Research Article

Volume 2 Issue 5 - 2018

Effect of Different Drying Methods on Red Beet (Beta vulgaris) Quality

Food Science and Technology - Agricultural Industrialization Unit - Desert Research Center – Cairo –Egypt

*Corresponding Author: Amira M Shokry, Food Science and Technology - Agricultural Industrialization Unit - Desert Research Center – Cairo –Egypt.

Received: March 04, 2018; Published: March 17, 2018

Abstract

The greeting interest of consumers to preserve their crops in order to beat food deficiency and attain food security was a target to investigate a way to maintain red beet so as to use all over the year. The influence of oven, sun and microwave drying methods on nutrional values, total phenol, vitamin c, color and rehydration ratio of red beet root were studied. All the drying methods under investigation decreasing moisture content with enhancing the nutrional contents and resulted in dried red beet with excellent color and rehydration ratio. Microwave drying treatment improve both total phenol and vitamin c contents where the sun drying treatment outcome dried beet samples with perfect total phenol content but with a shortage in vitamin c content. The oven drying treatment produced dried red beet with a sensible total phenol and vitamin c contents. Finally, it could use the drying methods under investigation in preserving red beet and obtain dried red beet which can be used in food preparation especially infant food, also it could be consumed as a substitute of traditional snacks.

Keywords: Red beetroot; Beta vulgaris L., Microwave drying; Sun drying; Oven drying; Total phenol; Vitamin C and Rehydration ratio

Introduction

Rural people overcome the serious food shortages by diversifying their food sources even by growing a variety of crops or collecting of fruits and vegetable for consumption. Reducing in losing rate during post-harvest and marketing processes of fruits and vegetables become a very important task to reach the world’s food security (Tembo., et al. 2008; Akinnifesi., et al. 2006, 2008). In the same time the processing of fruits and vegetables for possible value adding products which could be progress farmer income is nearly negligible (Gokhale and Lele, 2014).

Food preservation purposed to increase the time for keeping food safe while holding over quality and nutrients. Fruits and vegetables play an important role in human diet and nutrition but are highly perishable due to their high moisture content, so decreasing the moisture content become an important task to increase shelf life of fruits and vegetables and promote food security (Singh., et al. 2013). Drying is one of the preservation methods ensuring microbial safety of biological products (Mathlouthi, 2001) where it used to reduce moisture content in the food matrix to a level that inactivate microbial activity and so increasing the shelf life of fruits and vegetables making them available throughout the year. So it presumes to be a suitable alternative for post-harvest management where the reduction of water activity by moisture removal leads to significant reduction of weight and volume, minimizing packaging, transportation and storage costs (Sagar and Suresh, 2010).

Sun and oven drying are the popular drying methods used in drying these food crops, sun drying being the most common practice (Matazu and Haroun, 2004). Microwave drying is an unconventional drying methods. There is a great interest in using this technology due to the high capacity of penetration of these waves, where the heat not only on the surface but also inside the food particles, so, it speeds up the drying process, reducing drying time resulting in improving the quality of the final dried product (Contreras., et al. 2008).

Red beet (Beta vulgaris) is botanically classified as an herbaceous biennial from Chenopodiaceae family (Gokhale and Lele, 2014). It is a traditional and popular vegetable in many parts of the world. They can be eaten raw, boiled, steamed and roasted. The nutritional benefits of red beet root are very well known, it also contributes to consumers’ health and wellbeing because it is known to be a rich source of powerful antioxidants and nutrients, and also, they are wealthy with vitamins A, B1, B2, B6 and C.

Moreover, they are an excellent source of calcium, magnesium, copper, phosphorus, sodium and iron. These root vegetables help protect against heart disease and certain cancers (Kavalcova., et al. 2015 and Singh., et al. 2013). These root vegetables help protect against heart disease and certain cancers (colon cancer) (Kapadia., et al. 1996). There is growing interest in the use of deep red beet roots as a natural food color, Ibraheem., et al. (2016) recommended that the addition of encapsulated pigment of red beet to the food models could be successively improved the food product color without adverse effects on the quality attributes.

Red beet root is not available throughout the year. Increase in awareness of red beet health benefits has focused attention of how to preserve its phytochemicals during storage. Subsequently, dehydration of red beet root is a preservation method used to develop value added products during the off-season. Drying methods impact the dried product quality (Kulkarni and Govindene, 1994; Waghmore., et al. 1999; Krokida and Maroulis, 2001). The removal of water by heat has been reported to affect the nutrient contents of food in various ways, where it can either increase the concentration of some nutrients by making them more available or decrease the concentration of some nutrients (Hassan., et al. 2007; Morris., et al, 2004; Ladan., et al. 1997).

Therefore, there is a growing need to optimize the process for achieving quality retention. For this consideration, oven, sun and microwave drying methods were investigated to study their effects on the nutrional values, total phenol, colour, and rehydration ratio of dried red beet roots.

Material and Methods

The root of red beet was obtained from Khmisa Farm, Siwa Research Station, Desert Research Center-Egypt. The red beet roots were washed, peeled and grated using a kitchen processor. Red beet root was dried using sun drying (SRB), oven (ORB), high power level microwave oven (HMRB) and the medium power level in microwave oven (MMRB) using microwave model NN-C988W made in japan with a 1800W powerful heater. The samples of each treatment will dried until it become crispy with attention to overturn the grated red beet every 20 minutes for the SRB and ORB treatments and every 2 minutes for both HMRB and MMRB treatments to avoid it burned during drying. The dried red beet was package in polyethylene bags and stored in refrigerator at 4°C until analyzed.

Analytical methods

Fresh and dried red beet treatments were analyzed for moisture, crude protein, ether extract, crude fiber and total ash according to the methods described in the A.O.A.C. (2000). The carbohydrate content was calculated by difference. Total phenol contents determined according to Singleton & Rossi (1965), Vitamin C determined according to Brubacher., et al. (1985) and Bajaj and Kaur (1981).

Fresh and dried red beet treatments were analyzed for moisture, crude protein, ether extract, crude fiber and total ash according to the methods described in the A.O.A.C. (2000). The carbohydrate content was calculated by difference. Total phenol contents determined according to Singleton & Rossi (1965), Vitamin C determined according to Brubacher., et al. (1985) and Bajaj and Kaur (1981).

Quality assessment of dried red beet

Tow physical parameters (color and rehydration ratio) were used to estimate the quality of fresh and dried red beet treatments. Color was measured by Chroma meter (Konica Minolta, model CR 410, Japan) calibrated with a white plate and light trap supplied by the manufacturer at Cairo University Research Park (CURP), Faculty of Agriculture. Color was expressed using the CIE L, a, and b color system (CIE, 1976). A total of three spectral readings were taken for each sample on different locations of the LD muscle. Lightness (L*) (dark to light), the redness (a*) values (reddish to greenish). The yellowness (b*) value (yellowish to bluish) was estimated.

Tow physical parameters (color and rehydration ratio) were used to estimate the quality of fresh and dried red beet treatments. Color was measured by Chroma meter (Konica Minolta, model CR 410, Japan) calibrated with a white plate and light trap supplied by the manufacturer at Cairo University Research Park (CURP), Faculty of Agriculture. Color was expressed using the CIE L, a, and b color system (CIE, 1976). A total of three spectral readings were taken for each sample on different locations of the LD muscle. Lightness (L*) (dark to light), the redness (a*) values (reddish to greenish). The yellowness (b*) value (yellowish to bluish) was estimated.

Rehydration ratio defined as the rehydrated samples ratio of rewet weight sample to the weight of dry sample and determined by soaking 5g of dried sample in 100 mL boiling water for 30 min then cooled. The cooled content was filtered and weighed. Rehydration ratio calculated using the following equation as mentioned by Gokhale and Lele (2011):

Result and Discussion

Rehydration ratio = Weight of the rehydrated material

Weight of the dehydrated material

Weight of the dehydrated material

Effect of drying methods on the nutrional quality of dried red beet

The action of applying heat to a material in order to dry it does affect the nutritional qualities of the dried product (Onayemi, 1981), so it was important to evaluate the effect of the drying process under investigation on the nutrional values of the dried red beet.

The action of applying heat to a material in order to dry it does affect the nutritional qualities of the dried product (Onayemi, 1981), so it was important to evaluate the effect of the drying process under investigation on the nutrional values of the dried red beet.

Data presented in table (1) shows the decrement in moisture content in relation to drying time and found that the moisture percentage decreased from 76.75% in the FRB to 4.15% and 6.23% after 20 and 35 minute for HMRB and MMRB treatments, respectively, where it decreased to 5.38% and 5.26% after 4 and 8 hours for ORB and SRB treatments, respectively. Therefore, drying methods used under investigation affected the drying time and found that the Microwave drying method present a very excellent advantages over both SRB and ORB drying methods in taking down drying time. The same trend was obtained by Singh., et al. (2013) who mention that the red beet has been dried by five different temperature levels and moisture is lost in good extent but the microwave convection drying proved better than the other method in terms of reduced drying time and lower final moisture content.

However, the results showed that there was increment in the other nutrient components tested where the highest increment in ash, total fiber and total protein contents were obtained with the ORB treatment. The other treatments contain a considerable high percentage of ash, total fiber and total protein. Increasing in total carbohydrate content was registered with SRB and HMRB treatments followed by MMRB and ORB treatments, respectively. Finally, all dried treatments had an increment in ash, total fiber, total protein and total carbohydrate contents in comparison with the fresh samples. And so, the drying methods found to improve the nutrional content of the dried red beet.

| Proximate analysis | FRB | ORB | SRB | MMRB | HMRB |

| Moisture | 76.75 | 5.38 | 5.26 | 6.23 | 4.15 |

| Ash | 6.88 | 9.17 | 8.10 | 8.87 | 8.81 |

| Total Fibre | 3.67 | 7.68 | 5.31 | 5.69 | 5.59 |

| Total Protein | 5.59 | 13.26 | 12.67 | 12.00 | 12.94 |

| Total Lipid | 0.12 | 0.15 | 0.19 | 0.68 | 0.26 |

| Total Carbohydrate | 6.99 | 64.36 | 68.47 | 66.53 | 68.25 |

Table 1: Effect of drying methods on nutrional content of dried red beet.

(FRB) is fresh red beet samples, (ORB) is the oven dried red beet treatment, (SRB) is the sun dried red beet treatment, (MMRB) is the medium power microwave dried red beet treatment and (HMRB) is the high power microwave dried red beet treatment.

Morris., et al. (2004) illustrated that there are two processes occurring during drying, the addition of heat and the removal of moisture from the food. Nutritional losses during drying are more due to the application of heat than to the removal of moisture. Likewise Hassan., et al. (2007) and Ladan., et al. (1997) stated that the removal of water by heat has been reported to affect the nutrient contents of food where it can increase the concentration of some nutrients and making them more available. And so, the drying methods used under study found to improve the nutrional content of the dried red beetroot.

Effect of drying methods on the total phenol and vitamin C contents of dried red beet

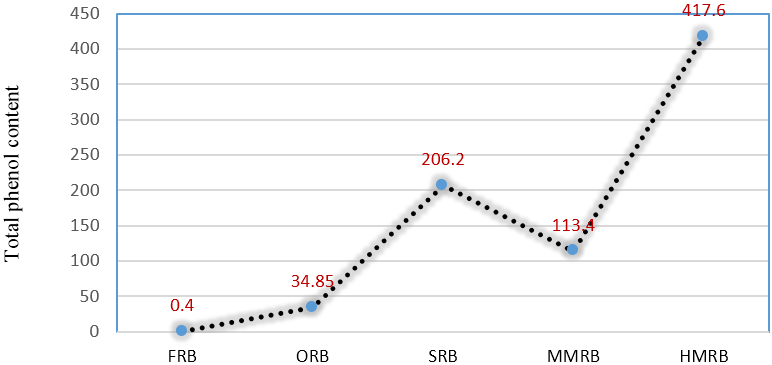

Figure (1) demonstrate the results obtained for TP contents of fresh and different dried red beet treatments. Dried red beet represented a higher recovery for TP content in comparison with the fresh samples. The highest value in TP occurred with the HMRB treatment (417.6 mg(GAE)/100g) sample followed by SRB (206.2 mg(GAE)/100g) and MMRB (113.4 mg(GAE)/100g), where the ORB treatment exhibit the lowest TP value (34.85 mg(GAE)/100g).

Figure (1) demonstrate the results obtained for TP contents of fresh and different dried red beet treatments. Dried red beet represented a higher recovery for TP content in comparison with the fresh samples. The highest value in TP occurred with the HMRB treatment (417.6 mg(GAE)/100g) sample followed by SRB (206.2 mg(GAE)/100g) and MMRB (113.4 mg(GAE)/100g), where the ORB treatment exhibit the lowest TP value (34.85 mg(GAE)/100g).

These results were in accordance with Hung and Duy, 2012 who mentioned that dried red beet is a good source of phenolics and stated that this may be attributed to the presence of the phenolic compounds primarily in red beet in bound form rather than in free form which it does not affected by thermal treatment because of their association with cell wall of vegetables. Furthurmore, Guldiken., et al. (2016) announced that drying process led to 36% higher TP contents in dried red beetroot compared to the fresh sample.

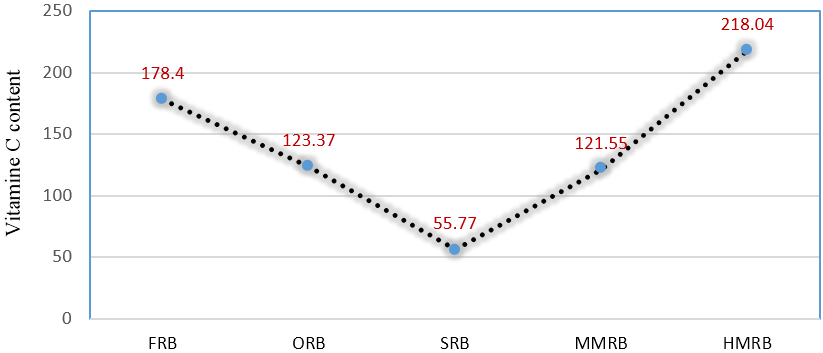

Data in figure (2) clarify that vitamin C content was affected by the drying methods under investigation. Loss in vitamin C content reported to be higher with the SRB treatments (55.77 mg/100g) where both ORB and MMRB treatments resulted in loss in vitamin C content but it was less than SRB treatment, whilst the HMRB treatments enhanced vitamin C (218.04 mg/100g) and that is in comparison with the fresh samples which appeared to have 178.4 mg/100g vitamin C. Idah., et al. (2010) concluded that there was a continuous decrease in the value of vitamin C as the drying time increase.

Similar observation have been reported by Ndawula. et al. (2004) who stated that the open sun drying method caused the greatest vitamin C loss due to the exposure of the drying fruits and vegetables to greater solar radiation particularly ultra violet (UV) rays and also the sun drying methods holding the moisture content for comparatively longer time in comparison with the other drying methods and this caused strengthen the enzymatic reactions and interaction of other constituents of the drying product leading to loss of vitamins.

Ozkan., et al. (2007) indicated that the reduction in the ascorbic acid levels by using microwave drying methods was recorded as dependent on drying time and microwave power level because the drying time depend on the microwave power level. And this explain the reduction in vitamin C content with MMRB treatment where there is a reinforcement in vitamin C content in HMRB treatment.

Effect of drying methods on color and rehydration ratio of dried red beet

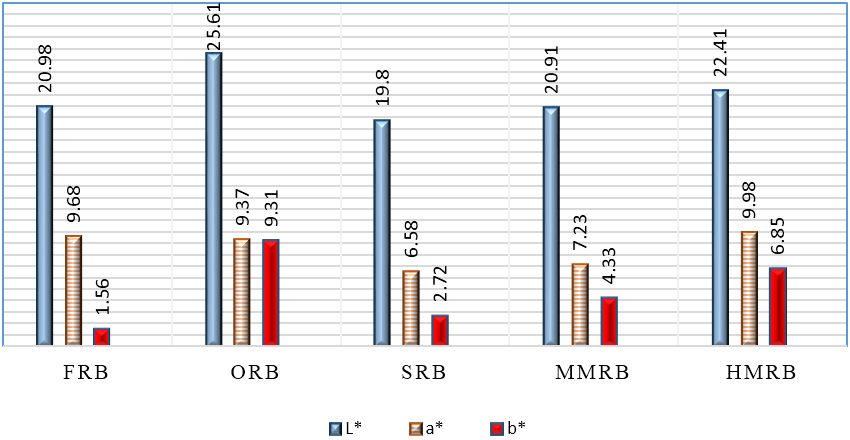

The color of the food surface is the first quality parameter evaluated by consumers and is critical in product acceptance, even before it is tasted. Color values were registered over to study the variation in color of different dried red beet treatments. From data in figure (3) we found that the L* values increased with ORB treatments followed by the HMRB and MMRB treatments while the SRB treatment recorded the lower L* value in comparison with the FRB treatments. The same trend of increment was also observed with the b* values where the highest b* values obtained with the ORB treatments followed by HMRB˃ MMRB˃SRB treatments compared to the FRB treatments. This is may be due to the yellow pigments are more stable than the red pigments and also, during the thermal treatment the betalains (the red pigment) converts to yellow due to thermochemical reactions (Carle and Stintzing, 2007).

The color of the food surface is the first quality parameter evaluated by consumers and is critical in product acceptance, even before it is tasted. Color values were registered over to study the variation in color of different dried red beet treatments. From data in figure (3) we found that the L* values increased with ORB treatments followed by the HMRB and MMRB treatments while the SRB treatment recorded the lower L* value in comparison with the FRB treatments. The same trend of increment was also observed with the b* values where the highest b* values obtained with the ORB treatments followed by HMRB˃ MMRB˃SRB treatments compared to the FRB treatments. This is may be due to the yellow pigments are more stable than the red pigments and also, during the thermal treatment the betalains (the red pigment) converts to yellow due to thermochemical reactions (Carle and Stintzing, 2007).

Also, it was observed that a* values for MMRB and SRB treatments was lower than the a* values of FRB treatments, respectively, where the a* values of both HMRB and ORB treatments were almost equal to the a* values of FRB treatments. This may be due to temperature sensitivity of red pigment as mentioned by Gokhale and Lele (2011).

Carle and Stintzing (2007) reference that, at higher drying temperature conversion of red to yellow pigments may happen but it may be masked by browning of the beet and so recompense the shortage in red color for the treatments that have high lightness and yellowness value since the Chroma meter records only the surface color and not the actual pigment content. The colour changes caused by the thermal treatment may be caused not only by the non-enzymatic browning reaction, but also by the destruction of pigments present in the foods López., et al. (2013).

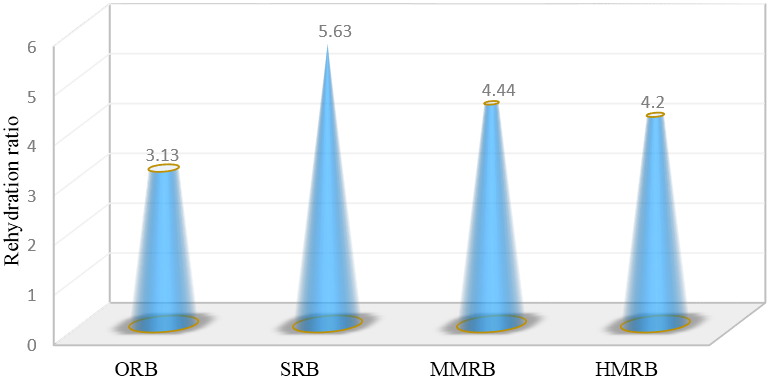

Rehydration ratio (Rr) is a way to evaluate the quality assessment of dried food (Lewicki, 1998). The high rehydration value means the high quality of dried food (Noomhorm 2007) and so, Rr is a key quality for the dried products (Garcia-Pascual., et al. 2006).

Data in figure (4) demonstrated that the SRB treatments exhibit the highest Rr followed by MMRB, HMRB and ORB treatments, respectively. Rajeswari., et al. (2011) observed a high rehydration ratio with sun drying methods. Noomhorm, (2007) display that the high rehydration ratio means the porous structure is allowing more water to reenter the cells, thus the pours structure of the SRB, HMRB and MMRB treatments supposed to be better than those of ORB treatment.

Conclusion

Based on the results obtained from the study, the drying methods used under investigation were be good as they all lowering final moisture content, enhanced the nutritional constituents and appear to have good color and rehydration ratio in the dried red beet compared to fresh sample. However, the microwave treatments proved to be better than the other methods in terms of minimize drying time, improved both total phenol and vitamin C contents in the dried red beet samples.

The SRB treatment enhanced the total phenol content but lowering vitamin C content compared with the other treatments, while the ORB samples though likely to have a perfect content of vitamin C and a reasonable level of total phenol content compared by the FRB samples. Whilst, to obtain fast drying, the microwave drying method which though to be more expensive is recommended followed by the oven drying method then the sun drying method which takes much longer drying time.

References

- Akinnifesi FK., et al. “Indigenous Fruit Trees in the Tropics: Domestication, Utilization and Commercialization. World Agroforestry Centre: Nairobi”. CAB International Publishing (2008): 438.

- Akinnifesi FK., et al. “Towards developing the miombo indigenous fruit trees as commercial tree crops in Southern Africa”. Forests, Trees and Livelihoods 16.1 (2006): 113-121.

- AOAC. Association of Official Analytical Chemist. Official methods of analysis. (18th edn). Washington DC. (2000).

- Bajaj KL and G Kaur. “Spectrophotometric determination of L-ascorbic acid in vegetables and fruits”. Analyst 106.1258 (1981): 117-120.

- Brubacher G., et al. “Methods for the determination of vitamin in food”. Applied Science Publishers (1985).

- Carle R and FC Stintzing. “Betalains-Emerging prospects for food scientists”. Trends in Food Science & Technology 18.10 (2007): 514-525.

- Contreras C., et al. “Influence of microwave application on convective drying: effects on drying kinetics, and optical and mechanical properties of apple and strawberry”. Journal of Food Engineering 88.1 (2008): 55-64.

- Garcia-Pascual P., et al. “Morchalla esculenta (morel) rehydration process modelling”. Journal of Food Engineering 72.4 (2006):346-353.

- Gokhale SV and SS Lele. “Betalain Content and Antioxidant Activity of Beta vulgaris: Effect of Hot Air Convective Drying and Storage”. Journal of Food Processing and Preservation 38.1 (2014): 585-590.

- Gokhale SV and SS Lele. “Dehydration of red beet root (Beta vulgaris) by hot air drying: Process optimization and mathematical modeling”. Food Science and Biotechnology 20.4 (2011): 955-964.

- Guldiken B., et al. “Home-Processed Red Beetroot (Beta vulgaris L.) Products: Changes in Antioxidant Properties and Bioaccessibility”. International Journal of Molecular Sciences 17.6 (2016): 858.

- Hung PV and TL Duy. “Effects of drying methods on bioactive compounds of vegetables and correlation between bioactive compounds and their antioxidants”. International Food Research Journal 19.1(2012): 327-332.

- Hassan SW., et al. “The Effect of Drying Method on the Nutrients and Non-Nutrients Composition of Leaves of Gynandropsis gynandra (Capparaceae)”. Asian Journal of Biochemistry 2 (2007): 349-353.

- Ibraheem AA., et al. “Improving red color of some food products using red beet powder”. International Journal of Science and Research 5.12 (2016): 798-805.

- Idah P AJ M usa and ST Olaieye. “Effect of temperature and drying time on some nutritional quality parameters of dried tomatos”. AU J of Technology 14.1 (2010): 25-32.

- Kapadia GJ., et al. “Chemoprevention of lung and skin cancer by Beta vulgaris (beet) root extract”. Cancer Letters 100.1-2 (1996): 211–214.

- Krokida MK and ZB Maroulis. “Structural properties of dehydrated products during rehydration”. International Journal of Food Science & Technology 36.5 (2001): 529-538.

- Kulkarni KD and N Govindene. “Crisp quality of two potato varieties: Effects of dehydration and rehydration”. Journal of the Science of Food and Agriculture 64.2 (1994): 205-210.

- Ladan MJ., et al. “Effect of solar drying on the nutrient composition of tomatoes”. Nigerian Journal of Renewable energy 5 (1997): 67-69.

- Lewicki PP. “Some remarks on rehydration of dried foods”. Journal of Food Engineering 36.1 (1998): 81-87.

- López J., et al. “Effect of dehydration temperature on physico-chemical properties and antioxidant capacity of goldenberry (Physalis peruviana L.)”. Chilean Journal of Agricultural Research 73 (2013): 293-299.

- Matazu IK and AA Haroun. “The effect of drying method on the nutrients and non- nutrients composition of the fruit of Hibiscus esculentus (Okra)”. Nigerian Journal of Renewable energy 11 (2004): 9-13.

- Mathlouthi M. “Water content, water activity, water structure and the stability of foodstuffs”. Food Control 12.7 (2001): 409-417.

- Morris A A Barnett and O Burrows. “Effect of processing on nutrient content of foods”. Cajarticles 37 (2004): 160-164.

- Ndawula J., et al. “Alterations in fruit and vegetable β-carotene and vitamin C content caused by open-sun drying, visqueen-covered and polyethylene-covered solar-dryers”. African Health Sciences 4.2 (2004):125-130.

- Noomhorm A. “Overview of dehydration method on quality of fruit and vegetables”. SWU Sci. J 23 (2007): 9-22.

- Onayemi O. “Post-harvest food loss management in Nigeria”. Industry and Environment 4 (1981): 5-8.

- Ozkan IA., et al. “Microwave drying characteristics of spinach”. Journal of Food Engineering 78 (2007): 577-583.

- Rajeswari P., et al. “Value addition to amaranthus green herbage through dehydration and drying”. Agricultural Science Research Journal 2 (2011): 348–350.

- Sagar VR and KP Suresh. “Recent advances in drying and dehydration of fruits and vegetables: a review”. Journal of Food Science and Technology 47.1 (2010): 15-26.

- Singh S., et al. ‘Microwave Convection Drying Characteristics of Beet Root (Beta Vulgaris L.) Using Modeling Equations for Drying”. Journal of Food Processing and Technology 4.9 (2013).

- Singleton VL and JA Rossi. “Colorimetry of total phenolics with phosphomolybdic phosphotungstic acid “reagents”. American Journal of Enology and Viticulture 16 (1965): 144-158.

- Tembo L., et al. “Blanching and drying period affect moisture loss and vitamin C content in Ziziphus mauritiana (Lamk.)” African Journal of Biotechnology 7.8 (2008): 3100-3106.

- Waghmore NV., et al. “Effect of pre-treatments, storage of potato and antioxidants on quality of potato chips prepared from cultivars grown in western Maharashtra”. Journal of Food Science and Technology 36 (1999): 49-51.

Citation:

Amira M Shokry. “Effect of Different Drying Methods on Red Beet (Beta vulgaris) Quality”. Nutrition and Food Toxicology 2.5

(2018): 451-458.

Copyright: © 2018 Amira M Shokry. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.