Research Article

Volume 2 Issue 5 - 2018

Oil Yield and Physiochemical Properties of Balanites aegyptiaca (l.) del. Kernels at Various Process Treatments

Department of Home Science, Faculty of Agriculture, Federal University, Gashua, Nigeria

*Corresponding Author: Ogori AF, Department of Home Science, Faculty of Agriculture, Federal University, Gashua, Nigeria.

Received: April 01, 2018; Published: April 11, 2018

Abstract

The oil yield and physiochemical properties of Balanites aegyptiaca oil were investigated. Balanites fruits were source from different locations within Yobe State, Nigeria. Fruits collected were crushed and the kernel extracted and dried. The kernels were subjected to three (3) different treatments of toasting only, boiling and toasting and soaking overnight at ambient temperature and toasting. Toasted groundnut seeds were used as the fourth treatment and served as the control. The oil from the milled flour was mechanically expelled using centrifugal screw which is semi-automated for oil expelling from entrapped increase surface area. The oil yields from the roasted, boiled and soaked Balanites kernels were 50%, 26% and 21% crude oil yield respectively while the control (groundnut seed oil) had 23%. Physiochemical analysis of the oil samples from the varied process treatments of Balanites kernel revealed the moisture content of 0.05–0.059%, acid value of 4.44mg/KOH/g, saponfication value of 193.54–98.81mg/KOH/g, iodine values of 64–80wijis, peroxide value of 4.40–61.20meq/kg, unsaponifiable matter of 0.0044–0.0070mg/KOH/g, free fatty acid of 1.085– 4.22mgKOH/g, viscosity of 45 – 48.0mpa/s and refractive index of 1.502–1.8 at 360C. The results revealed that Balanites seed when boiled and soaked had better physiochemical properties than groundnut oil, however with low oil yield. This could provide good quality oil to food, pharmaceutical and for bioenergy generation industry.

Keywords: Balanites aegyptiaca; Kernels; Oil yield; Physiochemical properties

Introduction

Majority of consumable food stuff are made of oil derived from seeds or kernels or nuts together with proteins and carbohydrates (Manji., et al. 2013). Oil derived from seeds, kernels and nuts are rich in protein and carbohydrate providing energy in form of fat (Onuekwusi., et al. 2014). Physicochemical characteristics of oil are important determinant of its nutritional quality and commercial value (Omujal, 2008; Chapagain., et al. 2009). For oil to be selected for use either for human or industrial purpose, it has to meet some basic physiochemical criteria.

In Nigeria, groundnuts oil and oil palm are the major source of edible oil used in cooking, manufacture of soap, margarine and cosmetics. However, there is an increase in demand which has necessitated importation of cooking oil from other part of the world. This called for research into indigenous oil-bearing fruit which can be exploited for production of oils, both for consumption and industrial applications. Balanites aegyptiaca generally referred to as desert date, is a multipurpose fruit tree commonly found in the arid environment. It was reported to have diverse application both in the area of nutrition and health (NRC 2008).

Investigation carried out by some researchers on yield and physicochemical properties of B. aegyptiaca oil had revealed the presence of oil which is rich and fatty acids of high stability (Chapagain and Wiesman 2005; Okia 2010;Manji., et al. 2013;Gardette and Baba 2013). oil yield studies conducted on B. aegyptiaca kernel by Manji., et al. (2013) and Okia (2010) revealed the kernel to contain 49.9% of oil and between 40–50% respectively while Chapagain and Wiesman (2005) reported oil yield of 46.12%, 44.17% and 39.20% from Israel, Africa and India respectively. The results from the different authors show variation in oil yield from different location. This implies that location possibly had influenced on yield though the variation might not be significant. Physiochemical investigation on B. aegyptiaca oil from different researchers shows that the oil are of high stability and can compete favourably with vegetable oils like groundnut, palm kernel, castor oils (Okia 2010; Manji., et al. 2013).

Most studies conducted on oil yield and physiochemical analysis on B. aegyptiaca used the standard method of oil extraction, though scientifically accepted but it is expensive and might not be affordable to the rural poor. Even studies that used the machine pressed method of oil extraction or mechanically expelled methods followed the process of seed processing/treatments such as the fruits crushing to obtain kernel–drying– toasting–grinding–addition of water–extraction of oil using machine. It is therefore imperative to conduct more investigation into techniques and processes that could result in better oil yield and better physiochemical properties of oil extracted from the kernel of B. aegyptiaca with the view of recommending affordable, accessible and improved process of processing kernels for oil extraction, this will helps in improving nutrition and income generation of the rural dwellers as well as boast the economy of the nation.

Materials and Methods

Samples collection and preparation

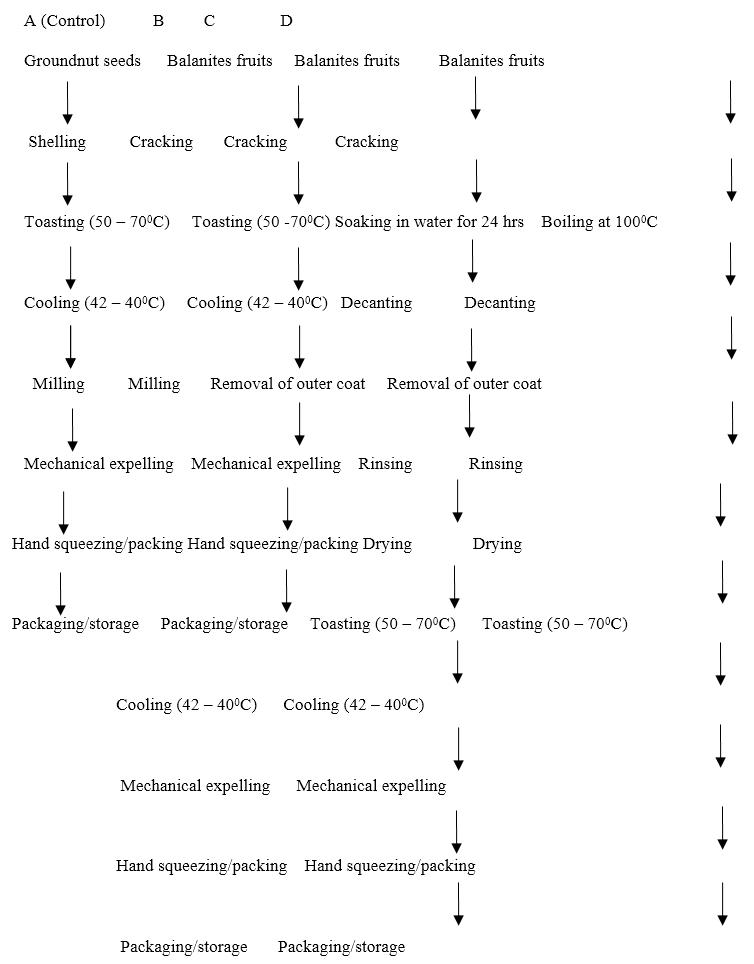

Forty five (45) kg of B. aegyptiaca fruits were collected from the villages around Gashua town and its suburbs. The fruits collected from all these locations were cracked manually to extract the kernels. The kernels were subjected to three (3) different treatments of toasting only before milling and oil extraction, boiling and then toasting before milling and oil extraction and soaking overnight at ambient temperature before toasting and oil extraction. Toasted groundnut seeds were used as the fourth treatment and served as the control. The oil from the milled flour was mechanically expelled using centrifugal screw which is semi-automated for oil expelling from entrapped increase surface area. The flow chart of the treatments process is shown in Figure1.

Forty five (45) kg of B. aegyptiaca fruits were collected from the villages around Gashua town and its suburbs. The fruits collected from all these locations were cracked manually to extract the kernels. The kernels were subjected to three (3) different treatments of toasting only before milling and oil extraction, boiling and then toasting before milling and oil extraction and soaking overnight at ambient temperature before toasting and oil extraction. Toasted groundnut seeds were used as the fourth treatment and served as the control. The oil from the milled flour was mechanically expelled using centrifugal screw which is semi-automated for oil expelling from entrapped increase surface area. The flow chart of the treatments process is shown in Figure1.

Physicochemical Analysis

Physicochemical properties such as, acid value, saponification value, peroxide value, Iodine value, Moisture content, viscosity, free fatty acid, refractive index were determined according to the Association of Official Analytical Chemists (AOAC, 2000)

Physicochemical properties such as, acid value, saponification value, peroxide value, Iodine value, Moisture content, viscosity, free fatty acid, refractive index were determined according to the Association of Official Analytical Chemists (AOAC, 2000)

Results and Discussion

Oil yield (%)

The oil yield from seeds of groundnut which is used as control was 23% while the oil yield of B. aegyptiaca for treatments A, B and C was 50, 26 and 21% respectively (Table 1). Oil yield extracted from B. aegyptiaca kernel toasted only (Sample B) was more than those soaked and boiled kernels before toasting (Sample C and D). This implies that toasting only yielded higher oil in comparison with the other treatments. The oil yield obtained from sample B is similar to that reported by Okia (2010) from samples sourced from Katakwi district in Uganda (50.56%) and Manji et al., (2013) who reported oil yield of 49.09% from samples sources from Adamawa, Nigeria but higher than Chapagain and Wiesman (2005) who reported oil yield of 46.12%, 44.17% and 39.20% from Israel, Africa and India populations of B. aegyptiaca respectively. This indicates that yield obtained from toasted kernel using mechanical expeller results in higher yield than even those extracted from solvent method as reported by chapagain and Wiesman (2005). However, similar yield was reported by Okia (2010) who also used solvent extraction method. This implies that method of extraction alone might not be the only reason for the observed difference. The combined effects of source of the kernel (Variation in environment) and method of extraction could be possible explanation for the difference in yield. The oil yield from the (soaked) sample C and (boiled) sample D was lower than those reported in sunflower (35%), safflower (30%) and olive (30%), but compares well with and soybean (20%), cotton seed (15%) and more than that of corn (3.0 to 6.5%) (Alexander, 2009).

The oil yield from seeds of groundnut which is used as control was 23% while the oil yield of B. aegyptiaca for treatments A, B and C was 50, 26 and 21% respectively (Table 1). Oil yield extracted from B. aegyptiaca kernel toasted only (Sample B) was more than those soaked and boiled kernels before toasting (Sample C and D). This implies that toasting only yielded higher oil in comparison with the other treatments. The oil yield obtained from sample B is similar to that reported by Okia (2010) from samples sourced from Katakwi district in Uganda (50.56%) and Manji et al., (2013) who reported oil yield of 49.09% from samples sources from Adamawa, Nigeria but higher than Chapagain and Wiesman (2005) who reported oil yield of 46.12%, 44.17% and 39.20% from Israel, Africa and India populations of B. aegyptiaca respectively. This indicates that yield obtained from toasted kernel using mechanical expeller results in higher yield than even those extracted from solvent method as reported by chapagain and Wiesman (2005). However, similar yield was reported by Okia (2010) who also used solvent extraction method. This implies that method of extraction alone might not be the only reason for the observed difference. The combined effects of source of the kernel (Variation in environment) and method of extraction could be possible explanation for the difference in yield. The oil yield from the (soaked) sample C and (boiled) sample D was lower than those reported in sunflower (35%), safflower (30%) and olive (30%), but compares well with and soybean (20%), cotton seed (15%) and more than that of corn (3.0 to 6.5%) (Alexander, 2009).

| SAMPLES | A | B | C | D |

| Yields (%) | 23 | 50 | 26 | 21 |

Table 1: Oil yield of Balanite aegyptiaca seed oil at various process treatments

Keys:

Sample A (Groundnut oil) winnowed, roasted seed

Sample B (Balanites oil) Roasted, winnowed seed

Sample C (Balanites oil) Soaked, winnowed, roasted seed

Sample D (Balanites oil) B oiled, winnowed, roasted seed

Sample A (Groundnut oil) winnowed, roasted seed

Sample B (Balanites oil) Roasted, winnowed seed

Sample C (Balanites oil) Soaked, winnowed, roasted seed

Sample D (Balanites oil) B oiled, winnowed, roasted seed

Physiochemical analysis

Table 2 showed physiochemical properties of balanites oil at various process treatments. Moisture content was found to range between 0.05 - 1.54% (Table 2). Sample C, B and D had lower moisture content compare with sample A (control). The moisture content is an indication of the storagebility of material. These values of samples B and C are lower than what was reported by Lohun (2012), Manji., et al. (2013) and Sara (2015). However, sample D has higher moisture contents (0.59 %) than that of Manji., et al. (2013) moisture content of 0.27%. Oil extracted from sample B and C can therefore be regarded to be more stable than the others.

Table 2 showed physiochemical properties of balanites oil at various process treatments. Moisture content was found to range between 0.05 - 1.54% (Table 2). Sample C, B and D had lower moisture content compare with sample A (control). The moisture content is an indication of the storagebility of material. These values of samples B and C are lower than what was reported by Lohun (2012), Manji., et al. (2013) and Sara (2015). However, sample D has higher moisture contents (0.59 %) than that of Manji., et al. (2013) moisture content of 0.27%. Oil extracted from sample B and C can therefore be regarded to be more stable than the others.

Acid value tells of the quality of free fatty acid and extent of lipolytic hydrolysis in oil. Sample A oil had lower acid value of 1.18mgKOH/g compared with sample B, C and D which had acid value of 7.814mgKOH/g, 2.17mgKOH/g and 4.44mgKOH/g respectively. Sample B and D oil had higher acid value (1.53mgKOH/g) in comparison with that reported by Sara (2015) and Okia (2010). However, Sample Coil had similar acid value of 2.08mgKOH/g as reported by Babeker (2013). This indicates that control (sample A) will be more stable oil followed by sample C and B. From the acid value of sample C and D, if refined using caustic soda it could be used as cooking oil. Sample B could be used in industry and not for cooking because of its high phytotoxicity content.

Saponification Value observes oxidative measure on storage and level of deterioration in oil is assessed by saponification value. Sample B (193.54mgKOH/g), sample C (195.93mgKOH/g) and D (198.81mgKOH/g) had higher saponification value compare to control sample A (190.98mgKOH/g). However all the samples had lower value compared to the 224.63 reported by Sara (2016) but higher than 168.8 value from manji (2013) and 174.5 from Babeker (2013). The empirical observation confers that Balanites oil at these process treatments have high volatility, low molecular weight and can yield more energy on combustion than the control sample A, hence the potential to be used for biofuel production. Balanite oil at this crude state cannot be however use in soap making because it might have low emulsifying ability. These high saponification oil value indicates high proportion of fatty acid and inedibility of its oil except refined.

The control sample has high viscosity compare to sample B and sample D. This confers that sample A have more molecular weight, less impurity and less unsaturation level which implies it could be used for industrial applications. Soaked sample Coil have high lightedness than sample Boil but lower than control sample A.

Acid value tells of the quality of free fatty acid and extent of lipolytic hydrolysis in oil the control sample A (80.616wiji’) share similar value with the roasted sample B (80.00wiji’s), but lower values were observe in sample C (79.00wiji’s) and D (64.00wiji’s). The Balanites values were lower than those values reported by Sara (2015) as (122.43) and Okia (2010) as (98.28) respectively. There were however higher than 76.8wiji reported by Manji., et al. (2013) and 56.8wijis reported by Babeker (2013). The value of Balanites oils samples indicates that these oils are not dry oils because of their average level of unsaturation and free fatty acids. These oils can be good raw material for vegetable oil base cream Odenude., et al. (2007). When purifies could become edible vegetable oil.

Refractive index measures the relative speed of light in air to oil sample, reflecting refractivity. This generally varies based on wavelength and temperature, degree and types of unsaturation, branching and purity. Sample A had Codex 1999 recommended value of 1.46 unlike sample B (1.8), sample D (1.04) and sample C (1.50). These characteristics in sample D and C implies that these oils could foul and is impure, it cannot be easily hydrogenated or isomerized until refined.

Peroxide Value indicates lipid peroxidation and generally crude oil have high peroxide values. Sample Coil had 4.40meq/kg peroxide value similar with sample A (4.50meq/kg). The value for sample B (25.14meq/kg) and sample D (61.21meq/kg) had far higher values from the control sample and sample C. The value observed from all the samples except for ample C had higher value compared to what was reported by Sara (2015) (1.18), Manji., et al. (2013) (6.0) and Babeker (2103) (8.0). The soaked sample C value agreed with FAO/WHO (1994) standard of 10.0meq/kg peroxide values in oil suitable for consumption. The high value of peroxide in the other samples maybe as a result of contamination and may not be suitable for human consumption.

Free fatty acid confers specificity of free fatty acid in oil. The control sample had 0.50mgKOH value of free fatty acid similar to the soaked sample C (1.09mgKOH) but higher compared with the sample B (3.93mgKOH) and sample D (4.22mgKOH). These values were higher than 2.8 mgKOH and 1.84 mgKOH reported by Gutti., et al. (20011) and Manji., et al. (2013) respectively. Sample B could be compare with the 3.17mgKOH reported by Sara (2015). Sample B and C may not be suitable for refining because loss of oils may be experienced. This is also an indication that linoleic acid concentration might be high which could cause spoilage.

| Parameters | Sample A(control) | Sample B | Sample C | Sample D |

| Moisture content % | 1.54 | 0.23 | 0.05 | 0.59 |

| Acid value mg KOH/g | 1.18 | 7.854 | 2.17 | 4.44 |

| Saponification value mg KOH/g | 190.98 | 193.54 | 195.93 | 198.81 |

| Iodine value (wij’s) | 80.62 | 80 | 79 | 64.0 |

| Peroxide value meq/Kg | 4.50 | 25.14 | 4.40 | 61.20 |

| Unsaponifiable matter g/Kg | 0.003 | 0.0055 | 0.0070 | 0.0044 |

| Free fatty acid mg KOH/g | 0.51 | 3.927 | 1.085 | 4.22 |

| Viscosity m Pa/s | 50.0 | 45.0 | 46.5 | 48.0 |

| Refractive index@ 36.0oC | 1.47 | 1.8 | 1.502 | 1.645 |

Table 2: Physiochemical properties of Balanite aegyptiaca oil at various process treatment.

Key:

Sample A (Groundnut oil) winnowed, roasted seed

Sample B (Balanites oil) Roasted, winnowed seed

Sample C (Balanites oil) Soaked, winnowed, roasted seed

Sample D (Balanites oil) >B oiled, winnowed, roasted seed

Sample A (Groundnut oil) winnowed, roasted seed

Sample B (Balanites oil) Roasted, winnowed seed

Sample C (Balanites oil) Soaked, winnowed, roasted seed

Sample D (Balanites oil) >B oiled, winnowed, roasted seed

Conclusion

Oil extracted from B. aegyptiaca kernel at various process treatments of toasting only, soaking and toasting, boiling and toasting investigated revealed that oil extracted from samples of B. aegyptiaca kernels toasted only had higher oil yield compared to samples boiled and soaked. The acid value, saponification values, free fatty acid and refractive index showed high physiochemical characteristics for pretreated samples. Low moisture content, iodine values and the viscosity values were observe in B. aegyptiaca oil compared with the control sample. Oil extracted from B. aegyptiaca kernels soaked and toasted showed close edibility qualities compared to the other samples and could be better when refined.

Acknowledgement

The authors acknowledged the grant received from The Tertiary Education Trust Fund (Tet Fund) through the Federal University, Gashua, Nigeria which made it possible to carry out this work.

The authors acknowledged the grant received from The Tertiary Education Trust Fund (Tet Fund) through the Federal University, Gashua, Nigeria which made it possible to carry out this work.

References

- Alexander KS. Canola oil In, Handbook of Pharmaceutical excipients, 5th edition (PhP &APhA, (2009).

- AOAC. Official Method of Analysis, 17th ed., Association of Official Analytical Chemists, USA (2000).

- British standard Institute Methods B.S.I (1958). Analysis of Oils and Fats 684.

- Babeker MA., et al. Physicochemical Properties of Laloub Seed Oil. M .Sc thesis .29-45 .Faculty of Agriculture University of Khartoum (2013).

- Babagana G., et al. “Characterization and Composition of Balanites aegyptiaca seed oil and its potential as biodiesel feed stock in Nigeria”. Journal of Tapplied Phytotechnology in environmental sanitation1.1 (2011): 29-35.

- Codex Alimentarius. “Codex standards for named vegetable oils”. 8 (2001).

- Chapagain BP., et al. “Desert date (Balanites aegyptiaca) as an arid lands sustainable bioresource for biodiesel”. Bioresource Technology 100.3 (2009): 1221-1226.

- Chapagain B and Wiesman Z. “Larvicidal effects of aqueous extracts of Balanites aegyptiaca (desert date) against the larvae of Culex pipiens mosquitoes”. African Journal of Biotechnology 4.11 (2005): 1351-1354.

- FAO/WHO. Fats and oils in human nutrition: FAO Food and Nutrition Paper No 57. FAO, Rome. (1994).

- Gardette JL and M Baba. “FTIR and DSC studies of the thermal and photochemical stability of Balanites aegyptiaca oil (Toogga oil)”. Chemistry and Physics of Lipids (2013): 170-171.

- Cocks LV and Van Rede C. Laboratory handbook for Oil and Fat Analysis. Academic Press Inc. Ltd., London, New York. (1966).

- Fawad AA. Industrail oils and fats. First edition, Egypt University Press, Wafa bookshop. (1993).

- FAO/WHO. Fats and oils in human nutrition: FAO Food and WHO. Vitamin and mineral requirements in human nutrition. Appendix 1: Recommended nutrient intakes. (1994).

- Goldberg G. Plants: Diet and Health. The Report of the British Nutrition Foundation Task Force. Blackwell, Oxford, Phytochemical Constituents of Seeds of Ripe (2003): 40.

- Lohlum S A., et al. “Enhancing the Chemical Composition of Balanites aegyptiaca Seeds through Ethanol Extraction for Use as a Protein Source in Feed Formulation.” Sustainable Agriculture Research 1.2 (2012): 251.

- Oderinde KA., et al. “Characterization of Seed and Seeds oil of Hura crepitans and the Kinetics of Degradation of the Oil during Heating.” Electronic Journal of Environment, Agriculture & Food Chemistry 8.3 (2009).

- Okia CA., et al. “Nutritional Value of Commonly Consumed Desert Date Tree Products”. African Crop Science Journal 21 (2013): 657-667.

- Ong AS., et al. Developments in Palm Oil. In Developments in Oils and Fats (R.J. Hamilton, editors). Pp, Blackie Academic and Professional, Glasgow (1995): 153-191.

- Pearson D. The Chemical Analysis of Food (8Ed).J. A. Churchill London, (1981): 535.

- Sara MEF. Physicochemical Properties of Balanites aegyptiaca (Laloub) Seed Oil. A thesis Submitted in Partial Fulfillment for the Requirements of the Degree ofMaster of Science in Food Science and Technology. Sudan University of Science and Technology College of Graduate Studies. (2015).

- McKevith B. “Nutritional aspects of oilseeds.” British Nutrition Foundation, London,UK, British Nutrition Foundation, Nutrition Bulletin 30 (2005): 13-26.

- Manji A J., et al. “Studies on the potentials of Balanites aegyptiaca seed oil as raw material for the production of liquid cleansing agents”. Department of Industrial Chemistry, Modibbo Adama University of Technology, P. M. B. 2076, Yola, Adamawa State, Nigeria. (2013).

- McKevith B. “Nutritional aspects of oilseeds”. Nutrition Bulletin 30.1 (2005): 3-26.

- Manji AJ., et al. “Studies on the potentials of Balanites aegyptiaca seed oil as raw material for the production of liquid cleansing agents”. International Journal of Physical Sciences 8.33 (2013): 1655-1660.

- National Research Council NRC. Lost Crops of Africa. Volume III: Fruits, Washington, D.C.: The National Academies Press. (2008).

- Omujal F., et al. (20080 Post harvest handling practices and physicochemical characteristics of shea butter in Uganda. Msc. Thesis, Department of Chemistry, Makerere University, Kampala, 94.

- Okia CA. Balanites aegyptiaca: A resource for Improving Nutrition and Income of Dryland Communities in Uganda. A thesis submitted in candidature for the degree of Philosophiae Doctor (Agroforestry) of Bangor University School (2010).

- Onuekwusi EC., et al. “Phytochemical Constituents of Seeds of Ripe and Unripe Blighia Sapida (K. Koenig) and Physicochemical Properties of the Seed Oil”. International Journal of Pharmaceutical Science Invention3.9 (2014): 31-40.

- WHO. "Vitamin and mineral requirements in human nutrition. Appendix 1: Recommended nutrient intakes. WHO, Geneva, Switzerland (2004).

Citation:

Ogori AF. “Oil Yield and Physiochemical Properties of Balanites aegyptiaca (l.) del. Kernels at Various Process Treatments”.

Nutrition and Food Toxicology 2.5 (2018): 467-473.

Copyright: © 2018 Ogori AF. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.