Research Article

Volume 2 Issue 4 - 2018

Effect of Processing Methods on the Acceptability of "Ekuru" Produced from Bambara Groundnut

1Department of Food Technology, Yaba College of Technology, Yaba, Lagos, Nigeria

2Centre for Entrepreneurship Development, Yaba College of Technology, Yaba, Lagos, Nigeria

3Department of Food Technology, Yaba College of Technology, Yaba, Lagos, Nigeria

2Centre for Entrepreneurship Development, Yaba College of Technology, Yaba, Lagos, Nigeria

3Department of Food Technology, Yaba College of Technology, Yaba, Lagos, Nigeria

*Corresponding Author: Olaleye Hannah, Department of Food Technology, Yaba College of Technology, Yaba, Lagos, Nigeria.

Received: November 03, 2017; Published: February 13, 2018

Abstract

This study was carried out to assess the effect of processing methods on the quality of ‘ekuru’ produced from bambara groundnut. Bambara groundnut seeds were processed into flour samples using different processing methods; sprouted-dehulled, sprouted-undehulled, unsprouted-dehulled and unsprouted-undehulled. The ‘ekuru’ was then produced from the flour samples obtained and the samples were subjected to chemical analysis, physical properties as well as sensory analysis using standard procedures. Results of proximate analysis showed that the nutritional composition of the samples was enhanced as a result of the germination of the seed. Tannin, trypsin inhibitor and phytic acid were reduced in the sprouted and dehulled sample which led to an increase in the protein. There were significant differences in the water absorption capacity, swelling power and bulk density of the flour samples. Unsprouted undehulled bambara nut flour yielded ekuru with the most acceptable ratings for taste, aroma and overall acceptability.

Keywords: Bambara Groundnut; ‘Ekuru’; Processing methods; Chemical Analysis; Physical Properties; Sensory Analysis

Introduction

Bambara groundnut (Vigna subterranea (L.) verdc.) is an indigenous African crop that is grown across the continent from Senegal to Kenya and from the Sahara to South Africa. It is a highly nutritious crop that plays an important role in the diet. It is cultivated primarily for its seeds, which are used as human food. In Africa, it is the third most commonly eaten legume after groundnut and cowpea [6]. It contains approximately 11.4% protein, 53.1% carbohydrate, 6.1% fat, 6.1% fibre, 4.4% ash, 0.097% calcium, 0.007% iron, 1.2% potassium and 0.003% sodium and this makes a well-balanced food with calorific value equal to that of a high quality cereal grain [2]. It also contains moderate amounts of B vitamins and small amounts of minerals and vitamin A. [7] reported that it is richer than groundnut in essential amino acids such as isoleucine, leucine, lysine, methionine, phenylalanine, threonine and valine. Bambara groundnut is a non-oily leguminous seed which contains only about 6% of ether extract therefore could not give a cash crop status, a great importance in food industry. In addition, the fatty acid content is predominantly linoleic, palmitic and linolenic acids [10].

Bambara groundnut is usually fried or boiled with salt, eaten as snack or pounded into flour and used in the preparation of soup, porridge and various fried or steamed food products such as ‘akara’, ‘moi-moi’ and ‘okpa’ in Nigeria, It also finds a use in the preparation of the local food drink ‘kunu’ and such dish as ‘tuwo’ [4]. Bambara groundnut, though considered an ideal food because of its nutrient composition, is still considered an under-utilized crop in Nigeria and the commercial use of its flour into numerous food products has remained unpopular. The utilization of its flour to prepare food products such as bakery goods, pasta, noodles, and snack foods will serve the purpose of improving the utilization of bambara nut in the food industry.

'Ekuru' is a cowpea based staple food in Nigeria and in some other West African countries. It is a popular food in Southern & Western part of Nigeria and it serves as a nutritional food in cultural, traditional and religious functions especially among the Yorubas in South West Nigeria. Although it is a steamed cowpea paste product like ‘moi-moi’, it is different in composition, preparation and it exhibits distinctive rheological properties [1]. The incorporation of air into the paste through whipping during its processing is an important operation which confers the unique fluffiness of the paste and it is considered as an important quality characteristic of the product. 'Ekuru' can be eaten with prepared sauce made of spices and seasoning or vegetable soup. However, most people prefer consuming it with Eko or Agidi which are also cereal based foods [11].

Many studies have reported earlier that the protein content of bambara groundnut contains higher quantities of the essential amino acid, methionine, than other grain legumes, while the oil content is less than half of the amount found in legumes such as cowpea and peanuts [13].

‘Ekuru’ is usually produced using cowpea but for the purpose of this research work, bambara groundnut was used in the production of ‘Ekuru’. The study was carried out to assess the effect of different processing methods (sprouting and dehulling) on the quality attributes and acceptability of ‘Ekuru’ produced from bambara groundnut.

Materials and Methods

Bambara groundnuts and pumpkin leaves were purchased at a local market in Mile 12, Lagos state, Nigeria.

Flour Processing

The bambara groundnut seeds were cleaned to remove dirt, broken seeds and other foreign materials. The seeds were then divided into 2 portions (A and B), one portion of seeds (A) was allowed to germinate for 96 hours and the other portion was kept aside. The germinated seeds were then carefully selected, rinsed and divided into 2, one part was rinsed and oven dried while the second part was dehulled, rinsed and then oven dried at 500c for 36 hours, milled, sieved and stored in polythene bags. The second portion of the bambara groundnut (B) was further divided into 2 parts. The first part was oven dried, milled, sieved and store in polythene bag while the second part was dehulled, dried and milled into fine powder sieved and store in a polythene bags [5]. The flour samples were coded as shown in Table 1.

The bambara groundnut seeds were cleaned to remove dirt, broken seeds and other foreign materials. The seeds were then divided into 2 portions (A and B), one portion of seeds (A) was allowed to germinate for 96 hours and the other portion was kept aside. The germinated seeds were then carefully selected, rinsed and divided into 2, one part was rinsed and oven dried while the second part was dehulled, rinsed and then oven dried at 500c for 36 hours, milled, sieved and stored in polythene bags. The second portion of the bambara groundnut (B) was further divided into 2 parts. The first part was oven dried, milled, sieved and store in polythene bag while the second part was dehulled, dried and milled into fine powder sieved and store in a polythene bags [5]. The flour samples were coded as shown in Table 1.

| Sample Code | Samples |

| S2DB | Sprouted dehulled Bambara nut flour |

| S2KB | Sprouted undehulled Bambara nut flour |

| U2DB | Unsprouted dehulled Bambara nut flour |

| U2UB | Unsprouted undehulled Bambara nut flour |

Table 1: Sample coding.

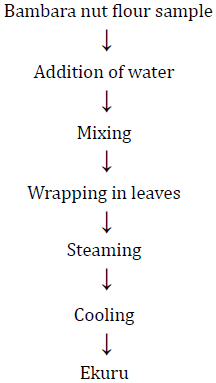

Production of ‘Ekuru’ sample

Five hundred grams of each flour sample was poured into a wide bowl and 50mls of water was added to it. The mixture was stirred vigorously for 10 minutes until the paste was fluffy. It was then scooped into pumpkin leaves and wrapped. The wraps were placed in a steamer with hot water and steamed for 40 minutes or until it solidified, and was deemed as well cooked [12].

Five hundred grams of each flour sample was poured into a wide bowl and 50mls of water was added to it. The mixture was stirred vigorously for 10 minutes until the paste was fluffy. It was then scooped into pumpkin leaves and wrapped. The wraps were placed in a steamer with hot water and steamed for 40 minutes or until it solidified, and was deemed as well cooked [12].

Analysis

Determination of Chemical Content of Bambara nut flour and ‘Ekuru’ samples

The bambara nut flour and the four samples of ‘Ekuru’ were analyzed in triplicate for moisture, crude protein, crude fibre, fat and ash using standard procedures of Association of Official Analytical Chemists [3]. The carbohydrate content was obtained by difference.

Determination of Chemical Content of Bambara nut flour and ‘Ekuru’ samples

The bambara nut flour and the four samples of ‘Ekuru’ were analyzed in triplicate for moisture, crude protein, crude fibre, fat and ash using standard procedures of Association of Official Analytical Chemists [3]. The carbohydrate content was obtained by difference.

Anti-Nutritional Analysis

Phytate content was determined using the method described by [8]. Two grams of sample was soaked in 20 ml of 0.2 N HCl and filtered. After filtration, 0.5 ml of the filtrate was mixed with 1ml ferric ammonium sulphate solution in a test-tube, boiled for 30 min in a water bath, cooled in ice for 15 min and centrifuged at 3000 g for 15 min. Then 1 ml of the supernatant was mixed with 1.5 ml of 2,2-pyridine solution and the absorbance read in a spectrophotometer. The concentration of phytic acid was then obtained by extrapolation from a standard curve using standard phytic acid solution.

Phytate content was determined using the method described by [8]. Two grams of sample was soaked in 20 ml of 0.2 N HCl and filtered. After filtration, 0.5 ml of the filtrate was mixed with 1ml ferric ammonium sulphate solution in a test-tube, boiled for 30 min in a water bath, cooled in ice for 15 min and centrifuged at 3000 g for 15 min. Then 1 ml of the supernatant was mixed with 1.5 ml of 2,2-pyridine solution and the absorbance read in a spectrophotometer. The concentration of phytic acid was then obtained by extrapolation from a standard curve using standard phytic acid solution.

The tannin content was determined using the method described by [9]. About 10 ml of 70% aqueous acetone was added to 200 mg of the sample in a bottle and it was properly covered. The bottle was then put in an ice-bath shaker for 2h at 30°C. The solution was centrifuged and the supernatant stored in ice. Then 0.2 ml of the supernatant was pipetted into 0.8 ml distilled water. Standard tannic acid solution was then prepared and 0.5 ml of Folin reagent was added to both sample and standard followed by 2.5 ml of 20% Na2CO3. The solutions were then vortexed and allowed to incubate for 40 min at room temperature after which the absorbance was read. The concentration of tannin in the sample was then estimated from the standard tannic acid curve.

Mineral Analysis

The mineral contents of the flour samples were determined by the procedure of [3]. Calcium, Magnesium, Sodium, Manganese, Zinc, Phosphorus, and Iron content was determined with Atomic Absorption Spectrophotometer (Thermo scientific S Series Model GE 712354, Sweden) after digesting with perchloric – nitric acid mixture (AOAC, 2000). Prior to digestion, 0.50 g of the samples were weighed into a 125 ml Erlenmeyer flask with the addition of perchloric acid (4 ml), concentrated HNO3 (25 ml) and concentrated sulphuric acid (2 ml) under a fume hood. The contents were mixed and heated gently in a digester (Buchi Digestion unit K-424) at low to medium heat on a hot plate under perchloric acid fume hood and heating was continued until dense white fume appeared. Heating was continued strongly for half a minute and then allowed to cool followed by the addition of 50 ml distilled water. The solution was allowed to cool and filtered completely with a wash bottle into a Pyrex volumetric flask and then made up with distilled water. The solution was then read on the Atomic absorption Spectrophotometer.

The mineral contents of the flour samples were determined by the procedure of [3]. Calcium, Magnesium, Sodium, Manganese, Zinc, Phosphorus, and Iron content was determined with Atomic Absorption Spectrophotometer (Thermo scientific S Series Model GE 712354, Sweden) after digesting with perchloric – nitric acid mixture (AOAC, 2000). Prior to digestion, 0.50 g of the samples were weighed into a 125 ml Erlenmeyer flask with the addition of perchloric acid (4 ml), concentrated HNO3 (25 ml) and concentrated sulphuric acid (2 ml) under a fume hood. The contents were mixed and heated gently in a digester (Buchi Digestion unit K-424) at low to medium heat on a hot plate under perchloric acid fume hood and heating was continued until dense white fume appeared. Heating was continued strongly for half a minute and then allowed to cool followed by the addition of 50 ml distilled water. The solution was allowed to cool and filtered completely with a wash bottle into a Pyrex volumetric flask and then made up with distilled water. The solution was then read on the Atomic absorption Spectrophotometer.

Sensory Evaluation

The ‘Ekuru’ samples were subjected to organoleptic analysis using a total of thirty semi-trained panelist drawn from staff and students of Yaba College of Technology, Lagos, Nigeria, for the evaluation. Each of the ‘Ekuru’ samples were placed in 30 coded clean white plates (30 gram per plate) and served at room temperature (28 ± 2°C) to the panelists in a sensory evaluation booth with fluorescent lights on. The assessors were requested to eat the ‘Ekuru’ and score each sample using a 9-point Hedonic scale; where 1 = extremely dislike and 9 = extremely like. Attributes evaluated include; color, taste, texture, aroma and overall acceptability. Water was provided for rinsing of their mouths in between tests to prevent carry-over of attributes.

The ‘Ekuru’ samples were subjected to organoleptic analysis using a total of thirty semi-trained panelist drawn from staff and students of Yaba College of Technology, Lagos, Nigeria, for the evaluation. Each of the ‘Ekuru’ samples were placed in 30 coded clean white plates (30 gram per plate) and served at room temperature (28 ± 2°C) to the panelists in a sensory evaluation booth with fluorescent lights on. The assessors were requested to eat the ‘Ekuru’ and score each sample using a 9-point Hedonic scale; where 1 = extremely dislike and 9 = extremely like. Attributes evaluated include; color, taste, texture, aroma and overall acceptability. Water was provided for rinsing of their mouths in between tests to prevent carry-over of attributes.

Statistical analysis

Data were reported as Mean ± SD. Statistical significance was established using One-Way Analysis of Variance (ANOVA) at 5% level of probability and differences between means were compared using Duncan Multiple range test. Statistical analysis was carried out using SPSS version 17 (SPSS Inc.) Chicago, IL USA.

Data were reported as Mean ± SD. Statistical significance was established using One-Way Analysis of Variance (ANOVA) at 5% level of probability and differences between means were compared using Duncan Multiple range test. Statistical analysis was carried out using SPSS version 17 (SPSS Inc.) Chicago, IL USA.

Results and Discussion

Tables 2 and 3 show the proximate composition of the bambara nut flour and ‘Ekuru’ samples produced from bambara nut flour with different processing methods. There were significant differences in the proximate analysis results. The moisture content of the flour and ‘Ekuru’ samples ranged from 6.02 to 7.98 and 7.44 to 15.16 respectively with the S2UB sample having the highest value for the flour and sample U2DB for the ‘Ekuru’ sample. The protein content of the flour and ‘Ekuru’ samples were significantly different with values ranging from 16.5 to 21.87 and 15.47 to 22.68 for the flour and ‘Ekuru’ samples respectively with sample S2UB having the highest value for both the flour and ‘Ekuru’ samples. The ash content ranged from 2.8 to 5.98 and 2.49 to 3.54 for the flour and ‘Ekuru’ samples respectively with sample U2UB having the highest value for the flour and sample S2UB having the highest value for the ‘Ekuru’ sample. Fat content ranged from 4.9 to 7.41 and 3.54 to 7.34 for the flour and ‘Ekuru’ samples respectively with the sample S2DB having the highest value for the flour and sample U2DB having the highest for the ‘Ekuru’ sample. The crude fibre content ranged from 0.15 to 1.19 and 0.15 to 0.34 for the flour and ‘Ekuru’ samples respectively with sample U2UB having the highest value for the flour samples and S2UB had the highest value for the ‘Ekuru’. The carbohydrate content ranged from 60.63 to 67.69 and 54.25 to 67.14 for the flour and ‘Ekuru' samples respectively with sample U2UB having the highest value for both the flour and ‘Ekuru’ samples.

| Sample | Moisture | Protein | Fat | Ash | Crude fibre | CHO |

| S2UB | 7.98 ± 0.01d | 21.87 ± 0.13d | 5.74 ± 0.01c | 3.44 ± 0.01b | 0.34 ± 0.00b | 60.63 ± 0.02a |

| S2DB | 6.45 ± 0.01b | 20.45 ± 0.01c | 7.41 ± 0.02d | 2.8 ± 0.01a | 0.15 ± 0.01a | 62.74 ± 0.04b |

| U2UB | 6.02 ± 0.01a | 16.5 ± 0.01a | 4.9 ± 0.01a | 5.98 ± 0.01d | 1.19 ± 0.01d | 67.69 ± 0.03d |

| U2DB | 6.10 ± 0.01c | 18.35 ± 0.01b | 5.10 ± 0.01b | 5.70 ± 0.01c | 0.75 ± 0.01c | 66.00 ± 0.01c |

Values are mean of triplicates ± standard deviation. Mean values with different superscripts within the same column are significantly different at 5% level.

Table 2: Proximate composition of Bambara Nut Flour.

Table 2: Proximate composition of Bambara Nut Flour.

| Sample | Moisture | Protein | Ash | Fat | Crude fibre | CHO |

| S2UB | 7.44 ± 0.02a | 22.68 ± 0.01d | 3.54 ± 0.05c | 3.85 ± 0.00b | 0.34 ± 0.00d | 62.20 ± 0.01b |

| S2DB | 10.15 ± 0.05a | 18.55 ± 0.01b | 3.01 ± 0.01b | 7.34 ± 0.02c | 0.25 ± 0.01c | 61.72 ± 1.42b |

| U2UB | 10.17 ± 0.03a | 15.47 ± 0.01a | 3.50 ± 0.00c | 3.54 ± 0.01a | 0.19 ± 0.01b | 67.14 ± 0.01c |

| U2DB | 15.16 ± 0.04c | 20.36 ± 0.01c | 2.49 ± 0.01a | 7.60 ± 0.01d | 0.15 ± 0.01a | 54.25 ± 0.01a |

Values are mean of triplicates ± standard deviation. Mean values with different superscripts within the same column are significantly different at 5% level.

Table 3: Proximate Composition of ‘Ekuru’.

Table 3: Proximate Composition of ‘Ekuru’.

The minerals content of ‘Ekuru’ showed significant (p < 0.05) difference as shown in Table 4. The calcium content ranged from 1.66 to 3.88 with sample U2UB having the lowest value. The iron content ranged between 0.93 and 2.86 with sample U2DB with the lowest value. The sodium content ranged between 198.82 and 256.34 with sample S2UB having the lowest value. The potassium content ranged between 1.00 and 864.88 with sample U2DB having the highest value.

| Sample | Ca | Fe | Na | K |

| S2UB | 2.80 ± 0.01c | 1.30 ± 0.02b | 198.82 ± 0.01a | 1.00 ± 0.00a |

| U2DB | 3.88 ± 0.01d | 0.93 ± 0.01a | 205.75 ± 0.01b | 864.88 ± 0.01b |

| U2UB | 1.66 ± 0.01a | 2.57 ± 0.04c | 256.34 ± 0.01d | 1.00 ± 0.00a |

| S2DB | 2.27 ± 0.11b | 2.86 ± 0.01d | 253.36 ± 0.02c | 1.00 ± 0.00a |

Values are mean of triplicates ± standard deviation. Mean values with different superscripts within the same column are significantly different at 5% level.

Table 4: Minerals Composition of ‘Ekuru’.

Table 4: Minerals Composition of ‘Ekuru’.

The result of functional properties of the bambara nut flour samples is shown in Table 5. There were significant (p < 0.05) difference in the functional properties of the flour samples. The bulk density of the samples ranged from 5.00 to 11.50 gbm3 with the sample U2DB, having the lowest bulk density while S2UB had the highest bulk density. The water absorption capacity ranged from 9.50 to 30.50 with sample S2DB having the lowest WAC, while sample U2UB had the highest value. Swelling power of the flours sample ranged between 3.47 and 6.80 with sample U2UB had the lowest swelling power while sample U2DB had the highest swelling power.

| Sample | BD | WAC | SW |

| S2UB | 11.5 ± 2.12b | 24.50 ± 0.71c | 6.67 ± 0.02c |

| U2DB | 5.00 ± 1.41a | 21.00 ± 1.41b | 6.80 ± 0.01d |

| U2UB | 11.00 ± 1.41b | 30.50 ± 0.71d | 3.47 ± 0.02a |

| S2DB | 5.50 ± 2.12a | 9.50 ± 0.71a | 5.61 ± 0.01b |

Values are mean of triplicates ± standard deviation. Mean values with different superscripts within the same column are significantly different at 5% level.

Table 5: Functional Properties of Bambara nut flour.

Table 5: Functional Properties of Bambara nut flour.

Table 6 shows the physicochemical properties of the bambara nut flour. There are significant (p < 0.05) differences in the pH and the TTA of the samples. The pH values of the flour ranged between 5.83 and 6.44 with sample S2UB having the lowest pH value while sample U2UB had the highest pH value. The TTA values ranged from 11.75 to 28.00, with sample U2UB having the lowest titratable acidity value while sample S2UB had the highest titratable acidity value.

| Sample | pH | TTA |

| S2UB | 5.83 ± 0.04a | 28.00 ± 1.41c |

| U2DB | 5.89 ± 0.01b | 22.70 ± 0.28b |

| U2UB | 6.44 ± 0.02c | 11.75 ± 0.35a |

| S2DB | 5.91 ± 0.01b | 22.25 ± 1.06b |

Values are mean of triplicates ± standard deviation. Mean values with different superscripts within the same column are significantly different at 5% level

Table 6: Physico-chemical Properties of ‘Ekuru’.

Table 6: Physico-chemical Properties of ‘Ekuru’.

Table 7 shows the anti-nutritional properties of the ‘Ekuru’ produced with different processing method. There was significant (p < 0.05) difference in the anti-nutritional properties of the sample. The value of Tannin ranged from 0.73 to 2.57, with the sample with process method S2UB having the lowest tannin values while sample with process method U2DB had the highest value. The trypsin inhibitor values of the samples ranged from 0.02 to 0.06 with sample S2DB having the lowest TIU value while U2UB had the highest TIU value. The phytate content of the sample ranged between 0.28 and 0.53 with the sample S2DB having the lowest value while sample U2DB had the highest value.

| Sample | Tanin | Trypsin | Phytate |

| S2UB | 0.73 ± 0.04a | 0.06 ± 0.01c | 0.34 ± 0.08a |

| U2DB | 2.19 ± 0.04c | 0.02 ± 0.00a | 0.53 ± 0.01a |

| U2UB | 1.22 ± 0.03b | 0.04 ± 0.00b | 0.28 ± 0.23a |

| S2DB | 2.57 ± 0.02d | 0.02 ± 0.00a | 0.32 ± 0.02a |

Values are mean of triplicates ± standard deviation. Mean values with different superscripts within the same column are significantly different at 5% level.

Table 7: Anti-Nutritional Properties of ‘Ekuru’.

Table 7: Anti-Nutritional Properties of ‘Ekuru’.

Table 8 shows the sensory evaluation results of the ‘Ekuru’ samples. There was significant (p ≤ 0.05) difference in the sensory properties. Colour ranged from 6.47 to 7.40, with sample 1 having the lowest rating while sample 2 had the highest value. In terms of Aroma the values ranged from 5.93 to 7.00, with sample 1 having the lowest rating and sample 3 having the highest rating. Taste ratings ranged from 5.30 to 7.20, with sample 4 having the lowest value and sample 3 having the highest sample. In terms of texture there are no significant differences in the samples and the values ranged from 6.13 to 6.80 while for overall acceptability the values ranged from 6.20 to 7.37, with sample 4 having the lowest value and sample 3 having the highest value.

| Sample | Colour | Aroma | Taste | Texture | Overall Acceptability |

| S2UB | 6.47 ± 1.28a | 5.93 ± 1.70a | 5.73 ± 1.93ab | 6.13 ± 1.81a | 6.27 ± 1.66a |

| U2DB | 7.40 ± 1.19b | 6.23 ± 1.63ab | 6.60 ± 1.89bc | 6.23 ± 1.70a | 6.53 ± 1.53a |

| U2UB | 7.30 ± 1.62b | 7.00 ± 1.55b | 7.20 ± 1.52c | 6.80 ± 1.79a | 7.37 ± 1.88b |

| S2DB | 6.77 ± 1.48ab | 6.10 ± 1.58a | 5.30 ± 2.02a | 6.43 ± 1.45a | 6.20 ± 1.24a |

Values are mean of triplicates ± standard deviation. Mean values with different superscripts within the same column are significantly different at 5% level.

Table 8 Sensory Rating of ‘Ekuru’.

Table 8 Sensory Rating of ‘Ekuru’.

The texture, taste, appearance and stability of food depend on the amount of water they contain. Knowledge of the moisture content is often used to predict the behavior of food during processing.

From the result in Table 2 it shows that there is increase in the moisture content of the samples with S2UB having the highest value as a result of its processing method. Sample S2UB had highest value of protein content and this may be due to the destruction of certain anti-nutritional factors during germination of the seed resulting in the release of the nutrient and due to the fact that germination alters the seed protein’s structure and provides an increased proportion of the essential amino acid [11]. Sample U2UB was low in fat but high in crude fibre and ash. Dehulling of the beans resulted in a significant reduction in all the nutrient values. From the result in Table 3, there is significant increase in the moisture content of the ‘Ekuru’ samples which led to the concentration in the nutrient values. The lower fibre and ash content implys that the seed coat is comprised of mainly fibre while the protein and fat are concentrated in the cotyledon and this may have caused the low fibre and ash content in sample S2UB and S2DB.

The germination process led to significant increase in the calcium content of all the samples. The sodium and potassium content were significantly (p > 0.05) reduced and this may be as a result of leaching out of the minerals during soaking and dehulling of the bambara groundnut seeds.

Bulk density is a reflection of the load the flour can carry if allowed to rest directly on one another. The bulk density of solid material determines the ease of handling during transportation and processing [15]. The low bulk density of the processes that involve U2DB may be due to loose structure of the starch polymer. The highest value was observed in the sample S2UB and this will make it useful in convalescence and child feeding. Swelling power is the ability of the starch to absorb water such that the starch granules increase in size/diameter [15]. The U2DB bambara nut flour sample had the greatest swelling power value and this may be attributed to the starch content of the sample. The water absorption capacity and the amount of soluble substance present in starchy foods will affect the palatability of the foods in form of porridge and beverages [14].

The pH of non–germinated bambara nut flour sample (6.44 and 5.89) and the TTA of the sample was found to have an inverse relationship. As the pH of the samples decreased in the germinated samples, the TTA was found to increase from 11.75 to 28.00. In the case of germinated samples the pH dropped from 5.91 to 5.83 with corresponding increase in the titrable acidity. The comparison of pH and titratable acidity in the non-sprouted and sprouted samples revealed that the latter had significantly lower pH and higher titratable acidity as compared to unsprouted one. This could be as attributed to the fact that during germination starch is hydrolysed into sugars which is readily utilized by the organisms and converted to lactic acid [17].

Anti-nutrients are natural or synthetic compounds found in a variety of foods especially grains, beans, legumes and nuts that interfere with the absorption of vitamins, minerals and other nutrients. They can even get in the way of the digestive system which is pertinent for proper absorption [18]. Processing methods such as dehulling, milling, cooking, soaking, germination, fermentation, roasting and frying have been found to reduce/eliminate these anti- nutritional factors which agrees with the result of this obtained in this study. Dehulling and germination process significantly (p < 0.05) reduced the trypsin inhibitor, tannins and phytate content in the Bambara nut flour. The S2UB sample had the lowest tannin content. These reductions will bring about improvement in nutritional quality of the flour sample. Sample S2DB had the lowest value of phytate. The reduction was to the dehulling process indicating that the seed coat contains significant amount of the anti-nutrients. [16] reported that soaking of legumes followed by germination for about 72 hrs will significantly reduce their anti- nutritional factors.

There was significant difference in the colour of the ‘Ekuru’ with the sample S2UB having the lowest values, while sample U2DB had the highest value. This could be as a result of the process of germination because there was a significant change in the colour of the seed after germination and also the removal of the seed coat had a great effect on the colour of the ‘Ekuru’. The taste of the ‘Ekuru’ was affected by the germination process as the sample S2UB had the lowest value and this may be due to the bitter taste observed in it. Nevertheless, despite the low mean scores, the samples were not rejected. The texture was not seriously affected as there was no significant difference in the results obtained while for the overall acceptability of the ‘Ekuru’, sample U2UB had the highest rating and was rated as the most acceptable.

Conclusion

This study was carried out to produce ‘Ekuru’ from bambara groundnut flour produced using different processing methods. The results showed that the germination and dehulling process had a great effect on the proximate, mineral, anti-nutritional contents and functional properties of the ‘Ekuru’ samples.

The sensory acceptability of the ‘Ekuru’ showed that U2UB sample was the most acceptable in terms of taste, aroma and colour. Bambara nut flour using different processing method was successfully employed in the production of acceptable ‘Ekuru’.

References

- Adedokun SO., et al. “Effects of red sorghum stalk extract on chemical composition, acceptability and shelf life of “Ekuru””. Wudpecker Journal of Food Technology 2 (2014): 001-006.

- Amarteifio JO., et al. “The chemical Composition of Four Legumes consumed in Botswana”. Journal of Food Composition and Analysis 11.4 (1998): 329-332.

- “AOAC Association of Official Analytical Chemists Official methods of Analysis of AOAC International, Gaithersburg, MD. USA”. (2000):

- Atiku AN., et al. “Performance Evaluation of a Bambara Ground Nut Sheller”. Agricultural Engineering International: the CIGR Journal of Scientific Research and DevelopmentVI (2004):

- Echendu CA., et al. “Changes in chemical composition of treated and untreated hungry rice acha (Digitaria exilis)”. Pakistan Journal of Nutrition 8 (2009): 1779-1785.

- Heuzé V., et al. “Bambara groundnut (Vigna subterranea) seeds. Feedipedia, a programme by INRA, CIRAD” (2016).

- Ihekoronye AI., et al. “Integrated Food Science and Technology for the tropics”. Macmillan Published London and Basingstoke (1985):

- Maga JA. “Phytates: its chemistry, occurrence, food interactions, nutritional significance and methods of analysis”. Journal of Agriculture and Food Chemistry 3.1 (1982): 1-7.

- Makkar AOS., et al. “Qualification of Tannins. A laboratory manual. International center for Agric Research in the dry areas”. (ICARDA), Aleppo, Syria. (1996): 1v+25.

- Minka SR., et al. “Partial chemical composition of bambara pea (Vigna subterranean (L. Verde)”. Food Chemistry 68.3 (2000): 273-276.

- Neg AP., et al. “Starch and protein digestibility of newly released moth bean cultivans: Effect of soaking, germination and pressure cooking”. Die Nahrung 45.4 (2001): 251-254.

- Ogundele GF., et al. “Proximate composition and organoleptic evaluation of cowpea and soybean blends for the production of moi-moi and ekuru”. Journal of Experimental Biotechnology and Agricultural Sciences 3.2 (2015): 207-222.

- Oluwatofunmi EG., et al. “Formulation and nutritional evaluation of maize, bambara groundnut and cowpea seeds blends complementary food”. American Journal of Food and Nutrition 3.4 (2015): 101-105.

- Ruales, J., et al. “Effect of processing on the physicochemical characteristics of quinoa flour (Chemopodium quiona wild)”. Starch46.10 (1993): 13-19.

- Shittu TA., et al. “Dry milling characteristics of dried cassava chip to moisture content”. Journal of Applied and Technology 2 (2002): 13-18.

- Srilakshin B. “Food Science, 3rd Ed. New age International Publisher Ltd. Town, India”. (2005): 29-35.

- Sudesh J., et al. “Effect of germination and probiotic fermentation on pH, titratable acidity, dietary firbe, b–Glucan and vitamin content of sorghum based food mixture”. Journal of Nutrition and Food Science 2 (2012): 164.

- Wanasundera JP., et al. “Nutritional assessment of yam, tubers”. Plant Foods for Human Nutrition 46.1 (1994): 33-39.

Citation:

Olaleye Hannah., et al. “Effect of Processing Methods on the Acceptability of “Ekuru” Produced from Bambara Groundnut”.

Innovative Techniques in Agriculture 2.4 (2018): 419-427.

Copyright: © 2018 Olaleye Hannah., et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.