Research Article

Volume 2 Issue 5 - 2018

Methodology to Optimize Blend Ratio of Barley and Finger Millets for Production of Beer

1&4Department of Food Technology, Uttaranchal University, Dehradun-248007

2&3Department of Post Harvest Process and Food Engineering, G. B. Pant University of Agriculture and Technology, Pantnagar-263145, U S Nagar, Uttarakhand, (India)

2&3Department of Post Harvest Process and Food Engineering, G. B. Pant University of Agriculture and Technology, Pantnagar-263145, U S Nagar, Uttarakhand, (India)

*Corresponding Author: Khan Chand, Department of Post-Harvest Process and Food Engineering, G. B. Pant University of Agriculture and Technology, Pantnagar-263145, U S Nagar, Uttarakhand, India.

Received: February 10, 2018; Published: February 28, 2018

Abstract

Investigations were conducted in three steps (malting, brewing and fermentation) to produce beer from barley, finger millet and the combination of both. Effects of independent variables with three levels for each i.e. blend ratios of grains (100:0, 50:50, 0:100), kilning temperature (50°C, 70°C, 90°C) and malted grain to water ratios (1:3, 1:5, 1:7) were find out on beer quality. The results of this study indicated that all the independent parameters i.e. blend ratio, kilning temperature and slurry ratio affected the responses (pH, bitterness and alcohol content) significantly. Optimum values of independent variables, from the simultaneous optimization done using Design Expert 8.0.6.1 software, for beer production, were found to be 79:21 blend ratios, 50°C kilning temperature and 1:7 slurry ratios. Out of three independent variables (blend ratio, kilning temperature and slurry ratio) considered during the study blend ratio has the maximum effect on alcohol content while the slurry ratio and kilning temperature affect the bitterness of the beer. The model F-value was found to be highly significant at 1% level of significance for all the responses.

Keywords: Beer; Blend ratio; Alcohol content; Bitterness; Finger millet and Barley

Introduction

There are many crops including cereals and legumes which are locally cultivated in Uttarakhand in large quantity. Underutilized crops are the lesser known species in terms of trade and research, and often adapted to marginal and stress conditions Joshi., et al. (2002). With ample of nutritional benefits, these are very much accepted as part of staple diet and also have the potential to be converted or included in processed foods. In spite of the advantages associated with their production and nutritive value, these lesser known crops have received very little attention in terms of research.

Finger millet is one of the major underutilized crops of Uttarakhand. The overall production of finger millet in Uttarakhand is 170484quintal. It ranks sixth in production after wheat, rice, maize, sorghum and bajra in India. Finger millet has gained importance because of its nutritional quality in terms of dietary fiber, functional fiber, starch pattern as well as high calcium and iron contents (Balkrishna., et al. 1973; Deosthale., et al. 1970). Maltingcharacteristics of finger millet are superior to other millets and ranks next to barley malt (Malleshi and Desikachar, 1986; Pawar and Dhanvijay, 2007).

Malting of finger millet improves its digestibility, sensory and nutritional quality as well as has pronounced effect in lowering the ant nutrients. Barley is the primary cereal used in the production of malt in the world (Broderick 1977). Barley is the basic raw material for brewing. It’s chemical composition, brewing, and technological indices are highly determinative for the beer quality and the economic efficiency of the brewing process. Barley is rich in protein, carbohydrates, dietary fibers, minerals, and vitamins Mahesh., et al. (2010).

The use of Indian finger millet in brewing has been investigated by Venkatanarayana., et al. (1979). It has potentially useful characteristics with respect to brewing Taylor., et al. (2006). The major brewing products are alcoholic/non-alcoholic beverages made from barley, maize flour, malted millet etc. Malt is mostly prepared from barley grains but other cereals and starch containing substances are also used now days. These include corn, rice, wheat, sorghum, sweet sorghum, cassava, etc. The brewing industry is constantly looking for ways to improve beer quality and reduce manufacturing costs. Finger millet, which grows well in tropical countries and containing good amount of reducing sugars, can become a substitute for barley in beer production. Hence, finger millet could be a good alternative for barley as a brewing source.

Fermentation technology is found to be beneficial in manufacturing of alcoholic beverages like beer, wine etc. Alcoholic beverages i.e. Kodo KoJaanr, Madua, Themsing, Rakshi, Mingri, Lohpani, Bhangchang and Tella (local name of respective regions) of finger millet made by fermentation technology. Presently, Barley is mainly used for production of beer. The combination of 50% ragi and 50% barley malt is found to be ideal and hence could be used for preparation of beverages Venkatanarayana., et al. (1979). Research and improvement efforts are needed to explore the potential of finger millet to increase agricultural production. As there is a clear indication that product development and value addition to these crops using established technologies can increase their utilization and improve incomes to small scale farmers/small entrepreneurs. An attempt has been made to explore the underutilized crops utilization (finger millet and barley) using fermentation technology.

Material and Methods

The present study has been planned to develop a fermented beverage (beer) using under exploited crops (finger millet and barley) of the State. Experiments were carried out in the department of Post Harvest Process and Food Engineering to study the process parameters and to standardize a process for development of beer using barley and finger millet. Independent variables and their ranges were finalized on the basis of preliminary trial results and review of literature.

Raw materials used in the studies

The raw grains i.e. Finger millet (Eleusinecoracana), Barley (Hordeumvulgare) oftraditional varieties, required for the study, were purchased from the local market ofHaldwani and Ramnagar District Nainital. Grains were cleaned manually and kept in moisture proof plasticcontainers for studies.Hops, the female flower clusters (commonly called seed cones or strobiles), of a hopspecies, Humuluslupulus were procured from M/s Manavbreweries Ghaziabad (UP) and used primarily as a flavoring and stability agent in beer, as they impart a bitter,tangy flavor.Yeast strains (Saccharomyces cerevisiae MTCC 170).

The raw grains i.e. Finger millet (Eleusinecoracana), Barley (Hordeumvulgare) oftraditional varieties, required for the study, were purchased from the local market ofHaldwani and Ramnagar District Nainital. Grains were cleaned manually and kept in moisture proof plasticcontainers for studies.Hops, the female flower clusters (commonly called seed cones or strobiles), of a hopspecies, Humuluslupulus were procured from M/s Manavbreweries Ghaziabad (UP) and used primarily as a flavoring and stability agent in beer, as they impart a bitter,tangy flavor.Yeast strains (Saccharomyces cerevisiae MTCC 170).

Preliminary experiments

Preliminary experiments were conducted to identify the various affecting the fermentation process of beer production from barley and finger millet and to select the process variables and their experimental range for the study. Variables considered on the basis of review were blend ratios: Barley: Finger millet X1 (100:0, 50:50, 0:100), kilning temperature for production of malt was desirable for maintaining the quality of beer. The minimum temperature for kilning has been reported as 50°C for finger millet (Karki and Kharel 2012) and maximum temperature has been reported as 90°C. Hence, it was desired that the kilning temperature range for production of malt from finger millet and barley should be kept X2 (50, 70, 90°C), the malted grains and water ratio range was kept in the range of 1:2, 1:4, 1:6 and preliminary trails were conducted and it was observed during the experiment that the ratio 1:2 was not good as quality of wort, it was not appropriate because complete water got evaporated so wort could not be prepared. Hence, the ratios were changed to X3 (1:3, 1:5, and 1:7). The design of 17 experiments were done using Design Expert 8.0.6.1 software (Box Behenken method) (Khuri and Cornell 1987) shown in Table 1.

Preliminary experiments were conducted to identify the various affecting the fermentation process of beer production from barley and finger millet and to select the process variables and their experimental range for the study. Variables considered on the basis of review were blend ratios: Barley: Finger millet X1 (100:0, 50:50, 0:100), kilning temperature for production of malt was desirable for maintaining the quality of beer. The minimum temperature for kilning has been reported as 50°C for finger millet (Karki and Kharel 2012) and maximum temperature has been reported as 90°C. Hence, it was desired that the kilning temperature range for production of malt from finger millet and barley should be kept X2 (50, 70, 90°C), the malted grains and water ratio range was kept in the range of 1:2, 1:4, 1:6 and preliminary trails were conducted and it was observed during the experiment that the ratio 1:2 was not good as quality of wort, it was not appropriate because complete water got evaporated so wort could not be prepared. Hence, the ratios were changed to X3 (1:3, 1:5, and 1:7). The design of 17 experiments were done using Design Expert 8.0.6.1 software (Box Behenken method) (Khuri and Cornell 1987) shown in Table 1.

| Expt. No. | Coded values | Actual values | ||||

| X1 | X2 | X3 | Blend ratio barley: finger millet |

Kilning temperature (°C) | Slurry ratio (malted grain: water) |

|

| 1 | -1 | -1 | 0 | 100:0 | 50 | 1:5 |

| 2 | 1 | -1 | 0 | 0:100 | 50 | 1:5 |

| 3 | -1 | 1 | 0 | 100:0 | 90 | 1:5 |

| 4 | 1 | 1 | 0 | 0:100 | 90 | 1:5 |

| 5 | -1 | 0 | -1 | 100:0 | 70 | 1:3 |

| 6 | 1 | 0 | -1 | 0:100 | 70 | 1:3 |

| 7 | -1 | 0 | 1 | 100:0 | 70 | 1:7 |

| 8 | 1 | 0 | 1 | 0:100 | 70 | 1:7 |

| 9 | 0 | -1 | -1 | 50:50 | 50 | 1:3 |

| 10 | 0 | 1 | -1 | 50:50 | 90 | 1:3 |

| 11 | 0 | -1 | 1 | 50:50 | 50 | 1:7 |

| 12 | 0 | 1 | 1 | 50:50 | 90 | 1:7 |

| 13 | 0 | 0 | 0 | 50:50 | 70 | 1:5 |

| 14 | 0 | 0 | 0 | 50:50 | 70 | 1:5 |

| 15 | 0 | 0 | 0 | 50:50 | 70 | 1:5 |

| 16 | 0 | 0 | 0 | 50:50 | 70 | 1:5 |

| 17 | 0 | 0 | 0 | 50:50 | 70 | 1:5 |

Table 1: Experimental Design.

Experimental procedure

Steeping

Barley and finger millet were cleaned and washed thoroughly to remove immature grains, light materials, dirt and were steeped in surplus water at room temperature (28 ± 2°C) for a period of 24 hrs. The water was changed every 6 to 8 hours over a period of 24 hrs.

Steeping

Barley and finger millet were cleaned and washed thoroughly to remove immature grains, light materials, dirt and were steeped in surplus water at room temperature (28 ± 2°C) for a period of 24 hrs. The water was changed every 6 to 8 hours over a period of 24 hrs.

Germination

After soaking, for a period of 24 hrs, the water was drained off and the grains were left on stainless steel sieves for germination process for a period of 30-36 hrs. Grains were gently disturbed in order to provide aeration and to prevent from matting. During preliminary experiments, the germination was done for a period of 48 hrs but during that period mould growth was observed. The germination was observed to be best in period of 30-36 hrs.

After soaking, for a period of 24 hrs, the water was drained off and the grains were left on stainless steel sieves for germination process for a period of 30-36 hrs. Grains were gently disturbed in order to provide aeration and to prevent from matting. During preliminary experiments, the germination was done for a period of 48 hrs but during that period mould growth was observed. The germination was observed to be best in period of 30-36 hrs.

Kilning

After germination, the germinated grains (green malt) were kilned in Integrated Malting Unit at different temperature (50, 70, 90°C) for 14-20 hrs. Kilning was done till the desired moisture content was achieved (3-5% for barley and 9 ± 1% for finger millet) as reported by Karki and Kharel (2012).

After germination, the germinated grains (green malt) were kilned in Integrated Malting Unit at different temperature (50, 70, 90°C) for 14-20 hrs. Kilning was done till the desired moisture content was achieved (3-5% for barley and 9 ± 1% for finger millet) as reported by Karki and Kharel (2012).

Brewing process for beer

Milling

The malt was crushed manuallyand breaks down barriers in the grains, giving the enzymes, full access to the carbohydrates, present in the grains, and facilitates the efficient extraction of the soluble material (extract) from the malt. This malt is called ‘malt grist’.

Milling

The malt was crushed manuallyand breaks down barriers in the grains, giving the enzymes, full access to the carbohydrates, present in the grains, and facilitates the efficient extraction of the soluble material (extract) from the malt. This malt is called ‘malt grist’.

Mashing

To prepare the wort, malted grain and water (1:3, 1:5, 1:7 slurry ratios) was boiled. Firstly, only the water as per the ratio maintained (210, 350, 490ml) was heated at the temperature 68-70°C respectively and after heating, the malted grain as per the ratio (100:0, 50:50, 0:100) kept (70gm of barley/500ml, 35gm barley+35gm finger millet/500ml and 70 gm of finger millet/500ml) were added and the total mixture was again boiled for 40 min at slow fire.

To prepare the wort, malted grain and water (1:3, 1:5, 1:7 slurry ratios) was boiled. Firstly, only the water as per the ratio maintained (210, 350, 490ml) was heated at the temperature 68-70°C respectively and after heating, the malted grain as per the ratio (100:0, 50:50, 0:100) kept (70gm of barley/500ml, 35gm barley+35gm finger millet/500ml and 70 gm of finger millet/500ml) were added and the total mixture was again boiled for 40 min at slow fire.

Wort separation

500 ml of tap water was heated at 68-70°C in another ware and sparging was done with hot water. The mash was repeatedly washed (2-3 times) so that maximum extract can be obtained. This was done with the help of strainer. This clear liquid obtained through this process is called wort.

500 ml of tap water was heated at 68-70°C in another ware and sparging was done with hot water. The mash was repeatedly washed (2-3 times) so that maximum extract can be obtained. This was done with the help of strainer. This clear liquid obtained through this process is called wort.

Wort boiling and hopping

As soon as the wort started boiling, 1 gm (in 500 ml of wort) of hops were added to enhance the flavor and colour of the final product and the whole mixture was kept on boiling at 100°C for further 1 hr at slow fire.

As soon as the wort started boiling, 1 gm (in 500 ml of wort) of hops were added to enhance the flavor and colour of the final product and the whole mixture was kept on boiling at 100°C for further 1 hr at slow fire.

Hops separation and wort cooling

After 1 hrs boiling, hops were separated by using strainer and muslin cloth. After hops separation, the wort was cooled at a temperature of 18-20°C which was best for yeast growth in fermentation.

After 1 hrs boiling, hops were separated by using strainer and muslin cloth. After hops separation, the wort was cooled at a temperature of 18-20°C which was best for yeast growth in fermentation.

Fermentation of wort

When the wort was cooled at the temperature of 18-20°C, the level of wort was less than 500 ml, hence the volume was made up to 500ml by adding simple tap water and then 30 ml of liquid yeast was transferred in 500ml wort in Laminar flow chamber. After transferring the yeast, the flask was closed with cotton plug and placed in dark place. After three days, cotton plug was removed and flasks were again plugged using fermentation lock for a period of 14 days.

When the wort was cooled at the temperature of 18-20°C, the level of wort was less than 500 ml, hence the volume was made up to 500ml by adding simple tap water and then 30 ml of liquid yeast was transferred in 500ml wort in Laminar flow chamber. After transferring the yeast, the flask was closed with cotton plug and placed in dark place. After three days, cotton plug was removed and flasks were again plugged using fermentation lock for a period of 14 days.

Yeast separation

After 14 days of fermentation, fermented liquor was centrifuged at 4000-5000 rpm for 15 minutes in order to remove all yeast cells, Supernatants was stored in refrigerator at low temperature.

After 14 days of fermentation, fermented liquor was centrifuged at 4000-5000 rpm for 15 minutes in order to remove all yeast cells, Supernatants was stored in refrigerator at low temperature.

Analysis of responses

pH of fermented liquor

The pH of sample was measured directly by digital pH meter (Triode India). The pH probe was calibrated using standard buffer solution (pH 4 and pH 7) prior to measurement of pH of sample at 30°C.

pH of fermented liquor

The pH of sample was measured directly by digital pH meter (Triode India). The pH probe was calibrated using standard buffer solution (pH 4 and pH 7) prior to measurement of pH of sample at 30°C.

Bitterness of fermented liquor

Ten milliliters of fermented liquor was taken in a 35 mL centrifugal tube and degassed with the help of magnetic stirrer by stirring gently. Wavelength was kept 275 nm and absorbance was set 0.000 with 2, 2, 4-trimethyl pentane as a reference blank. Twenty milliliter 2, 2, 4-trimethyl pentane and 0.5 mL HCL (6 mol/L) was taken in centrifuge tube and rotated for 15 min in centrifuge. The centrifugation was done until maximum extraction had been achieved. The absorbance of the sample was recorded for centrifuged sample and this was repeatedly done till no change in absorbance was observed. Bitterness was calculated by the formula given below:

BU = A275 × 50

Where, A is absorbance at 275 nm in a 10 mm cuvette.

Ten milliliters of fermented liquor was taken in a 35 mL centrifugal tube and degassed with the help of magnetic stirrer by stirring gently. Wavelength was kept 275 nm and absorbance was set 0.000 with 2, 2, 4-trimethyl pentane as a reference blank. Twenty milliliter 2, 2, 4-trimethyl pentane and 0.5 mL HCL (6 mol/L) was taken in centrifuge tube and rotated for 15 min in centrifuge. The centrifugation was done until maximum extraction had been achieved. The absorbance of the sample was recorded for centrifuged sample and this was repeatedly done till no change in absorbance was observed. Bitterness was calculated by the formula given below:

BU = A275 × 50

Where, A is absorbance at 275 nm in a 10 mm cuvette.

Ethanol estimation

Alcohol was estimated calorimetrically according to Reid and Salmon, (1955). A standard curve was prepared by using 0.0 to 8.0 mg/ml of absolute alcohol to which 2 ml standardize (0.36 N) ceric ammonium nitrate reagent was added. After 5 min of mixing, the extinction was read at 486 nm on spectrophotometer. A blank was also prepared using 5 ml of distilled water. Calibration curve was plotted taking ethanol concentration on x-axis and absorbance on y-axis.

Alcohol was estimated calorimetrically according to Reid and Salmon, (1955). A standard curve was prepared by using 0.0 to 8.0 mg/ml of absolute alcohol to which 2 ml standardize (0.36 N) ceric ammonium nitrate reagent was added. After 5 min of mixing, the extinction was read at 486 nm on spectrophotometer. A blank was also prepared using 5 ml of distilled water. Calibration curve was plotted taking ethanol concentration on x-axis and absorbance on y-axis.

Samples (5 ml) collected after distillation in graduated tube were further diluted five times in order to get color in the range of standard curve. 5 ml of the diluted distillate was taken and 2 ml of ceric ammonium nitrate was added; after 5 min. extinction was determined by computing the absorbance against a standard curve of absolute alcohol.The regression analysis of the responses was conducted by fitting to the suitable model represented by the following equation:

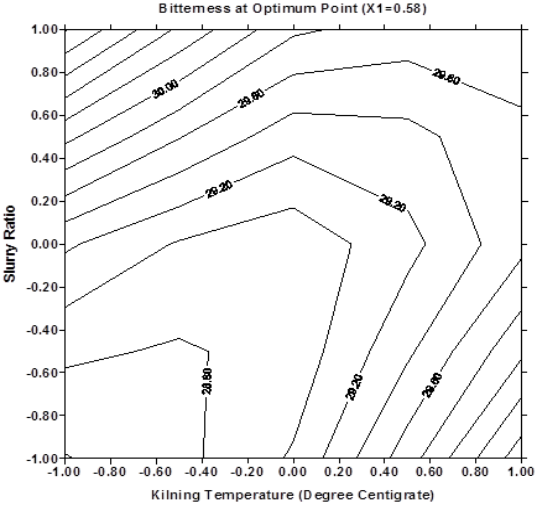

Where, Y is the response; k is the number of independent variables, Xi (i = 1, 2, 3, 4, 5) is the input predictor or controlling variable: β0 is the constant coefficient, βi, βij, and βii are the coefficients of linear, interaction and quadratic term, respectively.

Results and Discussion

The experiments were planned using Response Surface Methodology (Khuri and Cornell, 1987) with Box Behenken Design for three variables. A full second order mathematical model was fitted into each response. The adequacy of the model was tested using coefficient of determination (R2) and Fisher’s F-test. The model was used to interpret the effects of variables namely blend ratio, kilning temperature and slurry ratio on responses viz. pH, bitterness and alcohol content. If the model was found adequate, the best fit equations were developed in order to draw contour plots for showing the effect of independent variables on the responses and to select the range of variables for an acceptable product. Optimization of various process conditions was done using software Design-Expert 8.0.6.1. The data from all the seventeen experiments were analyzed and the response functions were developed using multiple regression. Analysis of variance was used to analyze the models.

Effect of independent variables on pH

Out of all process parameters, pH is one of the important parameter that determines the quality of beer. pH and buffering capacity of mash can influence the flavour stability. The experimental data as tabulated in Table 2 shows the pH levels of beer for different combination of the experiments conducted. Maintaining the correct pH for enzyme during the mash ensure the proper conversion of starch and degradation of haze causing protein. Data in the Table 2 shows that the least pH (5.05) of beer was observed in Experiment No. 8 which had blend ratio 0:100 (X1 = 1), kilning temperature 70°C (X2 = 0), and 1:7 slurry ratio (X3 = 1). The maximum pH (5.63) was observed for the Experiment No. 7 which had blend ratio 100:0 (X1 = -1), kilning temperature 70°C (X2 = 0), and 1:7 slurry ratio (X3 = 1).These data shows that the pH was maintained throughout the entire range of experiments i.e. ranging from 5.05 to 5.63 which shows an acceptable range as brewer’s normally look for a pH of 5.2 to 5.5.

Out of all process parameters, pH is one of the important parameter that determines the quality of beer. pH and buffering capacity of mash can influence the flavour stability. The experimental data as tabulated in Table 2 shows the pH levels of beer for different combination of the experiments conducted. Maintaining the correct pH for enzyme during the mash ensure the proper conversion of starch and degradation of haze causing protein. Data in the Table 2 shows that the least pH (5.05) of beer was observed in Experiment No. 8 which had blend ratio 0:100 (X1 = 1), kilning temperature 70°C (X2 = 0), and 1:7 slurry ratio (X3 = 1). The maximum pH (5.63) was observed for the Experiment No. 7 which had blend ratio 100:0 (X1 = -1), kilning temperature 70°C (X2 = 0), and 1:7 slurry ratio (X3 = 1).These data shows that the pH was maintained throughout the entire range of experiments i.e. ranging from 5.05 to 5.63 which shows an acceptable range as brewer’s normally look for a pH of 5.2 to 5.5.

| Exp. No. | Blend ratio | Kilning temperature | Slurry ratio | pH | Bitterness | Alcohol content |

| 1 | 100:0 | 50 | 1:5 | 5.4 | 29.50 | 8.08 |

| 2 | 0:100 | 50 | 1:5 | 5.21 | 29.0 | 6.22 |

| 3 | 100:0 | 90 | 1:5 | 5.6 | 30.05 | 6.75 |

| 4 | 0:100 | 90 | 1:5 | 5.3 | 29.8 | 7.07 |

| 5 | 100:0 | 70 | 1:3 | 5.18 | 29.4 | 12.08** |

| 6 | 0:100 | 70 | 1:3 | 5.45 | 29.3 | 9.66 |

| 7 | 100:0 | 70 | 1:7 | 5.63** | 30.5 | 4.17* |

| 8 | 0:100 | 70 | 1:7 | 5.05* | 29.35 | 8.60 |

| 9 | 50:50 | 50 | 1:3 | 5.24 | 28.50* | 9.70 |

| 10 | 50:50 | 90 | 1:3 | 5.52 | 30.50 | 8.2 |

| 11 | 50:50 | 50 | 1:7 | 5.15 | 32.50** | 7.5 |

| 12 | 50:50 | 90 | 1:7 | 5.29 | 30.50 | 5.8 |

| 13 | 50:50 | 70 | 1:5 | 5.50 | 29.50 | 4.6 |

| 14 | 50:50 | 70 | 1:5 | 5.45 | 29.50 | 4.8 |

| 15 | 50:50 | 70 | 1:5 | 5.51 | 29.6 | 5.5 |

| 16 | 50:50 | 70 | 1:5 | 5.55 | 28.5* | 4.2 |

| 17 | 50:50 | 70 | 1:5 | 5.42 | 28.6 | 4.4 |

| *Minimum and **Maximum | ||||||

Table 2: Data for beer production from barley and finger millet.

Full second order model, Eqn 1 was fitted to the data of pH and experimental conditions using regression analysis to estimate the response of dependent variables and results are given in Table 3. The coefficient of determination (R2) of the regression model for pH was 92.77%, which implies that the model could account for 92.77% of data and 7.23% variation is not explained by the model. The R2 value for the response variable was higher than 0.90 showing that the regression model explained the reaction well. Lack of fit was insignificant; therefore, second order model was adequate in describing pH. The predictive equation is given below.

pH = 5.48600-0.100X1+ 0.088750X2 - 0.033750X3- 0.027500X1X2 - 0.21250X1X3 - 0.035X2X3- 0.040500X12 -0.068X22 - 0.11800X32 .....................2

pH = 5.48600-0.100X1+ 0.088750X2 - 0.033750X3- 0.027500X1X2 - 0.21250X1X3 - 0.035X2X3- 0.040500X12 -0.068X22 - 0.11800X32 .....................2

| pH | Bitterness | Alcohol | ||||

| Coeff. | P value | Coeff. | P value | Coeff. | P value | |

| Cons | 5.49 | 0.0031 | 29.14 | .041 | 4.7 | 0.0029 |

| X1 | -0.100 | 0.0047*** | -0.25 | .2706 | 0.059 | 0.8613 |

| X2 | 0.089 | 0.0086*** | 0.17 | .4460 | -0.46 | 0.1989 |

| X3 | -0.034 | 0.2119 | 0.64 | .0178** | -1.70 | 0.0012*** |

| X1X2 | -0.028 | 0.4546 | 0.062 | .8386 | 0.54 | 0.2734 |

| X1X3 | -0.21 | 0.0005*** | -0.26 | .4040 | 1.71 | 0.0073*** |

| X2X3 | -0.035 | 0.3473 | -1.0 | .0117** | -0.050 | 0.9162 |

| X12 | -0.041 | 0.2706 | -0.21 | .4947 | 1.58 | 0.0096*** |

| X22 | -0.068 | 0.0846 | 0.65 | .0572 | 0.75 | 0.1367 |

| X32 | -0.12 | 0.0102** | 0.71 | .0443 | 2.35 | 0.0012*** |

| R2 (%) | 92.77% | 83.66% | 92.91% | |||

Table 3: Results of regression analysis of quality parameters for beer.

Where, X1, X2 and X3 are coded variables for blend ratios, kilning temperature, and slurry ratios respectively. Total effect of individual parameters on pH given in Table 4. It was observed that blending ratios (X1), slurry ratios (X3) affected the pH at 1% level of significance and Kilning temp (X2) affected the pH at 5% level of significance. The ANOVA conducted for pH has an adequate precision; a measure of signal to noise ratio (11.2728) indicates a better precision and reliability of the experiment carried out. A ratio greater than 4 is desirable. Hence, in the present study the ratio of 11.2728 indicates an adequate signal to use the model for prediction purposes.

| Source | DF | SS | MS | F-value |

| Model | 9 | 0.43 | 0.048 | 9.98*** |

| Blending ratios(X1) | 4 | 0.2699 | 0.0674 | 14.04*** |

| Kilning temp(X2) | 4 | 0.08992 | 0.02248 | 4.68** |

| Slurry ratios(X3) | 4 | 0.2530 | 0.06325 | 13.17*** |

| Error | 7 | 0.034 | 0.0048 | |

| Total | 16 | 0.64682 |

***, **, *Significant at 1, 5 and 10% level of significance respectively.

Table 4: Total effect of individual parameters on pH.

Table 4: Total effect of individual parameters on pH.

Effect of independent variables on bitterness

Bitterness of the beer was measured over entire range of experiment 1-17. The Table 2 shows that the bitterness of beer varied from 28.50 to 32.50. As per Beer Style International Bittering Unit, ASBC, the acceptable range for bitterness of ale type of beer is reported to be 12 to 40. The values of bitterness come in acceptable range for various set of experiments. The bitterness of beer is due to addition of hops. The least bitterness value (28.5) of beer was observed for Experiment No. 9, 16 having blend ratio 50:50 (X1 = 0), kilning temperature 50°C (X2 = -1), and 1:3 slurry ratio (X3 = -1) and blend ratio 50:50 (X1 = 0), kilning temperature 70°C (X2 = 0), and 1:5 slurry ratio (X3 = 0) respectively. The maximum bitterness value (32.5) was observed for the Experiment No. 11 which had blend ratio 50:50 (X1 = 0), kilning temperature 50°C (X2 = -1), and 1:7 slurry ratio (X3 = -1). It could be seen from Table 2 that highest value of bitterness was obtained for experiment no. 11 where the pH for the same experiment is quite low. The reason behind the increase in bitterness could perhaps due to the fact that lower pH slightly decreases hop utilization and therefore, improves the quality of the bitterness, while higher pH slightly increases hop utilization and the harness of bittering compounds. The hop utilization is temperature dependent and could affect the bitterness of the beer. The coefficient of determination (R2) of the regression model for bitterness was 83.66%, which implies that the model could account for 83.66% of data. The predictive equation for estimating bitterness is given below

Bitterness = 29.1400-0.2500X1+ 0.16875X2+0.64375X3+0.062500X1X2-0.26250X1X3- 1.0X2X3- 0.20750X12 +0.6550X22 + 0.70500X32 ..........................3.

Bitterness of the beer was measured over entire range of experiment 1-17. The Table 2 shows that the bitterness of beer varied from 28.50 to 32.50. As per Beer Style International Bittering Unit, ASBC, the acceptable range for bitterness of ale type of beer is reported to be 12 to 40. The values of bitterness come in acceptable range for various set of experiments. The bitterness of beer is due to addition of hops. The least bitterness value (28.5) of beer was observed for Experiment No. 9, 16 having blend ratio 50:50 (X1 = 0), kilning temperature 50°C (X2 = -1), and 1:3 slurry ratio (X3 = -1) and blend ratio 50:50 (X1 = 0), kilning temperature 70°C (X2 = 0), and 1:5 slurry ratio (X3 = 0) respectively. The maximum bitterness value (32.5) was observed for the Experiment No. 11 which had blend ratio 50:50 (X1 = 0), kilning temperature 50°C (X2 = -1), and 1:7 slurry ratio (X3 = -1). It could be seen from Table 2 that highest value of bitterness was obtained for experiment no. 11 where the pH for the same experiment is quite low. The reason behind the increase in bitterness could perhaps due to the fact that lower pH slightly decreases hop utilization and therefore, improves the quality of the bitterness, while higher pH slightly increases hop utilization and the harness of bittering compounds. The hop utilization is temperature dependent and could affect the bitterness of the beer. The coefficient of determination (R2) of the regression model for bitterness was 83.66%, which implies that the model could account for 83.66% of data. The predictive equation for estimating bitterness is given below

Bitterness = 29.1400-0.2500X1+ 0.16875X2+0.64375X3+0.062500X1X2-0.26250X1X3- 1.0X2X3- 0.20750X12 +0.6550X22 + 0.70500X32 ..........................3.

The total effect of individual parameter on bitterness given in Table 5. It was observed that kilning temp (X2) and slurry ratios (X3) affected the bitterness at 5% level of significance. Lack of fit was insignificant; therefore second order model was found to be adequate in describing bitterness.

| Source | DF | SS | MS | F-value |

| Model | 9 | 12.52 | 1.39 | 3.98** |

| Blending ratios (X1) | 4 | 0.976 | 0.244 | 0.697 |

| Kilning temp (X2) | 4 | 6.056 | 1.514 | 4.325** |

| Slurry ratios (X3) | 4 | 9.69 | 2.42 | 6.91** |

| Error | 7 | 2.45 | 0.35 | |

| Total | 16 | 19.172 | 4.528 |

Table 5: Total effect of individual parameters on Bitterness.

Effect of independent variables on Alcohol content

The Table 2 shows that the % alcohol varies from 4.17 to 12.08 indicating the presence of alcohol. The least alcohol content (4.17) of beer was observed in Experiment No. 07 which have blend ratio 100:0 (X1 = -1), kilning temperature 70°C (X2 = 0), and 1:7slurry ratio (X3 = 1) in the experiment. The maximum alcohol content (12.08) was observed for the Experiment No. 5 which had blend ratio 100:0 (X1 = -1), kilning temperature 70°C (X2 = 0), and 1:3 slurry ratio (X3 = -1). The maximum alcohol content 12.08% was observed for blend ratio (100:0) which shows that the barley alone could produce alcohol but the presence of alcohol as 9.70% also proves that if the finger millet is mixed with barley (50:50), the alcohol could be produced to some extent. Hence, full potential of important but underutilize source of starch, the finger millet could be explored for production of beer. The coefficient of determination (R2) of the regression model for alcohol content was 92.91%, which implies that the model could account for 92.91% of data and 7.09% variation was not explained by the model. Lack of fit was insignificant; therefore, second order model was adequate in describing alcohol content. The predictive equation is given below

Alcohol = 4.700+0.058750X1-0.46000X2-1.69625X3+0.54500X1X2+1.71250X1X3-0.050000X2X3+1.57875X12 +0.75125X22 +2.34875X32 ...................4.

The Table 2 shows that the % alcohol varies from 4.17 to 12.08 indicating the presence of alcohol. The least alcohol content (4.17) of beer was observed in Experiment No. 07 which have blend ratio 100:0 (X1 = -1), kilning temperature 70°C (X2 = 0), and 1:7slurry ratio (X3 = 1) in the experiment. The maximum alcohol content (12.08) was observed for the Experiment No. 5 which had blend ratio 100:0 (X1 = -1), kilning temperature 70°C (X2 = 0), and 1:3 slurry ratio (X3 = -1). The maximum alcohol content 12.08% was observed for blend ratio (100:0) which shows that the barley alone could produce alcohol but the presence of alcohol as 9.70% also proves that if the finger millet is mixed with barley (50:50), the alcohol could be produced to some extent. Hence, full potential of important but underutilize source of starch, the finger millet could be explored for production of beer. The coefficient of determination (R2) of the regression model for alcohol content was 92.91%, which implies that the model could account for 92.91% of data and 7.09% variation was not explained by the model. Lack of fit was insignificant; therefore, second order model was adequate in describing alcohol content. The predictive equation is given below

Alcohol = 4.700+0.058750X1-0.46000X2-1.69625X3+0.54500X1X2+1.71250X1X3-0.050000X2X3+1.57875X12 +0.75125X22 +2.34875X32 ...................4.

The total effect of individual parameter on alcohol content given in Table 6. It was observed that slurry ratio (X3) affects the alcohol at 1% level of significance and blending ratios (X1) and kilning temp (X2) affects the alcohol at 5%, 10% level of significance respectively.

| Source | DF | SS | MS | F-value |

| Model | 9 | 77.11 | 8.57 | 10.19*** |

| Blending ratios(X1) | 4 | 23.438 | 5.8595 | 6.9755** |

| Kilning temp(X2) | 4 | 5.27 | 1.3175 | 1.5684* |

| Slurry ratios(X3) | 4 | 57.99 | 14.4975 | 17.258*** |

| Error | 7 | 5.89 | 0.84 | |

| Total | 16 |

Table 6: Total effect of individual parameters on alcohol.

Optimum values of independent variables for beer production were recommended as blend ratio 0.58 (79), kilning temperature -1 (50°C) and slurry ratio 1 (7).

Graphical interpretation of independent variable on pH

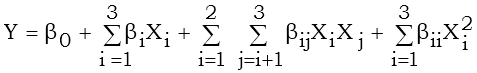

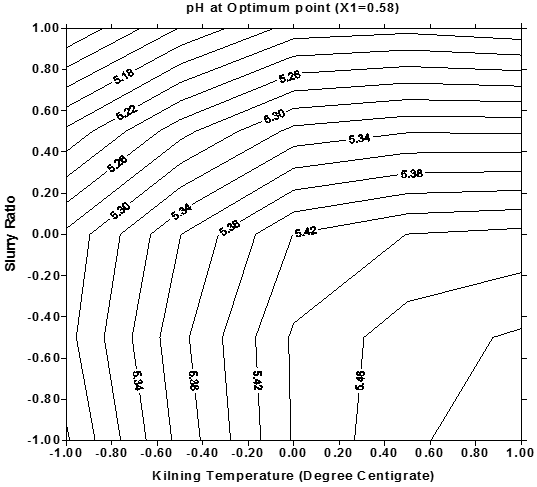

Figure 1 shows the effects of slurry ratio and kilning ratio on pH at optimum points of blend ratio 0.58 (79). It was observed that the pH increases with decreases in slurry ratio while pH increases with increase in kilning temperature to point 0.20. Figure 2 shows the effects of slurry ratio and blend ratio on pH at optimum points of kilning temperature X2 = -1 (50°C). It was observed that the pH decreases with increase in blend ratio and slurry ratio.

Figure 1 shows the effects of slurry ratio and kilning ratio on pH at optimum points of blend ratio 0.58 (79). It was observed that the pH increases with decreases in slurry ratio while pH increases with increase in kilning temperature to point 0.20. Figure 2 shows the effects of slurry ratio and blend ratio on pH at optimum points of kilning temperature X2 = -1 (50°C). It was observed that the pH decreases with increase in blend ratio and slurry ratio.

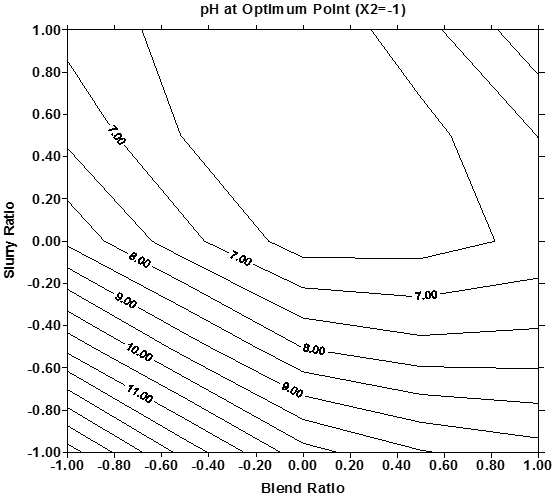

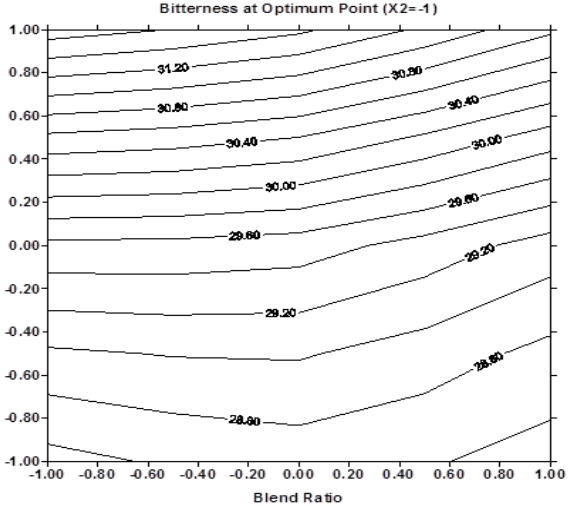

Figure 3 shows the effects of slurry ratio and kilning ratio on bitterness at optimum points of blend ratio 0.58 (79). It was observed that, bitterness increased with increase in kilning temperature and slurry ratio. Figure 4 shows the effects of slurry ratio and blend ratio on bitterness at optimum points of kilning temperature X2 = -1 (50°C). It was predicted that as the slurry ratio increased, the bitterness increased but not so much affected by blend ratio.

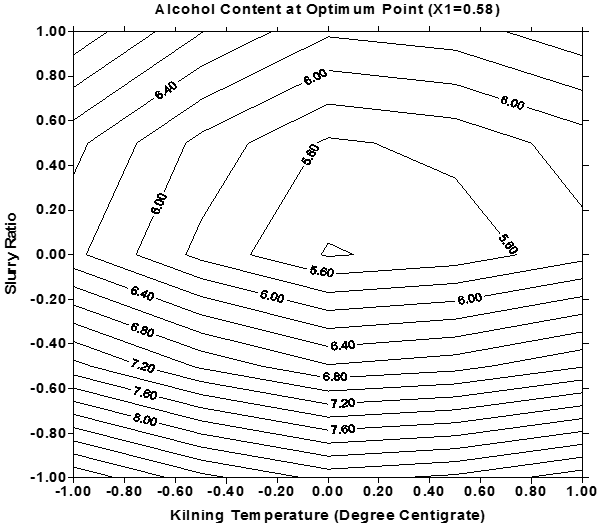

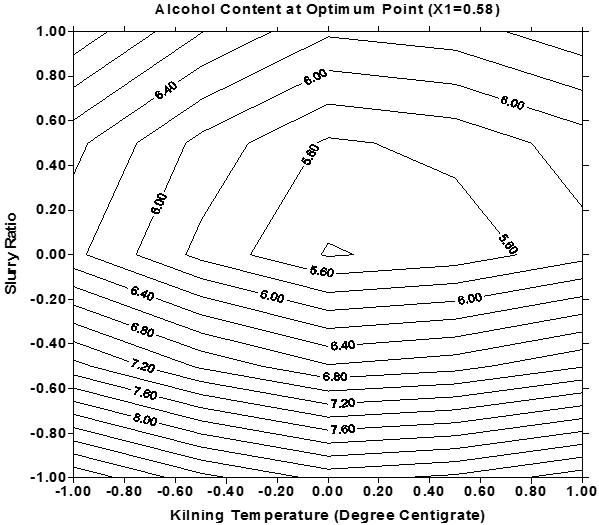

Figure 5 shows the effects of slurry ratio and kilning ratio on bitterness at optimum points of blend ratio 0.58 (79). It was observed that as kilning temperature and slurry ratio increased the alcohol content decreased. Figure 6 shows the effects of slurry ratio and blend ratio on bitterness at optimum points of kilning temperature X2 = -1 (50°C). It was observed that as the blend ratio increased, the alcohol content was found to be decreased and alcohol content was also decreased as slurry ratio increased.

Conclusions

It was concluded that the beer could be produced using finger millet under natural fermenting conditions using Saccharomyces cerevisiae strains as the alcohol production at blend ratio 0:100 which was found to be 9.66% because finger millet is a rich source of carbohydrate beer production is quite valuable.

Acknowledgement

This research was carried out in the Department of Post Harvest Process & Food Engineering under the National Fellow Project funded by the Indian Council of Agriculture Research. We sincerely thank the Research Director and Dean of the College of Technology, G.B.P.U.A. & T., Pantnagar for providing necessary support for the smooth functioning of the research work.

This research was carried out in the Department of Post Harvest Process & Food Engineering under the National Fellow Project funded by the Indian Council of Agriculture Research. We sincerely thank the Research Director and Dean of the College of Technology, G.B.P.U.A. & T., Pantnagar for providing necessary support for the smooth functioning of the research work.

References

- Balkrishna Rao K., et al. “Nutrient content of some new ragi varieties”. Journal of Agricultural Science 7 (1973): 562-565.

- Broderick H. El Cervecero en la Practica: Un Manual para la IndustriaCervecera. 2nd ed. Wisconsin, U.S.A.: Assn. de Maestros Cerveceros de las Americas. (1977): 29-52.

- Deosthale YG., et al. “Nutrient composition of some varieties of ragi”. The Indian Journal of Nutrition and Dietetics 7 (1970): 80.

- Joshi V., et al. “Conservation and Use of Underutilized Crops: An Indian Perspective”. In: Managing Plant Genetic Diversity (JMM. Engels, VR Rao, AHD Brown and MT Jackson (Eds.)). IPGRI. (2002): 61-73.

- Karki DB and Kharel GP. “Effect of finger millet varieties on chemical characteristics of their malts”. African Journal of Food Science6.11 (2012): 308-316.

- Khuri AI and Cornell JA Response surface design and analysis. Marcel Dekker, Inc. ASQC Quality Press, NewYork, (1987): 112-139.

- Mahesh Gupta., et al. “Barley for Brewing: Characteristic Changes during Malting, Brewing and Applications of its By-Products”. Comprehensive reviews in food science and food safety 9.3 (2010): 318-328.

- Malleshi NG and Desikachar HSR. “Influence of malting conditions on quality finger millet”. Journal of the Institute of Brewing 92 (1986): 81-83.

- Pawar PA and Dhanvijay VP. “Weaning foods: An overview”. Beverage Food World 34.11 (2007): 27-33.

- Reid VM and Salmon DG. The determination of ethanol by Colourimetric method. The Analyst 80 (1955): 704.

- Taylor JRN., et al. “Novel food and non-food uses for sorghum and millets”. Journal of Cereal Science 44.3 (2006): 252-271.

- Venkatanarayana S., et al. “The use of Ragi (Eleusinecoracana) in brewing. Journal of Food Science and Technology 16.5 (1979): 204-206.

Citation:

Khan Chand., et al. “Methodology to Optimize Blend Ratio of Barley and Finger Millets for Production of Beer”. Nutrition and

Food Toxicology 2.5 (2018): 439-450.

Copyright: © 2018 Khan Chand., et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.