 2 hours on foot.

| Descriptive Statistics | No | Minimum | Maximum | Mean |

| Total family members (no) | 19 | 1.00 | 4.00 | 2.32 |

| Total land size owned by the household in Timad (1/4ha) | 21 | 0.13 | 2.50 | 1.06 |

| Distance from the main market in (hours) | 19 | 0.50 | 2.00 | 1.26 |

| Total tropical livestock unit (TLU) | 18 | 2.07 | 10.63 | 5.55 |

Table 2: Land hold and oxen ownership of households.

Ploughing Capacities of RUMPSTAD 2WT

Field capacity of RUMPTSTAD 2WT

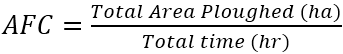

Field capacity is one of the performance measures of tillage implements (Bukhari., et al. 1988). In the experiment the field capacity of RUMPTSTAD 2WT was assessed. The field capacity of a farm machine is the rate at which it performs its function. Measurements or estimates of field capacities of a tractor are used to schedule field operations and to estimate operating costs. The most common measure of field capacity for tillage implement is expressed in the area ploughed per unit time of operation.

Field capacity of RUMPTSTAD 2WT

Field capacity is one of the performance measures of tillage implements (Bukhari., et al. 1988). In the experiment the field capacity of RUMPTSTAD 2WT was assessed. The field capacity of a farm machine is the rate at which it performs its function. Measurements or estimates of field capacities of a tractor are used to schedule field operations and to estimate operating costs. The most common measure of field capacity for tillage implement is expressed in the area ploughed per unit time of operation.

The actual/effective field capacity of RUMPTSTAD 2WT and its efficiency is calculated based on the following formula and summaries on the table below (Table 3).

| Wereda | Area Ploughed | Time Taken (hr) | Fuel Consumed (lt) | Fuel Cost | Fuel cost /ha | Fuel consumption (lt/hr) | Fuel consumption (lt/ha) | Ploughing capacity (ha/hr) |

| (M2) | ||||||||

| Dera worda | 875 | 1.6 | 1.8 | 28.98 | 331.2 | 1.13 | 20.57 | 0.05 |

| Dera worda | 667 | 1.4 | 1.75 | 28.18 | 422.41 | 1.25 | 26.24 | 0.05 |

| Dera worda | 627 | 1.2 | 1.6 | 25.76 | 410.85 | 1.33 | 25.52 | 0.05 |

| Dera worda | 1089 | 1.3 | 1.7 | 27.37 | 251.33 | 1.31 | 15.61 | 0.08 |

| Dera worda | 1018 | 1.3 | 1.5 | 24.15 | 237.23 | 1.15 | 14.73 | 0.08 |

| Dera worda | 1140 | 1.8 | 2 | 32.2 | 282.46 | 1.11 | 17.54 | 0.06 |

| Dera worda | 814 | 1.65 | 1.65 | 26.57 | 326.35 | 1 | 20.27 | 0.05 |

| South Achefer | 700 | 1.5 | 2 | 32.2 | 460 | 1.33 | 28.57 | 0.05 |

| South Achefer | 1110 | 1.8 | 2.2 | 35.42 | 319.1 | 1.22 | 19.82 | 0.06 |

| South Achefer | 1250 | 1.8 | 2.1 | 33.81 | 270.48 | 1.17 | 16.8 | 0.07 |

| South Achefer | 625 | 1.3 | 2 | 32.2 | 515.2 | 1.54 | 32 | 0.05 |

| South Achefer | 625 | 1.16 | 2 | 32.2 | 515.2 | 1.72 | 32 | 0.05 |

| South Achefer | 750 | 1.4 | 1.6 | 25.76 | 343.47 | 1.14 | 21.33 | 0.05 |

| Mecha woreda | 637 | 1 | 1.5 | 24.15 | 379.12 | 1.5 | 23.55 | 0.06 |

| Mecha woreda | 1008 | 1.67 | 2.5 | 40.25 | 399.31 | 1.5 | 24.8 | 0.06 |

| Mecha woreda | 608 | 1.08 | 1.5 | 24.15 | 397.2 | 1.39 | 24.67 | 0.06 |

| Mecha woreda | 750 | 1.4 | 2 | 32.2 | 429.33 | 1.43 | 26.67 | 0.05 |

| Mecha woreda | 1010 | 1.5 | 2 | 32.2 | 318.81 | 1.33 | 19.8 | 0.07 |

| Mecha woreda | 1250 | 2 | 2 | 32.2 | 257.6 | 1 | 16 | 0.06 |

| Mecha woreda | 810 | 1.2 | 1.6 | 25.76 | 318.02 | 1.33 | 19.75 | 0.07 |

| Mecha woreda | 1008 | 1.58 | 1.9 | 30.59 | 303.47 | 1.2 | 18.85 | 0.06 |

Table 3: Ploughing capacity of RUMPTSTAD 2WT for (rice and maize).

Note: trial crops; Dera Woreda for rice, Mecha & South Achefer woreda for Maize crops

Note: trial crops; Dera Woreda for rice, Mecha & South Achefer woreda for Maize crops

i. Theoretical field capacity (TFC) (ha\hr)

TFC=0.36 X working speed (m/sec) X working width (m) (7)

ii. Actual field capacity (AFC) (ha/hr)

iii. Field efficiency (FE) (%). Field efficiency was calculated by dividing actual field capacity of the tractor by theoretical field capacity of the tractor and multiplied by 100; hence, the theoretical field capacity is found to be 0.213ha/hour.

Accordingly, the minimum and maximum actual field capacities for maize cultivation (primary tillage) were 0.047ha/hour and 0.084ha/hour. Similarly, the minimum and the maximum actual field capacity for rice cultivation was 0.048 ha/hour and 0.068 ha/hour respectively. The average actual field capacity for all found to be 0.060ha/hour and it’s aver all average efficiency was 4.5% (Table 3).

Ploughing Frequency

The optimal land preparation condition for both RAMPTSTUD and control (Rice) practice was determined by the host farmers. Hence, the ploughing frequency was variable between fields. For the rice treatment, the ploughing frequency of rice ranges between 2 and 5. The mean was 3.77. In the production of maize, the minimum frequency was 2 and the maximum 6 and it has a mean of 5.51. In the case of ploughing by RUMPSTAD 2WT, all the fields were ploughed under dry condition. The maximum and minimum frequency of ploughing were 2 and 1, respectively. The average frequency of ploughing was 1.6.

The optimal land preparation condition for both RAMPTSTUD and control (Rice) practice was determined by the host farmers. Hence, the ploughing frequency was variable between fields. For the rice treatment, the ploughing frequency of rice ranges between 2 and 5. The mean was 3.77. In the production of maize, the minimum frequency was 2 and the maximum 6 and it has a mean of 5.51. In the case of ploughing by RUMPSTAD 2WT, all the fields were ploughed under dry condition. The maximum and minimum frequency of ploughing were 2 and 1, respectively. The average frequency of ploughing was 1.6.

Farm operations, labor rate and payments in Birr

Even though family labour is commonly used for farm operation in rural household area, the opportunity cost of labour needs to be considered. The average labour rate and time requirement for each farm activity presented in Table 4.

Even though family labour is commonly used for farm operation in rural household area, the opportunity cost of labour needs to be considered. The average labour rate and time requirement for each farm activity presented in Table 4.

| No | Farm operations | Labour rate (ETB/ Man-day) | Man-day/ha | ||

| maize | Rice | maize | Rice | ||

| 1 | Ploughing (oxen) | 70 | 150 | 4 man days | 4 |

| 2 | Seeding | ||||

| Ploughman | 70 | 100 | 13 man days | 4 | |

| Fertilizer applicator | 50 | 50 | 4 man days | 4 | |

| Seeder man | 50 | 50 | 4 maydays | 4 | |

| 3 | Weeding | 50 | 100 | 8 manday | 10 |

| 4 | Harvesting | 60 | 80 | 24 man days | 8 |

| 5 | Threshing* | 60 | 100 | 12 man days | 10 |

Table 4: Labour rate for different farm activities.

Oxen commonly worked from 4 to 9 hours/day, depending mainly on the time available for soil preparation. ILCA's survey results have shown that animal power uses or crop-related work averaged more than 1000 hours/farm/year. Most of this power was supplied by oxen, but other cattle were sometimes employed for thrashing. About 63 to 70% of the total animal power input was for seedbed preparation and planting, with approximately 350hours/oxen pair used for these purposes (ILCA, 1984)

With regard to working days in the highlands of Ethiopia, there are 2 holidays (Saturday and Sunday) per week and 8 days per month which equals 96 days per year. In these days no agricultural works are done. Besides these, there are also about 8 holidays per month and 96 days per year when agricultural works or practices are not done. Hence, there is a total of 192 days which our farmers do not use annually for agricultural practices. That means, about 173 days are available for agricultural work. All these days actually may or may not be used for agricultural practices. According to Melaku (2011) oxen are only used for some 60 pairs days of work each year. Anderson., et al. (1985) and Grysees., et al. (1984) have shown that farmers in highland Ethiopia work their oxen for some 450 pair hours) this is equivalent to 2 months per year. However, the work potential of drought cattle can be 8-10 months as is estimated in India (Pathak and Gill, 1984).

Cost Calculation (TFC, TVC & ATC)

Fixed costs (costs of owning a pair of oxen and ploughing equipment)

The annual costs of owning a pair of oxen and ploughing equipments are estimated. According to the result obtained in the study area, it costs about 14743.15 ETB to own and maintain a pair of oxen per year (Table 5) and based on the survey, the working life of oxen is estimated to be about 7 years.

Fixed costs (costs of owning a pair of oxen and ploughing equipment)

The annual costs of owning a pair of oxen and ploughing equipments are estimated. According to the result obtained in the study area, it costs about 14743.15 ETB to own and maintain a pair of oxen per year (Table 5) and based on the survey, the working life of oxen is estimated to be about 7 years.

| No | Item | Annual Costs |

| 1 | I. Depreciation | |

| Oxen (they maintain their value) | 0 | |

| Initial cost of plough | 13700 | |

| Working years or life | 7 | |

| Sales price | 7500 | |

| Depreciation cost | 885.71 | |

| 2 | II. Interest | |

| Average annual investment = 11410.575 | 1939.79 | |

| Interest rate = 17% | ||

| 3 | III. Feed & management | 9303.76 |

| 4 | IV. Shade construction for oxen | 2594.16 |

| Total | 14743.15 |

Table 5: Annual costs of owning a pair of oxen.

Similarly, an annual cost of owning oxen ploughing equipment is about 210.35 ETB. Therefore, the total annual cost of owning a pair of oxen and oxen ploughing equipment is about 14953.5 ETB (Table 6).

| No | Plough tool (shear & Wegel) | Annual Costs |

| 1 | initial cost of plough=255.75 | 51.59 |

| Working years or life=14 | ||

| Annual depreciation= 233.75-0/14 | ||

| 2 | Interest | 22 |

| Average annual investment = 255.75/2* 0.17= 21.73 | ||

| Interest rate = 17% | ||

| 3 | Annual Maintenance | 35.5 |

| Yoke, beam, handle, miran, digir, and others | ||

| Initial cost =260.55 | 66.26 | |

| Working life/years=5.1 | ||

| Depreciation= | ||

| 4 | Interest | 22 |

| Average annual investment = 22.14675 | ||

| Interest rate = 17% | ||

| 5 | Annual Maintenance | 13 |

| Total | 210.35 |

Table 6: Annual costs of owning oxen ploughing equipments.

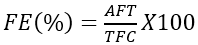

Break-even analysis (BEA) of oxen ownership Vs oxen hiring

The average annual cost of owning a pair of oxen found to be 14953.5 ETB (Table4 and 5). This cost is fixed irrespective of the size of land ploughed. Hence, as the size of land ploughed increases the rate of ploughing cost (ETB/ha) decreases. Therefore, in order to estimate the maximum ploughing potential of a pair of oxen in the study area, the average working days per year has to be known. In doing so, the average yearly working days of drought oxen was collected in the study area and it was found to be 60 days per year. Similar results were reported by Gryseels and Anderson (1983) who explained that, oxen only worked for about 60 days a year and the rest of the time they do not use for productive agricultural purposes. Hence, considering the average yearly working days (60 days for drought oxen), it requires 16 days to plough a hectare of land 4 times (average ploughing frequency). This implies that a pair of oxen can only sustain 3.5 ha/year ((60days/year)/(16days/ha)).

The average annual cost of owning a pair of oxen found to be 14953.5 ETB (Table4 and 5). This cost is fixed irrespective of the size of land ploughed. Hence, as the size of land ploughed increases the rate of ploughing cost (ETB/ha) decreases. Therefore, in order to estimate the maximum ploughing potential of a pair of oxen in the study area, the average working days per year has to be known. In doing so, the average yearly working days of drought oxen was collected in the study area and it was found to be 60 days per year. Similar results were reported by Gryseels and Anderson (1983) who explained that, oxen only worked for about 60 days a year and the rest of the time they do not use for productive agricultural purposes. Hence, considering the average yearly working days (60 days for drought oxen), it requires 16 days to plough a hectare of land 4 times (average ploughing frequency). This implies that a pair of oxen can only sustain 3.5 ha/year ((60days/year)/(16days/ha)).

In the study area, the average oxen hiring cost was about 200 Birr per day and it takes about 4 days to till one hectare of land only once. This implies that it costs about 800 Birr to till a hectare of land once. The average ploughing frequency is about 4 times; hence, it would take about 16 days to till a hectare of land. This again implies that it costs about 3200 Birr/ha.

The cost per hectare of owning oxen (animals and equipment come down as the area cultivated increases (economies of scale the figure shows that, the cost of ploughing for 4.5 ha for both modalities, hiring and owning oxen, is the same. Moreover, the figure shows that the cost of ploughing for a land less than 4.5 hectares, oxen hiring is cheaper than oxen owning. Hence, if a farmer has less than 4.5 ha, it is advisable to hire oxen for ploughing than owning oxen, irrespective of the other factors.

Break-even analysis (BEA) of tractor ownership Vs tractor hiring

In order to understand the charge for ploughing their field or transporting their crops or undertaking any other task, it is necessary to understand the total cost to own and operate the equipment on an hourly basis (Heney, 2009). The first thing to do is to work out the annual costs of simply owning the machinery; i.e. the fixed costs. These include depreciation, housing, insurance, road tax and the interest you are paying on any loan (Table 7).

In order to understand the charge for ploughing their field or transporting their crops or undertaking any other task, it is necessary to understand the total cost to own and operate the equipment on an hourly basis (Heney, 2009). The first thing to do is to work out the annual costs of simply owning the machinery; i.e. the fixed costs. These include depreciation, housing, insurance, road tax and the interest you are paying on any loan (Table 7).

| No | Item | Cost (Birr) |

| 1 | Tractor | |

| Tractor drive (assumes the farmer to drive) | 0 | |

| Purchase price | = 187000 | |

| Salvage value = 20% of Purchase price | = 37400 | |

| Economic life | = 8years | |

| Tractor Depreciation = (187,000 – 37400)/8yrs | =18700 | |

| 2. | Interest estimated as 17% of average investment in machinery (187,000 +37400 / 2) x 17% |

19074 |

| 3 | Tractor shed(housing) depreciation = (10,000/10 yrs)**1 | 1000 |

| Total Fixed cost (ETB/ year) | 43860.4 |

Table 7: Annual Fixed costs of owning RUMPTSTAD 2Wheel –Tractor.

If this tractor was used for 10,000 hours (ASAE, 1990 and Pflucger, 1999,), the fixed costs per hour would be 43860.4/1250 hour that equals 35.10 Birr/hour. Also it is imperative to work out the variable costs. Here is an estimate based on the assumption that 2 wheel tractor its lifetime is used for 10, 000 or 12,000 hours. For these analyses 10,000 hours were used for the year (Table 8).

| No | Items | Hourly cost (ETB/hr) |

| 1 | liters of fuel cost (table-3, 1.29 lt/hr and $ birr 16.1/1t) | 20.8 |

| 2 | Oil and filters (estimated at 15% of fuel cost)*** | 3.1 |

| 3 | Repairs and spares (estimated as 5% of purchase price) =187,000 *0.05%= 9350 per year = 9350/1250=7.5ETB/hr |

7.5 |

| 4 | Operator cost | 25 |

| Total | 56.4 | |

Table 8: Variable costs of owning RUMPTSTAD 2Wheel –tractor.

*** Nebraska tractor test (Pflucger, 1994)

*** Nebraska tractor test (Pflucger, 1994)

Therefore, the variable cost per hour is 56.4 ETB. Based on these figures the total costs per hour add up to 91.5 ETB per hour. As it is depicted in Table 3, the average ploughing capacity of RUMPTSTAD 2WT in this trial was 0.06ha/hour and the average ploughing frequency was 1.6 times. Hence, the average cost of ploughing for a hectare of land becomes 2440ETB/ha ((91.5ETB/hour)/(0.06ha/hour) *1.6).

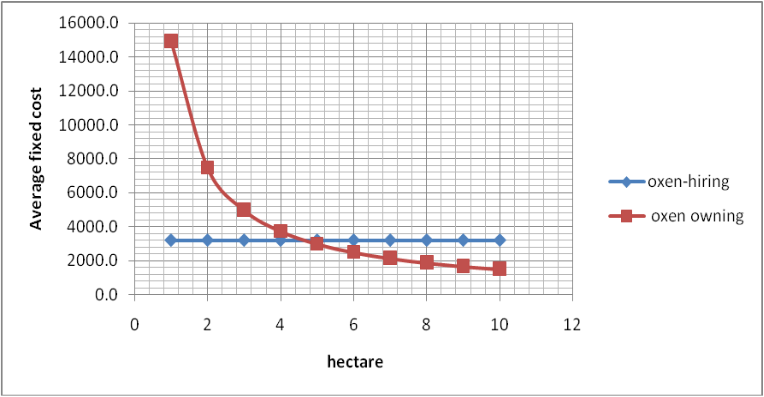

Comparison of oxen owning and tractor hiring

A comparative analysis between oxen ownership and tractor hiring was done which indicated that tractor hiring is still cheap as compared to holding or purchasing a pair of oxen for ploughing activity. The BEP in this analysis is four hectares of land (figure 3). Until this point, it is not worth to invest or purchase oxen for ploughing. Total hiring of tractor cost per year is cheaper than purchasing of oxen, though oxen ownership has its social and status of the society in the study area.

A comparative analysis between oxen ownership and tractor hiring was done which indicated that tractor hiring is still cheap as compared to holding or purchasing a pair of oxen for ploughing activity. The BEP in this analysis is four hectares of land (figure 3). Until this point, it is not worth to invest or purchase oxen for ploughing. Total hiring of tractor cost per year is cheaper than purchasing of oxen, though oxen ownership has its social and status of the society in the study area.

Partial Budget Analysis

The cost benefit analysis technique is a powerful tool if all the costs and all the benefits can be identified. The difficulty with it is that some of the costs and benefits are not easily quantified. Hence, partial analysis is a common tool to use in different farm plan decisions as it considers partial or part of the whole plan of the farm.

The cost benefit analysis technique is a powerful tool if all the costs and all the benefits can be identified. The difficulty with it is that some of the costs and benefits are not easily quantified. Hence, partial analysis is a common tool to use in different farm plan decisions as it considers partial or part of the whole plan of the farm.

In the partial budget analysis, cost calculation was done based on the same variable cost/hour. Only costs that vary are used for comparison of the two treatments, hence inputs which are common for all did not consider in the analysis (CIMMYT, 1988). From the survey data it is found that the number of working days per year is between 84-180 days (mean=129); however, from the past irrigation data the average irrigation days applicable in the area were found to be from 40-60 days. Therefore, for this analysis about 70-80 working days were used to calculate hourly cost of oxen ploughing. Hence, the total fixed cost of oxen ploughing per year is 14953.84 Birr/year and the average working hours per day is about 8 hours. Therefore, the average hour used per year is about 600 hours and the average fixed cost of a pair of oxen ploughing would be 24.92 Birr/ hour. The total gain obtained from use of 2 wheel tractor is about 24585.83 Birr and its loss are about 23076.52 Birr (Table 9). The value is used to estimate the weight of the grain from each plot. The market price for each seed was obtained from the nearest market center (farmer’s cooperatives).

Therefore, the net gain obtained from tractor use was about 1509.31 Birr. This trial experiment showed that, 2 wheel tractor ploughing has an increase in net income of farmers over oxen ploughing system in monetary terms. However, there are also disadvantages in terms of social and cultural value for the farmers (Table 9)

Conclusion and Recommendation

For farmers with relatively small holdings (less than 4.5 hectare of land) oxen owning is less profitable; therefore, it is good to use oxen hiring, if available. Oxen hiring is better than oxen owning and its breakeven point is at four hectare and beyond this it is good to rely on oxen purchase or owning. Tractor hiring is profitable for farmers than owning as it is not a profitable business for smaller holder farmers in the study area. Generally, it concluded that oxen hiring is profitable than oxen ownership, tractor hiring is profitable than oxen owning), tractor hiring is cheaper than tractor purchase. The partial budget analysis result also shows that RUMPTSTAD 2WT is more profitable than traditional ploughing on a yield basis compare to traditional oxen practice. Therefore, further promotion and popularization for wider adoption is imperative.

Acknowledgement

The authors thank financial support of Wageningen, The Netherlands and Tibebe General Trading (TGT), Addis Ababa, Ethiopia for providing the funds for the research work. The authors would also like to thank the developmental agents and district leaders, farmers in the community and field assistants for their provision and assistance for the constructive feedback for working with us throughout the survey time.

The authors thank financial support of Wageningen, The Netherlands and Tibebe General Trading (TGT), Addis Ababa, Ethiopia for providing the funds for the research work. The authors would also like to thank the developmental agents and district leaders, farmers in the community and field assistants for their provision and assistance for the constructive feedback for working with us throughout the survey time.

Funding

This research was financially supported by The Netherlands and Tibebe General Trading (TGT) Addis Ababa, Ethiopia.

This research was financially supported by The Netherlands and Tibebe General Trading (TGT) Addis Ababa, Ethiopia.

References

- Anderson F and Abiye Astatke. “Pond excavation using ox-drawn scoops in rural Ethiopia: The experience of two Peasant Associations in Debre Berhan area”. Highlands Programme Working Document, ILCA, Addis Ababa, Ethiopia (1985):

- Astewel Takele and Yihenew G Selassie. “Socio-economic analysis of conditions for adoption of tractor hiring services among smallholder farmers, Northwestern Ethiopia”. Cogent Food & Agriculture 4.1 (2018): 1453978.

- Aune JB., et al.“The ox ploughing system in Ethiopia: can it be sustained?” Outlook on Agriculture 30.4 (2001): 275-280.

- Burton W Pflucger. “Farm machinary cost, owen, lease or custom hirie. Extention from financial management specialist, incooperation with Lorry Modsen, Alan May, Curtis Hayt, and Ralph Motz extention area from managemnt agents”. SDSU Economics department (1994):

- Bukhari S., et al. “Mirani Performance of Selected Tillage Implements, Agricultural Mechanization in Asia, Africa and Latin America”. 19.4 (1988): 9-14.

- Celerina L and Maranan. “The consequences of small rice farm mechanization project comparative evaluation of tractor and Carabao use in rice land preparation”. Nueva Ecija, Philippines 91 (1982):

- CIMMYT. “From agronomic data to farmer recommendations, economic analysis”. (1988):

- FAO and UNIDO. “Agricultural Mechanization in Africa time for action: planning investment for enhanced agricultural productivity”. (2008):

- Faleye T., et al. “Improving small-farm productivity through appropriate machinery in Nigeria (Review)”. International Research Journal of Agricultural Science and Soil Science 2.9 (2012):386-389.

- Gryseels G., et al. “The use of single oxen for crop cultivation in Ethiopia”. Cooperative Agricultural Program Annual Report (1984):

- Gryseels G and Anderson FM. “Research on farm and livestock productivity in the central Ethiopian highlands: Initial results, 1977 – 1980”. Research Report 4 (1983):

- Jennifer Heney. “Explaining the finances of machinery ownership”. Rural Infrastructure and Agro-Industries Division Food and Agriculture Organization of the United Nations Rome Italy (2009):

- “International Livestock center for Africa (ILCA)”. Annual Report (1984):

- Larry K Bond and Richard Beard. “The cost of owning and operating farm machinery”. (1997):

- Melaku T. “Oxenization versus Tractorization: Options and Constraints for Ethiopian Framing System”. International Journal of Sustainable Agriculture 3.1 (2011): 11-20.

- Muhammad Yusuf Maamun. “Financial analysis of tractor purchase decision in south Sulawesi”. Department of agriculture economics (1991):

- Paman U., et al. “The Economic Potential of Tractor Hire Business in Riau Province, Indonesia; A Caa retse of Small Tractor Use for Small Rice Farms”. Agricultural Engineering International: the CIGR Ejournal XII (2010):

- Pathak., et al. “Management and utilization for work”. Paper presented to the Expert Consultation of Appropriate Use of Animal Energy in Africa and Asia (1984):

Citation:

Astewel Takele. “Comparative Evaluation of Rumptstad 2- Wheel Tractor and Oxen Ploughing System: A Case Study in

Northwest Ethiopia”. Innovative Techniques in Agriculture 3.2 (2018): 626-639.

Copyright: © 2018 Astewel Takele. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.