Research Article

Volume 1 Issue 6 - 2017

Designing and Characterization of Different Multigrain Breads Prepared from Combination of Composite Flours

Department of Biotechnology, Smt. K.W. College, Sangli 416416, India

*Corresponding Author: Dr. Jai S. Ghosh, Department of Biotechnology, Smt. K.W. College, Sangli 416416. MS. India.

Received: September 05, 2017; Published: September 16, 2017

Abstract

Bread was known to be a staple food right from the dawn of agriculture. It is one of the oldest and largest consumed food stuff across the globe by all age groups. However, it was made from wheat endosperm flour only leavened by the yeast-Saccharomyces cerevisiae and baked suitably. With passage of time, increasing industrialization, increasing number of mouths to feed and with very little time to cook elaborate meals, there was a need for different types of breads needing the use of composite flours of other grains which would provide the consumers the grain nutrients to bridge the gap of malnutrition, especially the protein energy gap and yet is mild to the digestive system. This investigation is aimed to design suitable bread using composite flours of soybean, pearl millet, Sorghum, chick pea, peanuts etc., for middle class citizens. The sample 3 (consisting of 20:50:50:40:40) is one such suitable bread which not only meets the sensory qualities but to a large extent, the nutritional requirements too.

Keywords: Sorghum; soybean; Peanut; Wheat; Pearl millet; Chick pea

Introduction

Bread may be described as a fermented confectionery product which is produced mainly from wheat flour, yeast, water, sugar, salt and other ingredients needed accordingly, by a series of process involving mixing, kneading, proofing, shaping, baking (Dewettnick., et al. 2008).

It has been popular around the world may be since 30,000 years and is one of the oldest artificial foods, having been of importance since the dawn of agriculture (Mace 2017). The most common bread is the white bread made from flour of endosperm of the wheat grain. This flour is free from bran and the germ of the grain. The nutritional value of bread is influenced not only by food interaction but also by consumer perception (Dewettnick., et al. 2008). Due to the high cost, geographical scarcity and high demand of wheat flour, strong initiatives are taken toward the provision of alternative source of flour. It is therefore of economic advantage if wheat import can be reduced by substitution with other nutrient dense materials. This led to the whole idea of composite flour (Oyeku., et al. 2008). The flour contains two important types of protein in high levels, viz. gluteninin and gliadin and the pockets of carbon dioxide produced during the process of leavening gives the dough sponginess and elasticity because of these proteins (McGee, 2004).

There are many combinations and properties of types of flour and other ingredients and also different traditional recipes and modes of preparations of bread, resulting in wide varieties of types, shapes, sizes and texture of breads in various regions (Nwanekazi, 2013). Nutritionally bread is known as ample source for the grains category of nutrition (Ministry of health, 2003). It is good source of carbohydrates, minerals such as magnesium, iron, selenium, along with B vitamins, and dietary fiber (Banu., et al. 2012). However, it never provides proteins in sufficient quantity along with lipids and other nutrients like fat soluble vitamins etc (Cakmak., et al. 2016). There is a new trend in the market to develop a product that combines the health benefits with good sensory properties.

Therefore, other food items, along with bread, like eggs, milk, vegetables etc., are essential to get the missing nutrients. Soy flour added to the composite flour mix helps to increase the protein content (Giami., et al. 2004; Sanful and Darko, 2010). Many food technologists even tried using groundnut in flour blends for bread preparation (Alozie., et al. 2009). In certain African countries attempts were made to prepare composite flour using plantains and soybeans (Olaoye., et al. 2006). Malik., et al. (2015) made an attempt to optimize different parameters for processing of multigrain bread. Previously a similar attempt was also made byIhsan., et al. (2003).

In modern times, due to high work pressure on available time to cook such meals, the most common deficiency is the protein-energy gap. During the day, the time to be provided for lunch is reducing sharply and there is just enough time to have some fast food or quick-bites to get the necessary nutrients for the body. In the evening, the body is so tired at times that rest is more essential than food. In order to overcome such problems of malnutrition, it was thought that the bread be supplemented with all these nutrients in the form of grain nutrients and the concept of multigrain bread was evolved. Such multigrain bread was developed during the late 1980s (Perkin, 1994) and is being sold in many developed nations using the most common 7 grain flours viz. wheat, whole wheat, flax seed, millet and oat flours. Sometime pumpkin seed and/or sunflower seed flours are also used and it becomes composite 9 grain flour. Rye is preferably not used in such types of bread. It is best suited for making sour bread. This type of bread prepared from composite flours has been studied byIndrani., et al. (2010). Composite flour has been defined as a combination of wheat and non-wheat flours for the production of leavened breads, other baked products, and pastas; or wholly non-wheat flour prepared from mixtures of flours from cereals, roots, tubers, legumes, or other raw materials, to be used for traditional or novel products (Dendy1992).

In certain developing countries like those of the Indian peninsula, such situations are growing where due to globalization; there is very high work pressure and very little time for having elaborate meals. Therefore, time has come to develop such types of food like multigrain bread which would to some extent (if not fully) compensate for the nutrient deficiencies. Long time back white bread has become a common food for the people of these regions along with roasted items like flat bread made from whole wheat flour. The main problem of making these multigrain bread with grains as mentioned before, is the cost of the bread. In order to reduce the cost and make these breads affordable, studies are being made to prepare such breads with flours of grains available in the local markets. Since bread is an important food that is generally accepted, they could be an excellent and convenient food item for protein and other nutrient dense fruit seed fortification to improve the nutritional well-being/health of the people which will enhance reduction in protein malnutrition that is prevalent in developing countries. The present study was to produce multigrain breads and evaluate the nutritional values.

Material and Methods

Materials

The following flours of different grains were procured from local market, sorghum, pearl millet, chick pea, and wheat endosperm, defatted cake of peanuts and defatted cakes of soybeans obtained from edible oil industries. Needless to point out that the defatted cakes were ground to flour as their flours were not available in the market.

The following flours of different grains were procured from local market, sorghum, pearl millet, chick pea, and wheat endosperm, defatted cake of peanuts and defatted cakes of soybeans obtained from edible oil industries. Needless to point out that the defatted cakes were ground to flour as their flours were not available in the market.

Compressed yeast was used for all the studies which was obtained from suppliers to bakeries.Other materials needed for making the breads were salt, shortenings etc., were all procured from local market in Sangli. Chemicals required for carrying out different analysis were from reliable indigenous suppliers and were mostly of analytical grade.

Preparation of Composite flours for bread preparation

The oven was set to 220°C and the moulds were allowed to bake for 40 to 45 min., till a pin inserted in it would come out clean.

The oven was set to 220°C and the moulds were allowed to bake for 40 to 45 min., till a pin inserted in it would come out clean.

| Sample No. | Wheat endosperm flour (g) | Pearl millet flour (g) | Sorghum flour (g) | Chick Pea flour (g) | Defatted soybean flour (g) | Defatted Peanut flour (g) |

| 1 | 400 | - | - | - | - | - |

| 2 | 200 | 40 | 40 | 40 | 40 | 40 |

| 3 | 200 | 20 | 50 | 50 | 40 | 40 |

| 4 | 200 | 20 | 40 | 40 | 40 | 60 |

| 5 | 200 | 40 | 20 | 40 | 40 | 60 |

| 6 | 200 | 30 | 40 | 50 | 20 | 60 |

| 7 | 200 | 50 | 40 | 50 | 40 | 20 |

Table 1: Combinations of flours from different grains.

The breads were cooled to room temperature and then either cut or sliced for further analysis.

Chemical analysis of bread samples

Proximate composition

The moisture, crude protein, crude fibre, ash, fat and carbohydrate of the bread samples and 100% wheat bread (control) were determined using standard analytical method. The moisture, crude protein, crude fibre, fat and ash were determined by using AOAC (2000).

Proximate composition

The moisture, crude protein, crude fibre, ash, fat and carbohydrate of the bread samples and 100% wheat bread (control) were determined using standard analytical method. The moisture, crude protein, crude fibre, fat and ash were determined by using AOAC (2000).

Total Carbohydrate

Determination of total carbohydrate was done using the phenol-sulfuric acid method as described by (DuBois., et al. 1956). The total concentration of Carbohydrate obtained from bread samples was Total carbohydrate (%) = (carbohydrate content from calibration curve/weight of sample) x 100

Total phenolic content of the extract were estimated

Determination of total carbohydrate was done using the phenol-sulfuric acid method as described by (DuBois., et al. 1956). The total concentration of Carbohydrate obtained from bread samples was Total carbohydrate (%) = (carbohydrate content from calibration curve/weight of sample) x 100

Total phenolic content of the extract were estimated

Calorimetrically by Folin-Ciocalteu (FC) method (Malik and Singh, 2015). The absorbance of the standard (gallic acid) and the respective extracts was measured spectrophotometrically at 650 nm.

The results were expressed as gallic acid equivalents (GAE, mg/ml of extract).

Water absorption capacity of multigrain composite mixes was determined according to the method of Anderson., et al. (1982). A filter paper was placed in the funnel fitted to the stand, 10 ml of distilled water was added to it with the help of pipette, till the entire paper becomes compressed. The excess water was collected in the beakers. The difference in volume was the water absorbed by the filter paper which was converted into weight (b)

Dry bread sample (10g) (w) was placed in a similar filter paper which is fitted inside a funnel. A definite volume of water was taken in a measuring cylinder and converted in weight (a) and poured drop by drop on the bread so that the entire bread becomes compressed. The excess water was collected in the beaker and its volume was measured and converted in terms of weight(c). The water holding capacity of bread sample was calculated as.

Water absorption capacity = d/w

Where d = a-(b+c)

Where d = a-(b+c)

Swelling index of bread samples

This is determined as the ratio of volume of bread sample to the volume of bread samples after having absorbed maximum water. This is important as it reflects on the amylose to amylopectin ratio in the composite flour.

This is determined as the ratio of volume of bread sample to the volume of bread samples after having absorbed maximum water. This is important as it reflects on the amylose to amylopectin ratio in the composite flour.

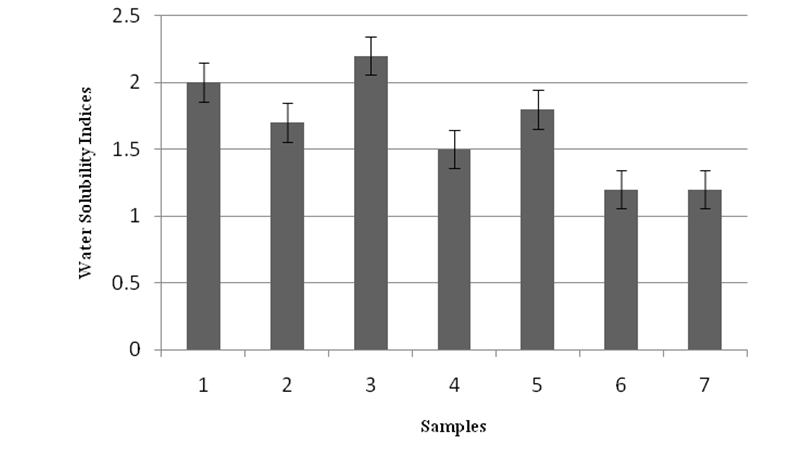

Water solubility index (WSI)

Water solubility index of these mixes was determined from the amount of dried solids recovered by the supernatant from the multigrain composite mixes according to the method of Anderson., et al. (1969). Dry bread sample (10g) was stirred vigorously in 100 ml distilled water. This was then filtered through a reweighed filter paper. The filter paper containing the bread residue was dried and weighed. The difference in weight of the bread sample is due to some parts being dissolved in water and this is the water-soluble fraction of the bread sample. The water solubility index of different types of bread was calculated as. Water solubility index = weight of water soluble fraction/weight of bread sample

Water solubility index of these mixes was determined from the amount of dried solids recovered by the supernatant from the multigrain composite mixes according to the method of Anderson., et al. (1969). Dry bread sample (10g) was stirred vigorously in 100 ml distilled water. This was then filtered through a reweighed filter paper. The filter paper containing the bread residue was dried and weighed. The difference in weight of the bread sample is due to some parts being dissolved in water and this is the water-soluble fraction of the bread sample. The water solubility index of different types of bread was calculated as. Water solubility index = weight of water soluble fraction/weight of bread sample

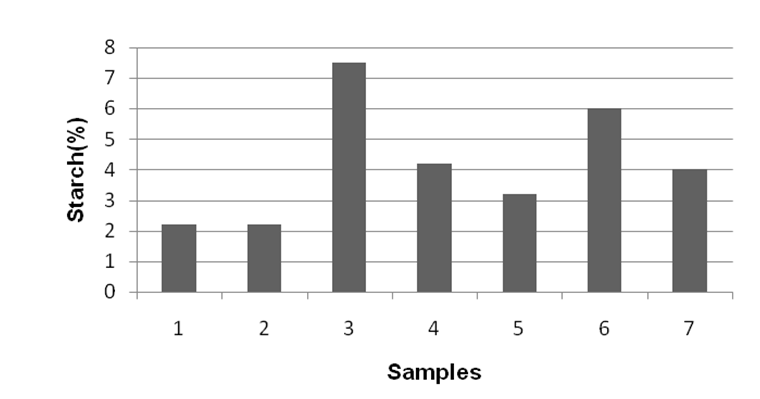

In-vitro starch digestibility

This was estimated according to the method described by Ngo Som., et al. (1992). In the starch digestibility test bread sample was treated with dilute HCl. To this 1 ml 1% Iodine solution was added and the maximum absorbance was recorded at 739 nm. The total concentration of starch was obtained from bread sample after comparing with starch calibration curve.

This was estimated according to the method described by Ngo Som., et al. (1992). In the starch digestibility test bread sample was treated with dilute HCl. To this 1 ml 1% Iodine solution was added and the maximum absorbance was recorded at 739 nm. The total concentration of starch was obtained from bread sample after comparing with starch calibration curve.

Sensory evaluation of the final product

Sensory evaluation with a jury of 5 experts in Food Science and the scores were given on a Hayden scale of 0 to 9

Sensory evaluation with a jury of 5 experts in Food Science and the scores were given on a Hayden scale of 0 to 9

Statistical analysis

Data was analyzed by one-way analysis of variance (ANOVA) with Tukey-Kramer multiple comparison test. In all cases the studies were carried out in triplicate (minimum) or 5 times (maximum) and the p value was always less than 0.5.

Data was analyzed by one-way analysis of variance (ANOVA) with Tukey-Kramer multiple comparison test. In all cases the studies were carried out in triplicate (minimum) or 5 times (maximum) and the p value was always less than 0.5.

Results and Discussion

Functional properties of standard and composite flours

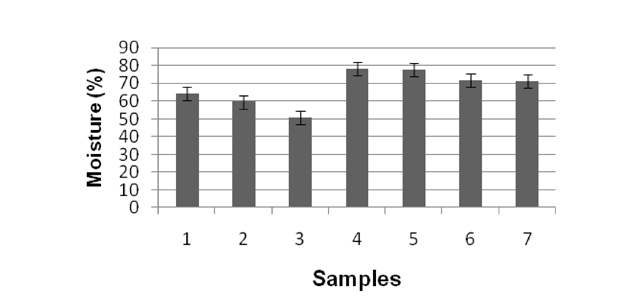

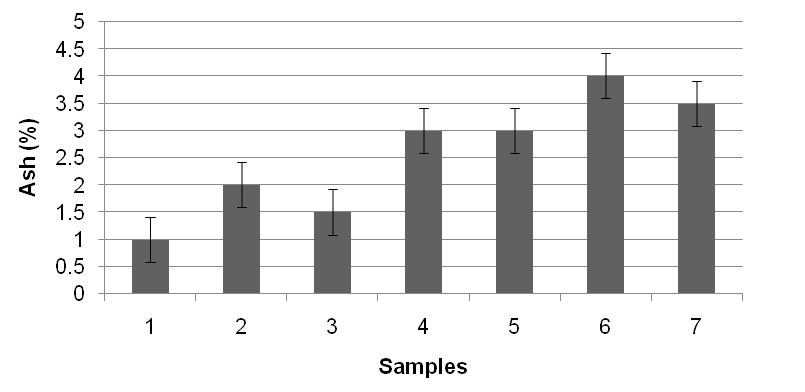

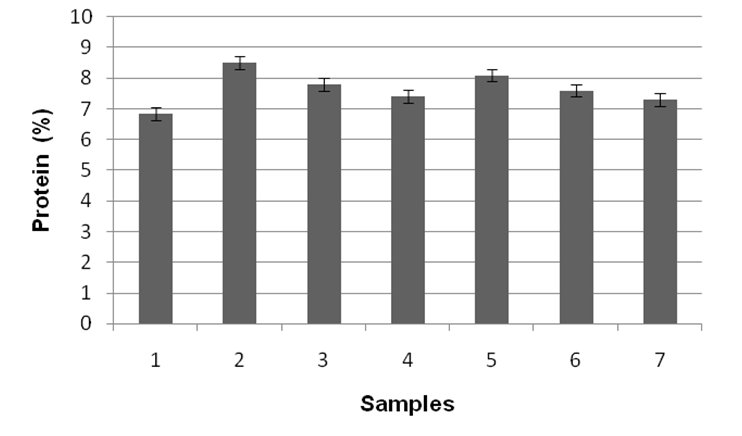

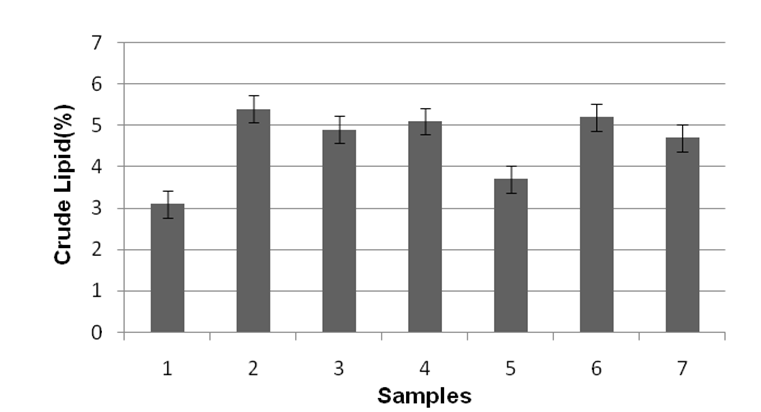

It should be noted that sample 1 in all the figures is the bread prepared from bleached and refined endosperm wheat flour and is used as control for comparison unless stated otherwise.

It should be noted that sample 1 in all the figures is the bread prepared from bleached and refined endosperm wheat flour and is used as control for comparison unless stated otherwise.

It can be noted from Figure 1, that of all the 7 types of bread prepared, sample 4 and 5 has the highest moisture content of nearly 80%. Sample No.3, has the lowest moisture content of 50%. This is as compared to sample 1 which normal white bread and is having 62% moisture. Sample 2 has a moisture content of 60%.

It can be seen from Figure 2, that sample 6 and 7 has the highest ash content (4% and 3.5% respectively). Bread prepared from 100% endosperm wheat flour (Sample 1) had ash content of 1% only. This followed by sample 3 having ash content of 1.5% only.

It is to be noted from Figure 3, that all the 7 types of bread prepared, sample 2 and sample 5 has the highest protein content about 8.5% & 8.1%. However, sample 3 has a protein content of 7.8%. Lower protein content was observed in sample 1 which is nearly 6.8%.

It can be observed from Figure 4 that, from all the 7 type of bread sample prepared, maximum lipid content was observed in sample 2, which is about 5.4%. The lowest lipid content was observed in sample 1, which is nearly about 3.1%.

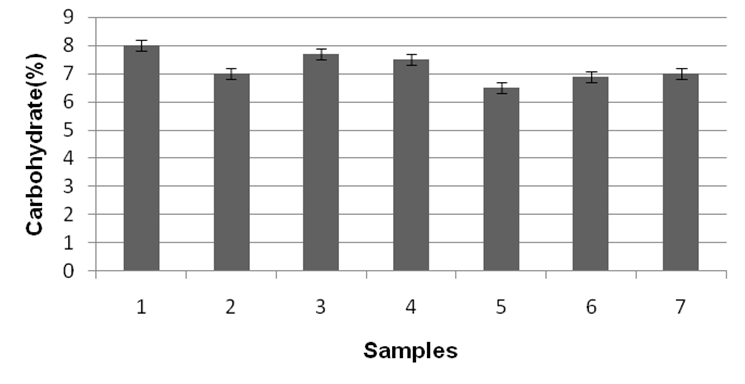

It was noted from Figure 5 that, bread prepared from 100% endosperm wheat flour shows highest carbohydrate content which 8%. The lowest carbohydrate content in sample 5 was 6.5%. The carbohydrate content of sample 3 was 7.7%.

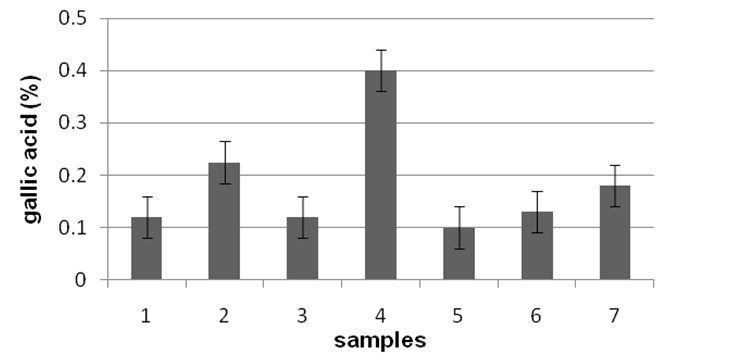

It is evident from Figure 6, that from all the 7 type of bread sample prepared, maximum gallic acid content was observed in sample 4, which is around 0.40%, followed by sample 2 and 7. Lowest gallic acid content was observed in sample 5 i.e. 0.10%. However, sample 1 and 3 had gallic acid content of 0.12%.

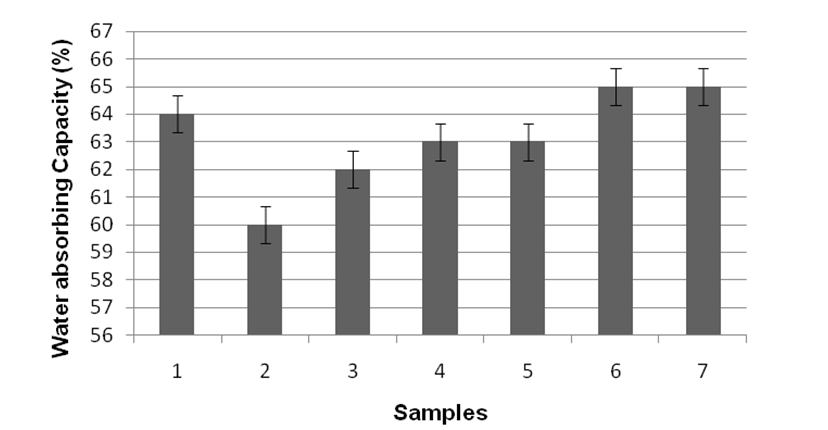

It is evident from Figure 7, that from all the 7 types of bread prepared, sample 6 and 7 show highest water absorbing capacity which is nearly about 65%. Sample 4 and 5 showed similar water absorbing capacity which is nearly about 63%. Sample 2 has the lowest water absorbing capacity of about 60%. Sample 3 has water absorbing capacity of 62% as compared to sample 1 i.e. bread from only wheat endosperm flour, which has water absorbing capacity of 64%.

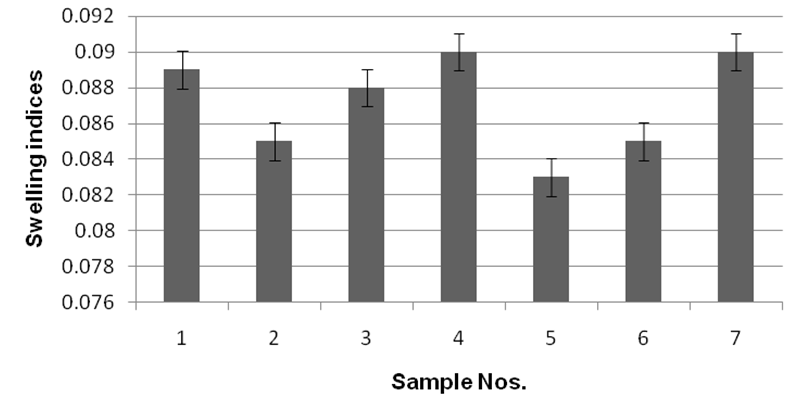

It can be seen from Figure 8, that highest swelling indices observed for samples 4 and 7 was 0.09 each. Sample 1 which was purely made from endosperm flour of wheat had a swelling index of 0.089 while sample 3 had a swelling index of 0.088. Sample 5 had the least swelling index of 0.083.

It was seen from Figure 9 that, from all the 7 type of bread sample prepared, sample 3 shows highest water solubility index which is 2.2. Sample 6 and sample 7 shows lowest water solubility index of about 1.2, Water solubility index of sample 1 is 2.

It can be observed from Figure 10 that indigestible starch 2.1% was in sample 1 (bread from flour of endosperm of wheat) and that of sample 2. The highest indigestible starch was detected in sample 3 where it was more than 7%.

| Parameters | Scores given by the members of jury on samples (2 to 7) | |||||

| 2 | 3 | 4 | 5 | 6 | 7 | |

| Outside appearance | 8 | 8 | 8 | 8 | 8 | 8 |

| Color of slices | 6 | 7 | 7 | 6 | 7 | 7 |

| Odor | 8 | 8 | 8 | 8 | 8 | 8 |

| Flavor | 5 | 9 | 8 | 7 | 8 | 8 |

| Consistency | 7 | 9 | 7 | 7 | 7 | 7 |

| Mouth fullness | 8 | 9 | 7 | 7 | 7 | 7 |

Table 2: Organoleptic properties of standard and experimental breads.

It can be noted that sample 3, was fairly accepted by the panel of jury to be suitable for consumers not only on the nutritional values but also on the basis of sensory analysis.

Conclusion

Finally it must be stressed that the consumer must get the required nutrition from a good balanced diet prepared at home. The grain nutrition received from such processed food will not provide the entire required daily intake. The multigrain bread is only a stop gap arrangement to avoid nutritional deficiencies through malnutrition. It is and will never be a substitute for a good cooked wholesome meal prepared at home.

Acknowledgement

The authors are very grateful to the authorities of Smt. K.W. College, Sangli 416416, India and their Department of Biotechnology for extending all laboratory support for successful completion of the project.

The authors are very grateful to the authorities of Smt. K.W. College, Sangli 416416, India and their Department of Biotechnology for extending all laboratory support for successful completion of the project.

References

- Alozie EY., et al. “Utilization of bambara groundnut flour blends in bread production”. Journal of Food Technology 7.4 (2009):111-114.

- Anderson RA., “Water absorption and soplubility and amylograph charachteristic of roll- cooked small grain products”. Cereal Chemistry 59 (1982): 265-269.

- AOAC Official Method of Analysis, 17th Ed., Association of Official Analytical Chemists International. Gaithersburg, Maryland, USA (2000).

- Banu H., et al. “Preparation, nutritional composition, functional properties and antioxidant activities of multigrain composite mixes”. Journal of Food Science Technology 49.1 (2012): 74-81.

- Cakmak H., et al. “Production of crispy bread snacks containing chicken meat and chicken meat powder”. Anais da Academia Brasileira de Ciências 88.4 (2016): 2387-2399.

- Dendy DV. Composite flour - past, present and the future: a review with special emphasis on the place of composite flour in the semiarid zones. In M I Gomez, L R House, LW Rooney, & DV Dendy (Eds.), Utilization of sorghum and millets, ICRISTAT, (1992):67-73.

- Decompressedtnick K., et al. “Nutritional value of bread: influence of processing, food interactions and consumer perception”. Journal of Cereal Sciences 48.2 (2008): 243-247.

- DuBois M., et al. “Colorimetric method for determination of sugars and related substances”. Analytical Chemistry 28.3 (1956): 350-356.

- Giami SY., et al. “Comparison of bread making properties of composite flour from kernels of roasted and boiled African breadfruit (Treculia Africana decne) seeds”. Journal of Raw Material Research 1 (2004): 16-25.

- Ihsan MQ., et al. “Effect of different fermentation time & baking on phytic acid content of whole flour bread”. Asian Journal of Plant Sciences 2 (2003): 597-601.

- Indrani D., et al. “Multigrain bread–its dough rheology, microstructure, quality and nutritional characteristics”. Journal of Texture Studies41.3 (2010): 302-319.

- Mace J. “The history of a mouthful of bread and its effect”. Translated by Gatty A, (8th English French edition) Harper. New York 2017).

- Malik CP. and Singh MB. “Estimation of Polyphenols”, International Journal Advanced Research in Biological Sciences 2 (2015): 185-189.

- Malik H Nayak AG. “Optimization of process for development of nutritionally enriched multigrain bread”, Journal of Food Process Technology7 (2015): 544-550.

- McGee H. Food and cooking (4th edition) (2004), the Guardian, London.

- Ministry of Health Food and nutrition guidelines for healthy adults a background paper, Ministry of Health. Adult Nutrition Survey. Wellington, New Zealand (2003).

- Ngo Som J., et al. “Digestibility of protein and starch in malted weaning foods” Journal of Food Science and Technology 29.4 (1992): 262-263.

- Nwanekazi EC. “Composite flours for baked products and possible challenges – a review”. Nigerian Food Journal 31.2 (2013): 8-17.

- Oyeku OM., et al. “An economic assessment of commercial production of 10%Cassava – wheat composite flour bread”. Journal of Industrial Research and Technology 2.1 (2008): 13-20.

- Olaoye OA., et al. “Quality characteristics of bread produced from composite of wheat, plantain and soybeans”. African Journal of Biotechnology 5.11 (2006): 1102-1106.

- Perkin J. Food processing, Tech press (FPI) limited, US (1994).

- Plummer DT. “Introduction to practical Biochemistry, (3rd edition. 33rd reprint) (2008), Tata McGraw Hill publication, Mumbai. India.

- Sanful ER and Darko S. “Utilization of soybean flour in the production of bread”. Pakistan Journal of Nutrition 9.8 (2010): 815-818.

Citation:

Jai Ghosh., et al. “Designing and Characterization of Different Multigrain Breads Prepared from Combination of Composite

Flours”. Nutrition and Food Toxicology 1.6 (2017): 205-215.

Copyright: © 2017 Jai Ghosh., et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.