Research Article

Volume 2 Issue 3 - 2017

Effect of Size Reduction on Drying and Sensory Attributes of Osmodehydrofrozen Plantain Slices

1Centre for Entrepreneurship Development, Yaba College of Technology, Yaba, Lagos, Nigeria

2Department of Food Technology, Yaba College of Technology, Yaba, Lagos, Nigeria

3Department of Food Technology, Moshood Abiola Polytechnic, Ojere, Ogun State, Nigeria

4Centre for Entrepreneurship Development, Yaba College of Technology, Yaba, Lagos, Nigeria

5Centre for Entrepreneurship Development, Yaba College of Technology, Yaba, Lagos, Nigeria

2Department of Food Technology, Yaba College of Technology, Yaba, Lagos, Nigeria

3Department of Food Technology, Moshood Abiola Polytechnic, Ojere, Ogun State, Nigeria

4Centre for Entrepreneurship Development, Yaba College of Technology, Yaba, Lagos, Nigeria

5Centre for Entrepreneurship Development, Yaba College of Technology, Yaba, Lagos, Nigeria

*Corresponding Author: Oresanya Tolulope, Centre for Entrepreneurship Development, Yaba College of Technology, Yaba, Lagos, Nigeria.

Received: November 07, 2017; Published: November 29, 2017

Abstract

The study was conducted to investigate the effect of varying thicknesses: 2 mm, 4 mm and 6mm and 2 different osmotic media: Sucrose (50.4°Brix) and Saline solutions on the physical and sensory characteristics of ripe, slightly ripe and unripe plantain slices subjected to osmotic dehydration. Physical measurements were taken and parameters such as Moisture Content (MC), Solid Gained (SG) and Normalized Moisture Content (NMC) were determined. The osmotically dehydrated plantain slices (ODP slices) were kept under frozen storage for six weeks and then fried in vegetable oil. Sensory evaluation was conducted on the fried ODP slices using multiple comparison tests. There was significant difference in texture, colour, and aroma of the plantain slices against the reference sample. There was no significant difference in taste between the ODP slices and the reference sample. The rate of NMC and SG were found to be fastest in the slightly ripe and unripe slices immersed in sucrose medium with values of 0.67 and 0.78 for the unripe slices and 0.67 and 0.59 for slightly ripe slices. The extent of moisture loss depended on the concentration and composition of the medium, the thickness and the stage of ripening of the plantain but was found to be more in the slightly ripe slices at MC of 42.73 ± 0.47. Browning occurred in the ODP slices immersed in Sucrose solution during frying. Conclusively, the ODP slices from plantains at each stage of ripening showed different relationships for the MC, SG and NMC.

Keywords: Plantain; Osmotic Dehydration; Freezing, Osmodehydrofreezing; Normalised Moisture Content; Solid Gained

Introduction

Plantain (Musa parasidiaca) is an important staple food in the humid tropical zones of Africa, Asia, Central and South America [9]. It is an important food crop in Nigeria as it is either cooked in green form and eaten, left to ripen and fried in vegetable oil or roasted. It is a formidable food crop that provides important nutrition (25% carbohydrates, 10% calorie intake) for many millions of consumers. It is an important source of income for many small holder farmers who engage in compound or home gardens [5].

Plantains are usually harvested at green, pre-climacteric stage of maturity and once harvested; the fruit has short shelf life as it ripens very quickly [1]. At ambient tropical temperatures, plantain has an average market life of 1-10 days compared to several weeks for yam for instance [15]. In periods of bumper harvest, plantain fingers not utilized are usually lost to senescence [17]. This is usually as a result of uncontrolled respiration rate after harvest and inadequate storage conditions, processing as well as its high moisture content. Consequently, a great potential exists for the development of effective and efficient processing of fruits and vegetables, plantain not excluded.

Drying is an age-old method of preserving plantains in Nigeria as it reduces the moisture present in the food thus preventing the growth of microorganisms that could lead to food spoilage. Plantains that are preserved by drying can be kept at ambient temperature for long periods but the qualities of such products are negatively affected due to uncontrolled condition of dehydration [15,2].

Freezing has been known to be a good method of preservation of fruits though it causes changes in the flavour, color, texture and nutritional value and also physical damage that cause loss of turgor and textural changes [11]. Dehydrofreezing is the process by which a food is dehydrated to the desired moisture content and then frozen. This is well established as a commercial method of reducing cost of shipping, handling and storage of fruits and vegetables. It also provides convenience of use as compared with conventional freezing. Convective drying, vacuum osmotic drying and osmotic drying have been used in the dehydrofreezing of fruits and vegetables. Flavour and nutrition are largely influenced by the dehydration method used for the dehydrofreezing process [13]. The use of osmotic dehydration for partially reducing the moisture levels of fruits may prove worthwhile in tropical countries where there is a growing demand for dried whole fruits and fruit flavours for use in ice cream and soft drinks. The production of dehydrofrozen plantain chips through osmotic dehydration may lead to a desirable convenience product [10].

Therefore the aim of this study was to investigate the characteristics of osmodehydrated plantain slices kept under frozen storage.

Materials and Methods

All the raw materials were purchased from Idi-oro market in Lagos, Nigeria. Bunches of firm green mature plantain, slightly ripe plantain, ripe plantain as well as commercial grade sugar and salt were obtained.

Methods

Experimental Design

Variables

Variables

- Plantain – firm green, firm ripe light yellow, firm ripe yellow (3)

- Media – Salt, Sugar (2)

- Thicknesses – 2 mm, 4 mm, 6 mm (3)

Number of samples: 3 x 2 x 3= 18 samples.

Preparation of Osmotic Media (Sucrose and Salt)

A modified method of [2] was employed in the preparation of the sucrose osmotic medium. The solution for osmotic dehydration was prepared by dissolving 7.7 kg of sucrose in 6kg of water. The sugar and water are added simultaneously and stirred until the sugar is completely dissolved and a brix level of 50.4°Brix is achieved. This was read on the prism surface of the Abbe Refractometer. The solution was kept overnight at room temperature before being used to ensure complete dissolution of the sugar.

A modified method of [2] was employed in the preparation of the sucrose osmotic medium. The solution for osmotic dehydration was prepared by dissolving 7.7 kg of sucrose in 6kg of water. The sugar and water are added simultaneously and stirred until the sugar is completely dissolved and a brix level of 50.4°Brix is achieved. This was read on the prism surface of the Abbe Refractometer. The solution was kept overnight at room temperature before being used to ensure complete dissolution of the sugar.

For the salt media solution, 2.020 kg of salt was dissolved in 10 kg of water (lukewarm) and stirred until completely dissolved.

Preparation of Plantain slices for Osmotic Dehydration

The plantain fruit was manually peeled and sliced using a kitchen slicer. The thicknesses of the slices are varied and measured as 2mm, 4mm and 6mm using a micrometer screw gauge. The slices were weighed and divided into portions in deep bowls to be used. The osmotic medium was then poured into each of the bowls to cover the slices in the ratio of 1 to 5 (1:5) of fruit to water by weight [7]. The osmodehydrated samples are taken out of the media at intervals of 1 hour for 6 hours, rinsed quickly under water to remove adhering osmotic solution, blotted dry with tissue paper and weighed [10].

The plantain fruit was manually peeled and sliced using a kitchen slicer. The thicknesses of the slices are varied and measured as 2mm, 4mm and 6mm using a micrometer screw gauge. The slices were weighed and divided into portions in deep bowls to be used. The osmotic medium was then poured into each of the bowls to cover the slices in the ratio of 1 to 5 (1:5) of fruit to water by weight [7]. The osmodehydrated samples are taken out of the media at intervals of 1 hour for 6 hours, rinsed quickly under water to remove adhering osmotic solution, blotted dry with tissue paper and weighed [10].

Following osmotic treatment, the samples are weighed at each time interval and then dried in a hot air oven at 105°C to constant weight [3].

Analyses

The percentage moisture content, solid content and solid gained were determined according to the following simple relations (6):

The percentage moisture content, solid content and solid gained were determined according to the following simple relations (6):

Percentage Moisture Content = W0 – W1 x 100 (1)

W0

W0

Solid content S, (%) = 100 – moisture content (2)

Solid gain, SG = S–So (3)

So

So

Where: S, So is the weight of the sample at time interval and the final weight of the solid sample respectively.

Normalised Moisture Content (NMC) was calculated with respect to the initial moisture content (6):

NMC = M (4)

Mo

Mo

Where: Mo and M are the initial and final moisture contents.

The above equations were based on the assumption that the amount of solids leaching out of the samples during pre-concentration is negligible. That is, it is assumed that the samples loose only water and gain solids.

The above equations were based on the assumption that the amount of solids leaching out of the samples during pre-concentration is negligible. That is, it is assumed that the samples loose only water and gain solids.

The results obtained were then subjected to statistical analysis of variance (ANOVA) and Duncan test. After osmotic treatment the samples are packed in air tight polyethylene bags, sealed and placed under frozen storage for a storage periods of 6 weeks of storage at a temperature of -18°C.

Sensory Evaluation

Sensory evaluation was carried out on the osmotically treated plantain slices, using fresh plantain slices from each stage of ripening as reference sample with all the samples fried in hot vegetable oil. Vertical sensory analysis was carried out on the samples. The three thicknesses were kept constant. The samples from the sixth storage week for the two osmotic media were evaluated for each of the plantain at their different ripening stages. A panel of 20 trained judges was used to evaluate the fried products for each plantain at its different stages of ripening for differences in colour, texture and aroma. A 9-point hedonic scale was used to determine the overall acceptability of the osmotically treated plantain samples. Results obtained were also subjected to statistical analysis: ANOVA and Duncan tests.

Sensory evaluation was carried out on the osmotically treated plantain slices, using fresh plantain slices from each stage of ripening as reference sample with all the samples fried in hot vegetable oil. Vertical sensory analysis was carried out on the samples. The three thicknesses were kept constant. The samples from the sixth storage week for the two osmotic media were evaluated for each of the plantain at their different ripening stages. A panel of 20 trained judges was used to evaluate the fried products for each plantain at its different stages of ripening for differences in colour, texture and aroma. A 9-point hedonic scale was used to determine the overall acceptability of the osmotically treated plantain samples. Results obtained were also subjected to statistical analysis: ANOVA and Duncan tests.

Result and Discussion

Moisture Content

Firm Ripe Light Yellow Plantain Slices Osmotically Dehydrated in Sucrose solution (50.4 °Brix) and Saline solution: Available moisture content of firm ripe slightly yellow ODP slices showed a trend of reducing steadily as dehydration progressed as can be observed from Table 1. Across rows and within columns of the table, it was observed that there was significant difference between the samples immersed in each media at the different dehydration times. At the 6th hour, ODP slices of 2mm thickness in sucrose medium had the lowest moisture content of 42.73 ± 0.47 indicating that the moisture content of the sample reduced rapidly compared to the ODP slices of 6mm in the sucrose medium that had the highest value of 49 ± 0.28. This indicated that amount of moisture removed depends on the thickness of the slices. Moisture is bound within the solid matrix in many ways (capillaries, physico-chemical bonding to the solid constituents). According to [12], it was observed that the rate of diffusion of water from any material made up of tissues (such as plantain slices) depends upon factors such as temperature and concentration of osmotic solution, size and geometry of material solution to material mass ratio and the level of agitation of the solution.

Firm Ripe Light Yellow Plantain Slices Osmotically Dehydrated in Sucrose solution (50.4 °Brix) and Saline solution: Available moisture content of firm ripe slightly yellow ODP slices showed a trend of reducing steadily as dehydration progressed as can be observed from Table 1. Across rows and within columns of the table, it was observed that there was significant difference between the samples immersed in each media at the different dehydration times. At the 6th hour, ODP slices of 2mm thickness in sucrose medium had the lowest moisture content of 42.73 ± 0.47 indicating that the moisture content of the sample reduced rapidly compared to the ODP slices of 6mm in the sucrose medium that had the highest value of 49 ± 0.28. This indicated that amount of moisture removed depends on the thickness of the slices. Moisture is bound within the solid matrix in many ways (capillaries, physico-chemical bonding to the solid constituents). According to [12], it was observed that the rate of diffusion of water from any material made up of tissues (such as plantain slices) depends upon factors such as temperature and concentration of osmotic solution, size and geometry of material solution to material mass ratio and the level of agitation of the solution.

|

Thickness 2 mm |

Thickness 4 mm |

Thickness 6 mm |

|||

| Time (Hr) | Sucrose | Saline | Sucrose | Saline | Sucrose | Saline |

| 0 | 64.19 ± 0.30a(c) | 64.19 ± 0.30a(a) | 55.36 ± 0.30a(c) | 55.36 ± 0.30a(c) | 60.25 ± 0.30a(b) | 60.25 ± 0.30a(b) |

| 1 | 56.29 ± 0.28b(c) | 62.56 ± 0.31b(a) | 52.14 ± 0.25b(e) | 51.24 ± 0.25b(f) | 54.80 ± 0.51b(d) | 58.49 ± 0.25b(b) |

| 2 | 52.40 ± 0.39c(d) | 62.46 ± 0.48b(a) | 51.81 ± 0.34b(d) | 50.65 ± 0.35b(e) | 53.18 ± 0.39bc(c) | 56.65 ± 0.30bc(b) |

| 3 | 50.10 ± 0.30cd(d) | 58.11 ± 0.17b(a) | 48.51 ± 0.33bc(e) | 50.30 ± 0.36b(d) | 52.49 ± 0.31bc(c) | 53.85 ± 0.06cd(b) |

| 4 | 49.58 ± 0.25cd(c) | 52.22 ± 0.31c(b) | 48.31 ± 0.36bc(e) | 48.96 ± 0.83bc(d) | 52.29 ± 0.18bc(c) | 53.19 ± 0.75cd(b) |

| 5 | 47.60 ± 0.48d(c) | 51.18 ± 0.20c(b) | 47.41 ± 0.19bc(c) | 46.50 ± 0.15c(d) | 51.63 ± 0.37c(bc) | 52.21 ± 0.38de(a) |

| 6 | 42.73 ± 0.42e(f) | 48.56 ± 0.47d(c) | 47.35 ± 0.19c(d) | 45.59 ± 0.28c(e) | 49.40 ± 0.28c(a) | 49.11 ± 0.11e(b) |

Means with the same letter in bracket across rows are not significantly different at P˂ 0.05

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 1: Changes in Moisture Content of Osmotically Dehydrated Plantain Slices (Firm Ripe Light Yellow) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 1: Changes in Moisture Content of Osmotically Dehydrated Plantain Slices (Firm Ripe Light Yellow) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Firm Ripe Yellow Plantain Slices Osmotically Dehydrated in Sucrose solution (50.4°Brix) and Saline solution: Available moisture also reduced steadily although at a slower pace as observed from Table 2. Across rows and within columns of the tables, there was significant difference between the samples immersed in each solution at the different thicknesses at each dehydration time. ODP slices of 6mm thickness in saline medium at the 6th hour had the highest moisture content of 55.43 ± 0.27 while the ODP slices of 4mm thickness in sucrose medium was found to have the lowest moisture content of 49.35 ± 0.27. Comparing these values with those obtained in the firm ripe light yellow ODP slices, it was observed that moisture content reduced more rapidly in the slightly ripe ODP slices than in the ripe ODP slices. This indicated that the degree or stage of ripening of the plantain has effect on the rate at which moisture is removed from the sample.

| Thickness 2 mm |

Thickness 4 mm |

Thickness 6 mm |

||||

| Time (Hr) | Sucrose | Saline | Sucrose | Saline | Sucrose | Saline |

| 0 | 60.00 ± 0.30a(c) | 60.00 ± 0.30a(c) | 67.46 ± 0.30a(b) | 67.46 ± 0.30a(b) | 68.93 ± 0.30a(a) | 68.93 ± 0.30a(a) |

| 1 | 59.52 ± 0.38b(e) | 58.67 ± 0.16b(f) | 60.50 ± 0.37b(d) | 65.27 ± 0.31b(b) | 61.14 ± 0.14b(c) | 66.46 ± 0.19b(a) |

| 2 | 58.42 ± 0.15c(d) | 57.62 ± 0.34c(e) | 59.45 ± 0.18c(c) | 63.57 ± 0.25c(a) | 60.52 ± 0.40c(b) | 63.18 ± 0.18c(a) |

| 3 | 57.13 ± 0.09d(c) | 55.72 ± 0.06d(d) | 55.64 ± 0.18d(d) | 62.27 ± 0.19cd(a) | 56.43 ± 0.20d(c) | 60.30 ± 0.22d(b) |

| 4 | 54.51 ± 0.25d(d) | 54.69 ± 0.23d(d) | 55.36 ± 0.16d(c) | 56.59 ± 0.36d(b) | 54.54 ± 0.30e(d) | 59.64 ± 0.25de(a) |

| 5 | 53.89 ± 0.32f(c) | 52.58 ± 0.30e(d) | 51.63 ± 0.36e(e) | 55.29 ± 0.11d(b) | 53.36 ± 0.19ef(cd) | 56.29 ± 0.28e(a) |

| 6 | 49.56 ± 0.32f(c) | 49.88 ± 0.32f(c) | 49.35 ± 0.27f(d) | 51.45 ± 0.24e(b) | 49.56 ± 0.30f(c) | 55.43 ± 0.27f(a) |

Means with the same letter in bracket across rows are not significantly different at P˂ 0.05

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 2: Changes in Moisture Content of Osmotically Dehydrated Plantain (Firm Ripe Yellow) Slices 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 2: Changes in Moisture Content of Osmotically Dehydrated Plantain (Firm Ripe Yellow) Slices 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Firm Green Mature Plantain Slices Osmotically Dehydrated in Sucrose solution (50.4°Brix) and Saline solution: For the firm green mature ODP slices, a trend of steady reduction of available moisture was also observed as shown in Table 3. Across rows and within columns, there was significant difference between the samples immersed in each media at different thicknesses at each dehydration time. At the 6th hour, ODP slices of 2mm thickness in sucrose medium had the lowest moisture content of 46.23 ± 0.86 while the ODP slices of 6mm thickness in saline medium had the highest moisture content of 55.48 ± 0.64. In comparison with values obtained from the slightly ripe and ripe ODP slices, it was observed that the moisture content was driven out more quickly in the slightly ripe than in the ripe or unripe slices in the sucrose medium.

| Thickness 2 mm |

Thickness 4 mm |

Thickness 6 mm |

||||

| Time (Hr) | Sucrose | Saline | Sucrose | Saline | Sucrose | Saline |

| 0 | 69.51 ± 0.30a(a) | 69.51 ± 0.30a(a) | 63.65 ± 0.30a(b) | 63.65 ± 0.30a(b) | 62.49 ± 0.30a(c) | 62.49 ± 0.30a(c) |

| 1 | 59.45 ± 0.34b(b) | 62.64 ± 0.33b(a) | 58.26 ± 0.37c(d) | 62.21 ± 0.23b(a) | 56.65 ± 0.34b(d) | 62.24 ± 0.41a(a) |

| 2 | 58.37 ± 0.37c(c) | 58.28 ± 0.36c(c) | 55.17 ± 0.37c(d) | 60.40 ± 0.51c(b) | 55.18 ± 0.33c(d) | 61.33 ± 0.39b(a) |

| 3 | 54.56 ± 0.37d(d) | 56.21 ± 0.47d(c) | 53.57 ± 0.35d(e) | 57.61 ± 0.42d(b) | 52.44 ± 0.35d(f) | 58.91 ± 0.74c(a) |

| 4 | 53.59 ± 0.41de(c) | 52.23 ± 0.28e(d) | 51.50 ± 0.46e(e) | 56.42 ± 0.27de(b) | 52.51 ± 0.29d(d) | 57.57 ± 0.30d(a) |

| 5 | 48.17 ± 0.30e(f) | 51.90 ± 0.20ef(c) | 50.40 ± 0.28e(d) | 52.51 ± 0.43e(b) | 49.42 ± 0.48e(e) | 56.42 ± 0.38e(a) |

| 6 | 46.23 ± 0.86f(e) | 50.42 ± 0.28f(c) | 49.76 ± 0.25f(d) | 51.19 ± 0.22f(b) | 49.24 ± 0.16e(d) | 55.48 ± 0.64f(a) |

Means with the same letter in bracket across rows are not significantly different at P˂ 0.05

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 3: Changes in Moisture Content of Osmotically Dehydrated Plantain (Firm Green Mature) Slices 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 3: Changes in Moisture Content of Osmotically Dehydrated Plantain (Firm Green Mature) Slices 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Generally, moisture content was observed to have reduced more rapidly for each plantain at each thickness in the sucrose medium than in the saline medium. This indicated that the sucrose medium had a higher driving force than in the saline medium. According to [8], the higher the concentration of the osmotic solution, the higher the difference between osmotic potential of the material and the osmotic solution, and so the higher the driving force for the process, leading to products with lower moisture content. This behavior has also been reported by [4] and [13].

Solid Gained

Firm Ripe Light Yellow Plantain Slices Osmotically Dehydrated in Sucrose solution 50.4°Brix and Saline solution: Amount of solid gained was found to increase steadily as dehydration period progressed as shown in table 4. Across rows, there was significant difference between the ODP slices of each thickness in the osmotic media at each dehydration time. At each hour, ODP slices of 2 mm thickness in sucrose medium had the highest solid gained content with the highest value being 0.59 at the 6th hour.

Firm Ripe Light Yellow Plantain Slices Osmotically Dehydrated in Sucrose solution 50.4°Brix and Saline solution: Amount of solid gained was found to increase steadily as dehydration period progressed as shown in table 4. Across rows, there was significant difference between the ODP slices of each thickness in the osmotic media at each dehydration time. At each hour, ODP slices of 2 mm thickness in sucrose medium had the highest solid gained content with the highest value being 0.59 at the 6th hour.

| Thickness 2 mm |

Thickness 4 mm |

Thickness 6 mm |

||||

| Time (Hr) | Sucrose | Saline | Sucrose | Saline | Sucrose | Saline |

| 1 | 0.21e(a) | 0.03d(d) | 0.09b(c) | 0.10d(c) | 0.13c(b) | 0.03c(d) |

| 2 | 0.32d(a) | 0.04d(e) | 0.09b(d) | 0.13cd(c) | 0.17bc(b) | 0.08c(d) |

| 3 | 0.39c(a) | 0.17c(c) | 0.17a(c) | 0.13cd(d) | 0.19bc(b) | 0.16b(c) |

| 4 | 0.41bc(a) | 0.33b(b) | 0.17a(d) | 0.17bc(d) | 0.19bc(c) | 0.18b(c) |

| 5 | 0.49b(a) | 0.36b(b) | 0.19a(d) | 0.21ab(c) | 0.21ab(c) | 0.20b(d) |

| 6 | 0.59a(a) | 0.42a(b) | 0.20a(e) | 0.24a(d) | 0.26a(d) | 0.27a(c) |

Means with the same letter in bracket across rows are not significantly different at P ˂ 0.05

Means with the same letter within columns are not significantly different at P ˂ 0.05

Table 4: Changes in Solid Gained Content of Osmotically Dehydrated Plantain Slices (Firm Ripe Light Yellow) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Means with the same letter within columns are not significantly different at P ˂ 0.05

Table 4: Changes in Solid Gained Content of Osmotically Dehydrated Plantain Slices (Firm Ripe Light Yellow) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Within columns, there was significant difference as the amount of solid gained was found to increase more rapidly in the ODP slices of 2 mm thickness in sucrose medium. These results indicated that thickness has an effect on the rate or amount of solid gained by the sample during the osmotic dehydration process.

Firm Ripe Yellow Plantain Slices Osmotically Dehydrated in Sucrose solution 50.4°Brix and Saline solution: The amount of solid gained was found to also increase steadily over the period of dehydration as shown in table 5. Across rows, there was significant difference between the ODP slices of each thickness in the osmotic media at each dehydration time. At each hour, ODP slices of 6mm in sucrose solution had the fastest solid gained rate having the highest value of 0.617 at the 6th hour. Within columns, there was significant difference as the amount of solid gained was observed to be higher in the sucrose medium than in the saline medium indicating that the type and concentration of medium used has an effect on the amount of solid gained by the sample.

| Thickness 2 mm |

Thickness 4 mm |

Thickness 6 mm |

||||

| Time (Hr) | Sucrose | Saline | Sucrose | Saline | Sucrose | Saline |

| 1 | 0.040f(d) | 0.003f(e) | 0.203f(b) | 0.053f(d) | 0.249f(a) | 0.081f(c) |

| 2 | 0.037e(d) | 0.051e(d) | 0.247b(d) | 0.116e(c) | 0.287e(a) | 0.112e(c) |

| 3 | 0.070d(f) | 0.108d(e) | 0.360d(b) | 0.164d(d) | 0.401d(a) | 0.287d(c) |

| 4 | 0.130c(d) | 0.131c(d) | 0.375c(b) | 0.330c(c) | 0.463c(a) | 0.304c(c) |

| 5 | 0.155b(e) | 0.178b(e) | 0.488b(b) | 0.379b(d) | 0.501b(a) | 0.417b(c) |

| 6 | 0.257a(e) | 0.250a(e) | 0.552a(b) | 0.50a(c) | 0.617a(a) | 0.430a(d) |

Means with the same letter in bracket across rows are not significantly different at P˂ 0.05

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 5: Changes in Solid Gained Content of Osmotically Dehydrated Plantain Slices (Firm Ripe Yellow) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 5: Changes in Solid Gained Content of Osmotically Dehydrated Plantain Slices (Firm Ripe Yellow) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Firm Green Mature Plantain Slices Osmotically Dehydrated in Sucrose solution 50.4°Brix and Saline solution: The amount of solid gained was found to also increase steadily over the dehydration period as can be seen in table 6. Across rows, there was significant difference between the ODP slices of each thickness in the osmotic media at each osmotic media at each dehydration time. At each hour the ODP slices of 2 mm in the sucrose medium had the highest solid gained rate with the highest value of 0.78 at the 6th hour.

| Thickness 2 mm |

Thickness 4 mm |

Thickness 6 mm |

||||

| Time (Hr) | Sucrose | Saline | Sucrose | Saline | Sucrose | Saline |

| 1 | 0.33d(a) | 0.24c(b) | 0.14d(d) | 0.04d(e) | 0.17c(c) | 0.003b(f) |

| 2 | 0.38d(a) | 0.38b(b) | 0.23c(c) | 0.10d(e) | 0.19c(d) | 0.024b(f) |

| 3 | 0.49c(a) | 0.45b(b) | 0.29bc(c) | 0.18c(e) | 0.24bc(d) | 0.11a(f) |

| 4 | 0.54c(b) | 0.45b(b) | 0.35ab(c) | 0.20c(e) | 0.27b(d) | 0.13a(f) |

| 5 | 0.70b(a) | 0.61a(b) | 0.37a(c) | 0.31b(d) | 0.35a(c) | 0.17a(e) |

| 6 | 0.78a(a) | 0.65a(b) | 0.39a(c) | 0.35a(d) | 0.35a(d) | 0.18a(e) |

Means with the same letter in bracket across rows are not significantly different at P˂ 0.05

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 6: Changes in Solid Gained Content of Osmotically Dehydrated Plantain Slices (Firm Green Mature) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 6: Changes in Solid Gained Content of Osmotically Dehydrated Plantain Slices (Firm Green Mature) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Within columns, there was significant difference as the rate of solid gained observed to be the most rapid in the ODP slices of 2 mm thickness in the sucrose solution while ODP slices of 6mm in saline solution gained solids at a slower rate.

Generally unripe ODP slices showed a trend of gaining solids fastest in sucrose medium than in the saline medium compared to the slightly ripe or ripe ODP slices. This can be attributed to the fact that starch present in the unripe slices had not yet been hydrolyzed to sugar and as moisture is removed, the ODP slices absorbed solids at a faster rate than in the slightly ripe or rip which were already saturated with sugar.

A comparison of the results of MC and SG indicated that the values of SG are much lower than MC and this is significant since the main objective of osmotic dehydration is to reduce the moisture content with a minimal solid gain. This observation is consistent with the findings of [16] who worked on West Indian Cherry.

Normalized Moisture Content

Firm Ripe Light Yellow Plantain Slices Osmotically Dehydrated in Sucrose solution 50.4°Brix and Saline solution: Normalized Moisture Content (NMC) is a factor that describes the rate at which moisture is removed from the sample during osmotic dehydration.

Firm Ripe Light Yellow Plantain Slices Osmotically Dehydrated in Sucrose solution 50.4°Brix and Saline solution: Normalized Moisture Content (NMC) is a factor that describes the rate at which moisture is removed from the sample during osmotic dehydration.

From table 7, slightly ripe ODP slices showed a trend of reducing rapidly within the 6 hours of dehydration. Across the rows, there was significant difference between the ODP slices of each thickness in the osmotic media at each dehydration time. ODP slices of 2 mm thickness in sucrose solution showed a trend of reducing more rapidly than the other ODP slices in sucrose and saline media having the lowest value of 0.67 at the 6th hour.

| Thickness 2 mm |

Thickness 4 mm |

Thickness 6 mm |

||||

| Time (Hr) | Sucrose | Saline | Sucrose | Saline | Sucrose | Saline |

| 1 | 0.88a(c) | 0.98a(a) | 0.93a(b) | 0.92a(b) | 0.92a(b) | 0.98a(a) |

| 2 | 0.86ab(e) | 0.98a(a) | 0.93a(c) | 0.90ab(d) | 0.89b(d) | 0.96a(b) |

| 3 | 0.84b(c) | 0.88b(b) | 0.89b(a) | 0.89bc(a) | 0.87b(bc) | 0.90b(a) |

| 4 | 0.77c(d) | 0.81c(c) | 0.86c(b) | 0.87c(b) | 0.86c(b) | 0.89b(a) |

| 5 | 0.74d(f) | 0.80c(e) | 0.85c(b) | 0.84d(c) | 0.83d(c) | 0.88b(a) |

| 6 | 0.67e(e) | 0.76d(d) | 0.84c(a) | 0.81e(b) | 0.83d(a) | 0.78c(c) |

Means with the same letter in bracket across rows are not significantly different at P ˂ 0.05

Means with the same letter within columns are not significantly different at P ˂ 0.05

Table 7: Changes in Normalised Moisture Content of Osmotically Dehydrated Plantain Slices (Firm Ripe Light Yellow) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Means with the same letter within columns are not significantly different at P ˂ 0.05

Table 7: Changes in Normalised Moisture Content of Osmotically Dehydrated Plantain Slices (Firm Ripe Light Yellow) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

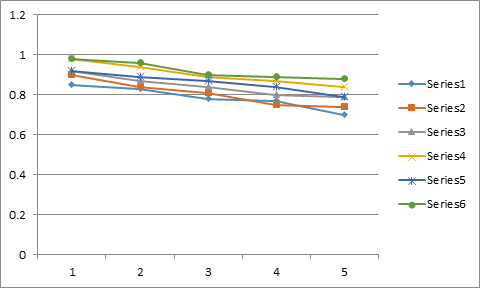

KEY:

SERIES 1: 2 mm Sucrose SERIES 2: 2 mm Saline SERIES 3: 4 mm Sucrose

SERIES 4: 4 mm Saline SERIES 5: 6 mm Sucrose SERIES 6: 6 mm Sucrose

Figure 1: Normalized Moisture Content of Osmotically Dehydrated Slightly Ripe Plantain Slices Of 2 mm, 4 mm and 6 mm (Sucrose 50.4° Brix and Saline Solution)

SERIES 1: 2 mm Sucrose SERIES 2: 2 mm Saline SERIES 3: 4 mm Sucrose

SERIES 4: 4 mm Saline SERIES 5: 6 mm Sucrose SERIES 6: 6 mm Sucrose

Figure 1: Normalized Moisture Content of Osmotically Dehydrated Slightly Ripe Plantain Slices Of 2 mm, 4 mm and 6 mm (Sucrose 50.4° Brix and Saline Solution)

Within columns, 2 mm sucrose ODP slices decreased more rapidly compared with the 4mm sucrose ODP slices that had the highest value of 0.84 at the 6th hour thus indicating that the rate at which moisture is removed depends on the thickness of the slices.

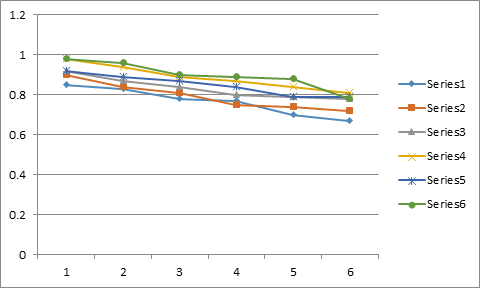

Firm Ripe Yellow Plantain Slices Osmotically Dehydrated in Sucrose solution 50.4°Brix and Saline solution: In table 8, the trend of NMC for the ODP slices of the ripe plantain was slightly different. Across rows, there was significant difference between the ODP slices of each thickness in the osmotic media at each dehydration time. The ODP slices of 6mm in sucrose solution showed a trend of reducing more rapidly than the other ODP slices having the lowest value of 0.74 along with the ODP slices of 4 mm in sucrose solution. Within the columns, ODP slices of 4 mm in sucrose solution decreased more rapidly compared to the other ODP slices which decreased steadily. This also indicated that the rate of moisture depends on the type of medium used as well as the thickness of the sample slices.

| Thickness 2 mm |

Thickness 4 mm |

Thickness 6 mm |

||||

| Time (Hr) | Sucrose | Saline | Sucrose | Saline | Sucrose | Saline |

| 1 | 1.00a(a) | 0.98a(b) | 0.90a(c) | 0.97a(b) | 0.89a(c) | 0.96a(b) |

| 2 | 0.98a(a) | 0.97a(b) | 0.88a(e) | 0.94b(c) | 0.87a(e) | 0.92b(d) |

| 3 | 0.95b(a) | 0.93b(b) | 0.83b(d) | 0.92c(b) | 0.82b(d) | 0.87c(c) |

| 4 | 0.91c(a) | 0.91b(a) | 0.82b(d) | 0.84c(c) | 0.79c(e) | 0.86c(b) |

| 5 | 0.90c(a) | 0.87c(b) | 0.77c(d) | 0.82c(c) | 0.78c(d) | 0.81d(c) |

| 6 | 0.85d(a) | 0.84d(b) | 0.74d(e) | 0.78d(d) | 0.74d(e) | 0.81d(c) |

Means with the same letter in bracket across rows are not significantly different at P˂ 0.05

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 8: Changes in Normalised Moisture Content of Osmotically Dehydrated Plantain Slices (Firm Ripe Yellow) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 8: Changes in Normalised Moisture Content of Osmotically Dehydrated Plantain Slices (Firm Ripe Yellow) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

KEY:

SERIES 1: 2 mm Sucrose SERIES 2: 2 mm Saline SERIES 3: 4 mm Sucrose

SERIES 4: 4 mm Saline SERIES 5: 6 mm Sucrose SERIES 6: 6 mm Sucrose

Figure 2: Normalized Moisture Content of Osmotically Dehydrated Firm Ripe Yellow Plantain Slices of 2 mm, 4 mm and 6 mm (Sucrose 50.4°Brix and Saline Solution).

SERIES 1: 2 mm Sucrose SERIES 2: 2 mm Saline SERIES 3: 4 mm Sucrose

SERIES 4: 4 mm Saline SERIES 5: 6 mm Sucrose SERIES 6: 6 mm Sucrose

Figure 2: Normalized Moisture Content of Osmotically Dehydrated Firm Ripe Yellow Plantain Slices of 2 mm, 4 mm and 6 mm (Sucrose 50.4°Brix and Saline Solution).

| Thickness 2 mm |

Thickness 4 mm |

Thickness 6 mm |

||||

| Time (Hr) | Sucrose | Saline | Sucrose | Saline | Sucrose | Saline |

| 1 | 0.85a(d) | 0.90a(c) | 0.92a(b) | 0.98a(a) | 0.92a(b) | 0.98a(a) |

| 2 | 0.83ab(e) | 0.84b(e) | 0.87a(d) | 0.94b(b) | 0.89b(c) | 0.96a(a) |

| 3 | 0.78b(e) | 0.81bc(d) | 0.84b(c) | 0.89c(a) | 0.87bc(b) | 0.90b(a) |

| 4 | 0.77b(e) | 0.75c(f) | 0.80c(d) | 0.87c(b) | 0.84c(c) | 0.89b(a) |

| 5 | 0.70c(e) | 0.74c(d) | 0.79c(c) | 0.84d(b) | 0.79d(c) | 0.88b(a) |

| 6 | 0.67d(d) | 0.72d(c) | 0.78c(b) | 0.81e(a) | 0.79d(b) | 0.78d(b) |

Means with the same letter in bracket across rows are not significantly different at P˂ 0.05

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 9: Changes in Normalized Moisture Content of Osmotically Dehydrated Plantain Slices (Firm Green Mature) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

Means with the same letter within columns are not significantly different at P˂ 0.05

Table 9: Changes in Normalized Moisture Content of Osmotically Dehydrated Plantain Slices (Firm Green Mature) 2 mm, 4 mm and 6 mm (Sucrose Solution 50.4°Brix and Saline Solution).

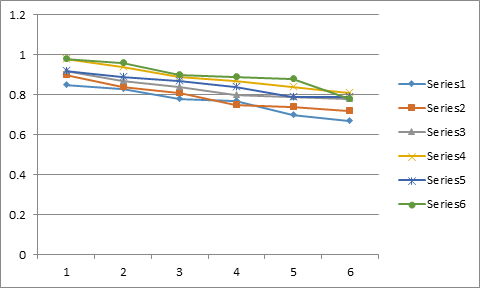

KEY:

SERIES 1: 2 mm Sucrose SERIES 2: 2 mm Saline SERIES 3: 4 mm Sucrose

SERIES 4: 4 mm Saline SERIES 5: 6 mm Sucrose SERIES 6: 6 mm Sucrose

Figure 3: Normalized Moisture Content of Osmotically Dehydrated Firm Green Mature Plantain Slices of 2 mm, 4 mm and 6 mm (Sucrose and Saline Solution).

SERIES 1: 2 mm Sucrose SERIES 2: 2 mm Saline SERIES 3: 4 mm Sucrose

SERIES 4: 4 mm Saline SERIES 5: 6 mm Sucrose SERIES 6: 6 mm Sucrose

Figure 3: Normalized Moisture Content of Osmotically Dehydrated Firm Green Mature Plantain Slices of 2 mm, 4 mm and 6 mm (Sucrose and Saline Solution).

Within the columns, the NMC for the ODP slices of 2mm thickness in sucrose solution decreased more rapidly than the others especially the ODP slices of 4mm thickness which had the highest value of 0.81 at the 6th hour of dehydration. This also indicated that the rate at which moisture is removed depends on the thickness, the medium used and the degree of ripening of the plantain sample. It was also observed that the rate at which water was removed from the samples increased with processing time. As the processing time increased, the NMC was found to reduce steadily. This trend was also reported by [16].

Generally, the NMC for slightly ripe, ripe and unripe ODP slices at each thickness in the media used showed a trend of decreasing steadily with a tendency to level off towards the end of each dehydration process. This was in agreement with the results obtained by [6].

Sensory Results on the Fried Plantain Chips Prepared by Osmodehydrofreezing of Plantain Slices in Osmotic Media: Sucrose and Saline Solution: Results of the sensory analysis carried out on the fried ODP slices (Table 10), showed that there was significant difference between the untreated fresh plantain slices and the ODP slices in terms of colour. The ODP slices immersed in sucrose solution were darker as a result of caramelization while the ODP slices immersed in saline solution were lighter than the reference sample.

In terms of texture and aroma, there was significant difference between the ODP slices and the reference sample as the 2 mm slices were crispier than the 4mm and 6mm samples in sucrose and saline media. For taste, a trend was observed in which there was no significant difference between the ripe, slightly ripe and unripe ODP slices immersed in the sucrose medium against the reference sample, while there was significant difference in the slices immersed in the saline medium.

For overall acceptability, it was observed that the ripe and slightly ripe ODP slices were better accepted than the unripe ODP slices [Table 10].

| Form | Media | Sample | Colour | Texture | Aroma | Taste | Overall acceptability |

| RIPE | SUCROSE | 1 (2 mm) | 3.59 ± 0.09cd | 3.40 ± 0.21c | 3.00 ± 0.26c | 4.41 ± 0.12a | 3.70 ± 0.47d |

| 2 (4 mm) | 3.80 ± 0.14ef | 2.80 ± 0.25de | 2.45 ± 0.28de | 3.25 ± 0.23c | 2.65 ± 0.52ef | ||

| 3 (6 mm) | 3.80 ± 0.17ef | 3.15 ± 0.18cd | 2.95 ± 0.16cd | 2.12 ± 0.05e | 2.75 ± 0.17e | ||

| SALINE | 4 (2 mm) | 4.15 ± 0.08b | 3.60 ± 0.20b | 3.45 ± 0.21bc | 2.23 ± 0.19e | 4.15 ± 0.45c | |

| 5 (4 mm) | 4.80 ± 0.09a | 4.35 ± 0.17a | 4.35 ± 0.25a | 3.12 ± 0.27cd | 7.35 ± 0.35a | ||

| 6 (6 mm) | 3.95 ± 0.15cd | 3.45 ± 0.18bc | 3.55 ± 0.20b | 2.06 ± 0.15f | 5.05 ± 0.38b | ||

| SLIGTHLY RIPE | SUCROSE | 1 (2 mm) | 3.65 ± 0.11e | 2.05 ± 0.09e | 1.75 ± 0.10e | 3.33 ± 0.14c | 2.10 ± 0.12de |

| 2(4mm) | 4.00 ± 0.21c | 2.50 ± 0.15d | 4.30 ± 0.15a | 4.03 ± 0.11a | 2.10 ± 0.19de | ||

| 3 (6 mm) | 3.85 ± 0.15d | 2.75 ± 0.14c | 2.00 ± 0.13de | 3.85 ± 0.14b | 2.20 ± 0.16d | ||

| SALINE | 4 (2 mm) | 4.40 ± 0.15abc | 3.30 ± 0.15bc | 2.85 ± 0.11c | 2.83 ± 0.15d | 3.70 ± 0.16c | |

| 5 (4 mm) | 4.45 ± 0.14ab | 3.45 ± 0.15b | 3.55 ± 0.15bc | 2.32 ± 0.28e | 4.70 ± 0.15bc | ||

| 6 (6 mm) | 4.55 ± 0.15a | 4.00 ± 0.16ab | 3.85 ± 0.18b | 2.50 ± 0.08de | 6.25 ± 0.22a | ||

| UNRIPE | SUCROSE | 1 (2 mm) | 4.14 ± 0.23ab | 2.05 ± 0.23e | 2.55 ± 0.32d | 3.97 ± 0.09b | 2.50 ± 0.65f |

| 2 (4 mm) | 3.85 ± 0.23d | 2.45 ± 0.27d | 2.80 ± 0.26cd | 3.85 ± 0.06b | 2.60 ± 0.53e | ||

| 3 (6 mm) | 3.90 ± 0.20c | 3.60 ± 0.23a | 3.50 ± 0.26bc | 3.15 ± 0.09c | 3.50 ± 0.65c | ||

| SALINE | 4 (2 mm) | 3.95 ± 0.18b | 2.70 ± 0.28c | 3.45 ± 0.22bc | 3.56 ± 0.21bc | 2.90 ± 0.56d | |

| 5 (4 mm) | 3.50 ± 0.27e | 3.10 ± 0.30b | 3.80 ± 0.26b | 2.50 ± 0.12de | 3.95 ± 0.74b | ||

| 6 (6 mm) | 3.60 ± 0.28de | 3.50 ± 0.17ab | 2.15 ± 0.17c | 2.10 ± 0.16e | 4.50 ± 0.85a |

Means with the same letter within the columns are not significantly different at P ˂ 0.05

Table 10: Sensory Results on the Osmotically Dehydrated Plantain Slices of 2 mm, 4 mm And 6 mm in Sucrose and Saline Solution..

Table 10: Sensory Results on the Osmotically Dehydrated Plantain Slices of 2 mm, 4 mm And 6 mm in Sucrose and Saline Solution..

Conclusion

The findings of this research revealed that Osmotic dehydration helps to reduce the available moisture content without appreciably distorting the physical structure of the fruit. The extent of moisture loss depends on the composition and concentration of the osmotic medium, the stage of ripening of the plantain as well as the thickness of the plantain slices. Freezing was able to keep the ODP slices in good shape except for the change in colour (dark and bright) which was due to the effect of the osmotic media.

References

- Abiose SH., et al. “Biochemical changes during Fermentation of Plantain”. Nigerian Food Journal 2 (1994): 92-98.

- Ade-Omowaye BO., et al. “Osmotic Dehydration Behaviour of Red Paprika”. Journal of Food Science 67.5 (2001): 1790-1796.

- AOAC. “Official method of Analysis, 15th Ed. Arlington VA: Association of Official Analytical Chemists”. 930.04 (1990): 40-69.

- Hawkes J., et al. “Osmotic concentration of fruit slices prior to freeze dehydration”. Journal of Food Processing and Preservation 2.4 (1978): 265-284.

- IITA Annual Report. “Influence of Osmotic Agents on Drying Behaviour and Product Quality”. Journal of Food Science 50.5 (1993): 1217-1219.

- Lazarides HN., et al. “Freeze / Thaw Effect on Mass Transfer Rates during Osmotic Dehydration”. Journal of Food Science60.4 (1995): 826-857.

- Lerici CR., et al. “Osmodehydration of Fruits: influence of osmotic agents on drying behaviour and product quality”. International Journal of Food Science 50.5 (1985): 1217-1226.

- Mayor L., et al. “Relation between mechanical properties and structural changes during osmotic dehydration of pumpkin”.Food Research International 40.4 (2007): 448-460.

- Ogazi PO., et al. “Pilot scale dehydration of plantain pulp for flour production using cabinet dryer”. Nigerian Food Journal 8 (1990): 74-94.

- Okechukwu PE., et al. “Osmotic Dehydration of Plantain (Musa Spp) in Sugar Solution”. Nigerian Food Journal 3.1.2.3 (1985): 159-162.

- Otero LM., et al. “Preservation of microstructure in peach and mango during high pressure-shift freezing”. Journal of Food Science 62.5 (2000): 1039-1042.

- Rastogi NK., et al. “Evaluation of mass transfer Mechanism during Osmotic treatment of Plant materials”. Journal of Food Science 65.6 (2000): 1016-1021.

- Robbers M., et al. “Osmotic-Convective Dehydration Freezing Process for Drying Kiwifruit”. Journal of Food Science 62.5 (1997): 1039-1043.

- Sereno AM., et al. “Mass transfer coefficients during osmotic dehydration of apple in single and combined aqueous solutions of sugar and salt”. Journal of Food Engineering 47.1 (2001): 43-49.

- Shaun R., et al. “Improving the Storage Life of Plantain and Banana”. IITA Research Guide (1997):

- Silva MAC., et al. Mass transfer during the osmotic dehydration of West Indian Cherry”. LWT-Food Science and Technology45.2 (2012): 246-252.

- Ukwum ME., et al. “Production of Instant Plantain Flour, Sensory Evaluation and Physiochemical Changes during Storage”. Food Chemistry 42.3 (1991): 287-299.

Citation:

Oresanya Tolulope., et al. “Effect of Size Reduction on Drying and Sensory Attributes of Osmodehydrofrozen Plantain Slices”.

Innovative Techniques in Agriculture 2.3 (2017): 364-375.

Copyright: © 2017 Oresanya Tolulope., et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.