Research Article

Volume 2 Issue 6 - 2018

Effects of Taro Varieties and Blending Ratios on Proximate Compositions, Sensory Qualities and Overall Acceptability of Taro (Colocasia esculenta) –Wheat (Aestium triticium) Composite Bread

Mizane tepi university horticulture department with MSc. in post-harvest management. Ethiopia

*Corresponding Author: lamrot woldemariam, Mizane tepi university horticulture department with MSc. in post-harvest management. Ethiopia.

Received: April 20, 2018; Published: May 22, 2018

Abstract

Although taro is widely grown in Ethiopia, it is one of the underutilized crop which is a good source of carbohydrate and minerals. This experiment was conducted to explore the effects of taro varieties and blending ratios on proximate compositions, anti-nutritional factors and sensory qualities of taro-wheat composite bread. Three levels of taro verities (Danu No 34, Kiak No 33 and local), three levels of blending ratios (10g, 20g and 30g of taro in 100g of control wheat flour were used and the treatments were factorial arranged in complete randomized design with three replications. Blending with Danu No 34, Kiak No 33 and local varieties had reduced moisture content to 4.42%, 3.85% and 3.78% respectively as compared to the moisture content (5.2%) in the control (100% wheat bread). Similarly, protein content dropped to 31.1%,27.87%, 30.28% from 36.79%, crude fat content, 5.05%, 5.31% and 4.34% from 5.4% and energy 407.54 kcal/100g, 410.07 kcal/100g, and 405.73 kcal/100g, from 421.63 kcal/100g, increased iron content 69.01mg/kg/, 87, 98mg/kg and 97.92mg/kg from 52.40mg/kg, crude fiber content increased to3.48%,2.32% and 3.31% from 2.67% and utilizable carbohydrate content increased to 62.59%, 63.74% and 62.73% from 52.30%. With increase in blending ratio. Highly Significant (P < 0.05) differences were observed in overall acceptability of the composite breads due to blending ratios. As the blending ratio increased the overall acceptability dropped significantly (P < 0.05). It could be concluded that the substitution of taro flour with wheat flour in bread making with substitution level up to 20g did not adversely affect the quality properties of the bread and produce bread comparable to that produced from wheat flour. Further studies are required to investigate the impacts on taro flour storage period.

Keywords: Blending; Composite bread; Proximate composition and Sensory acceptability

Introduction

Roots and Tubers have a short-shelf life because of their high moisture content and start rotting as early as 2 weeks post-harvesting. In order to minimize tuber losses, they must be converted from perishable to non-perishable through food processing operations (Aboubakar., et al. 2008). One of the best ways to preserve them is by processing them into flour and/or starch (Perez., et al. 2005). Among the root crops, taro is perhaps most widely prepared or processed into more consumable forms in the world.

Taro (Colocasia esculenta (L.) Schott) is a major tuber crop cultivated in the tropical and subtropical regions of the world (FAO, 2008). Taro roots contain a wealth of organic compounds, minerals, and vitamins that are essential for human health and can benefit our overall health in a number of different ways [Ron., et al. 1983]. Like most foods of plant origin, taro contains a variety of anti-nutritional and toxic components such as oxalates, phytates, trypsin and amylase inhibitors, tannins and cyanide. Therefore, it is advisable to process taro before consumption (FAO, 1999). Therefore, the objective of this research was to determine the effects of blending ratios and taro varieties on Proximate Composition, sensory qualities and over all acceptability of taro- wheat composite bread.

Materials and Methods

Experimental Site

The study was conducted in Mizan Tepi University in Bench Maji Zones of SNNPRS during 2015-2018 year. Bench Maji Zone is one of the zones in Southern Nations Nationalities and People Region State of Ethiopia. The total land area of the zone is about 19,326.6 km2. It is bordered by Keffa in the north east, DebubOmo in the south east, Sudan on the south west and Gambela in the North West and Sheka in the North. The altitudinal variation of the zone ranges between 500 to 3000 m.a.s.l. It is located in 34°88'-36°14' E and 5°33'-7°21'N (SNNPR, 2008). The rainfall ranges from 1200 mm/year to over 2000 mm/year. (IFPRI and CSA, 2006). The average temperature ranges from 22°C to 27°C (BMZBoFED, 2006).

The study was conducted in Mizan Tepi University in Bench Maji Zones of SNNPRS during 2015-2018 year. Bench Maji Zone is one of the zones in Southern Nations Nationalities and People Region State of Ethiopia. The total land area of the zone is about 19,326.6 km2. It is bordered by Keffa in the north east, DebubOmo in the south east, Sudan on the south west and Gambela in the North West and Sheka in the North. The altitudinal variation of the zone ranges between 500 to 3000 m.a.s.l. It is located in 34°88'-36°14' E and 5°33'-7°21'N (SNNPR, 2008). The rainfall ranges from 1200 mm/year to over 2000 mm/year. (IFPRI and CSA, 2006). The average temperature ranges from 22°C to 27°C (BMZBoFED, 2006).

Material preparation

Wheat was sourced from Mizan Teferi market and Kiak No 33 and Danu No 34 of taro were sourced from Jima Agricultural Research Center (JARC) and local variety was sourced from Mizan-Teferi Model Farmer.)

Wheat was sourced from Mizan Teferi market and Kiak No 33 and Danu No 34 of taro were sourced from Jima Agricultural Research Center (JARC) and local variety was sourced from Mizan-Teferi Model Farmer.)

Treatments and Experimental Design

The experimental work was conducted using three level of blending ratios [100g whole wheat as control, 10: 100g (B1), 20g: 100g (B2) and 30g: 100g (B3)], three levels of taro varieties (Kiak No 33 , Danu No 34 and Local Variety ) and the treatments were Factorial Arranged in Completely Randomize Design (CRD) with three Replications.

The experimental work was conducted using three level of blending ratios [100g whole wheat as control, 10: 100g (B1), 20g: 100g (B2) and 30g: 100g (B3)], three levels of taro varieties (Kiak No 33 , Danu No 34 and Local Variety ) and the treatments were Factorial Arranged in Completely Randomize Design (CRD) with three Replications.

Sample Preparation

Wheat flour was packed in polyethylene plastic bags and finally stored at room temperature until required for the experiment.

Wheat flour was packed in polyethylene plastic bags and finally stored at room temperature until required for the experiment.

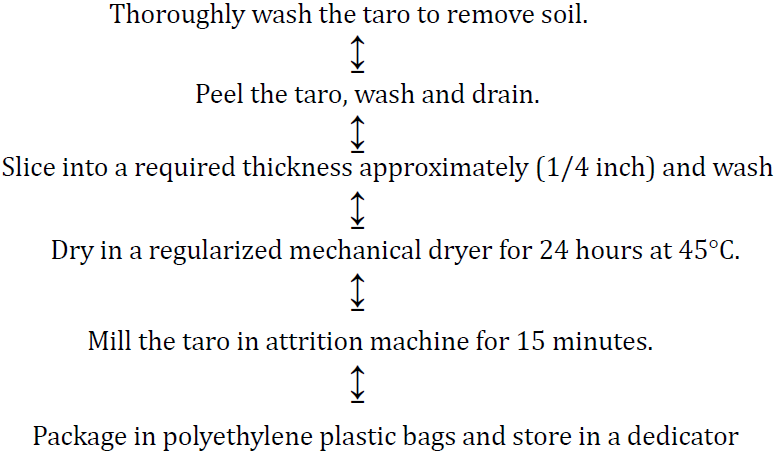

Preparation of Flour from Taro (Colocasia esculenta): Flour of taro was obtained using the conventional dehydration techniques as described by (Nip., et al. 1997). After harvesting taro, the tubers were processed immediately within a day on arrival at laboratory. The infected roots were sorted, cleaned and rinsed with a large amount of tap water to remove soil and then peeled manually with knife, sliced in to chips by slicer machine. The sliced taro chips were soaked in water for 24 hours to detoxify. The chips were oven-dried in clean trays for about 45°C for 24 hours. Dried slices were fine milled into flours (with granules size pass through 60- mesh screen) using commercial mill and then packed in polyethylene plastic bags. Finally stored at room temperature until required for the experiment.

A summary of the preparation of the taro flour is presented in a flow chart

The above method will use for all the samples

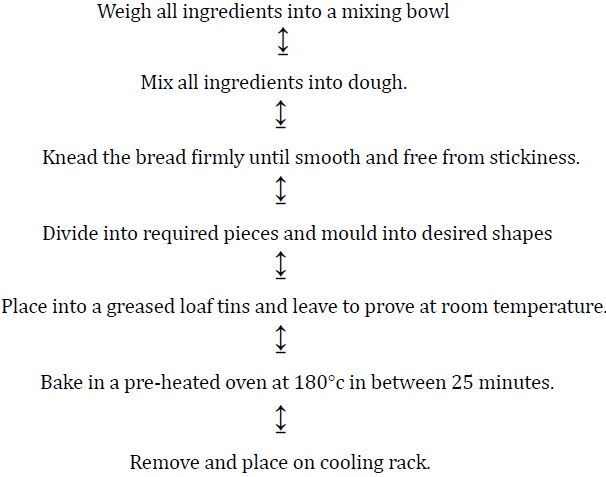

Figure 2: Flow Chart for Preparation of Bread, Source: (Rita, 2011).

Figure 2: Flow Chart for Preparation of Bread, Source: (Rita, 2011).

Bread preparation

The method used by (IITA, 2005) International Institute of Tropical Agriculture was used. The Bread were baked with the ingredients composition expressed as the percentage of flour used as 100g wheat flour and 10g, 20g, and 30g taro flour, 43% tap water, 8.3g Sugar, 0.9g salts, and 0.6g dried yeast and 0.4g vanilla flavor. Bread baked with 100% wheat flour will used as control. Dough was prepared by blending the composite flours. Dried ingredients were mixed together and then the dough was prepared by kneading the mixed ingredients by hand with water for 20 min. molded into loaves and proofed for 3 hr at room temperature (28°C) (Eriksson., et al. 2009). The loaves was baked in oven at 180°C for 25 min. the samples was allowed to cool to room temperature and was store in polyethylene bags for further analysis. To make the bread suitable for proximate and anti-nutritional analysis is the bread samples were dried (100°C for 24h), milled into flours and stored in an airtight container at refrigeration temperature (5°C) until analysis was done. (Ayele., et al. 2017)

The method used by (IITA, 2005) International Institute of Tropical Agriculture was used. The Bread were baked with the ingredients composition expressed as the percentage of flour used as 100g wheat flour and 10g, 20g, and 30g taro flour, 43% tap water, 8.3g Sugar, 0.9g salts, and 0.6g dried yeast and 0.4g vanilla flavor. Bread baked with 100% wheat flour will used as control. Dough was prepared by blending the composite flours. Dried ingredients were mixed together and then the dough was prepared by kneading the mixed ingredients by hand with water for 20 min. molded into loaves and proofed for 3 hr at room temperature (28°C) (Eriksson., et al. 2009). The loaves was baked in oven at 180°C for 25 min. the samples was allowed to cool to room temperature and was store in polyethylene bags for further analysis. To make the bread suitable for proximate and anti-nutritional analysis is the bread samples were dried (100°C for 24h), milled into flours and stored in an airtight container at refrigeration temperature (5°C) until analysis was done. (Ayele., et al. 2017)

Proximate and Sensory Analysis of composite Bread

Breads produced from the taro -wheat composite flours were used to proximate analysis and sensory evaluation. The percentage of moisture (AOAC 925.10), ash (modified AOAC 923.03), crude fat (AOAC920.39, 960.39), crude protein ((ISO 1871:2013), Nitrogen to protein conversion factor of 6.25 was used, iron (modified AOAC 985.35) and crude fiber (AOAC962.09) of the accepted composite breads was carried out using recommended standard methods. Carbohydrate was calculated by difference. Bread loaves were allowed cooling for 1 hr and cutting into slices of uniform thickness and transferred onto white color plates coded with random 3-digit codes. A sensory panel consisting of 50 semi-trained staff members (30 males and 20 females) at Mizan Tepi University and familiar with sensory attributes of local bread was employed to rate the breads for color, appearance, taste, texture, flavor and overall acceptability. These attributes was rate on a 5-point hedonic score scale as: 1 (extremely dislike), 2 (dislike moderately); 3 (neither like nor dislike), 4 (like moderately) to 5 (extremely like) (Lawless and Heymann, 2010).

Breads produced from the taro -wheat composite flours were used to proximate analysis and sensory evaluation. The percentage of moisture (AOAC 925.10), ash (modified AOAC 923.03), crude fat (AOAC920.39, 960.39), crude protein ((ISO 1871:2013), Nitrogen to protein conversion factor of 6.25 was used, iron (modified AOAC 985.35) and crude fiber (AOAC962.09) of the accepted composite breads was carried out using recommended standard methods. Carbohydrate was calculated by difference. Bread loaves were allowed cooling for 1 hr and cutting into slices of uniform thickness and transferred onto white color plates coded with random 3-digit codes. A sensory panel consisting of 50 semi-trained staff members (30 males and 20 females) at Mizan Tepi University and familiar with sensory attributes of local bread was employed to rate the breads for color, appearance, taste, texture, flavor and overall acceptability. These attributes was rate on a 5-point hedonic score scale as: 1 (extremely dislike), 2 (dislike moderately); 3 (neither like nor dislike), 4 (like moderately) to 5 (extremely like) (Lawless and Heymann, 2010).

An atmosphere of complete quietness and privacy was provided for each panelist. The sensory evaluation was conducted in 9:30 pm and a randomized complete block design was used in which the samples were randomly assigned to each panelist (Rampersad., et al. 2003 and Hooda and Jood, 2005). Four bread samples were evaluated at a time and individually to the panelists along with water. Samples receiving an overall quality score of ≥ 3 will consider acceptable (Gizachew., et al. 2015).

Statistical Analysis

The experiment was carried out using a completely randomized design (CRD) in factorial arrangement method as outlined by Steel and Torrie (1980). Three replicates per treatment was evaluated for the effect of taro variety and blending ratio proximate composition, anti-nutritional factors analysis, sensory qualities and overall acceptability of taro-wheat composite bread. The data was analyzed by using an Analysis of Variance (ANOVA). Where possible, mean comparisons was done using the List Significance Difference (LSD) at p ≤ 0.05. Statistical analysis was carried out using the SAS (Version 9.0) system.

The experiment was carried out using a completely randomized design (CRD) in factorial arrangement method as outlined by Steel and Torrie (1980). Three replicates per treatment was evaluated for the effect of taro variety and blending ratio proximate composition, anti-nutritional factors analysis, sensory qualities and overall acceptability of taro-wheat composite bread. The data was analyzed by using an Analysis of Variance (ANOVA). Where possible, mean comparisons was done using the List Significance Difference (LSD) at p ≤ 0.05. Statistical analysis was carried out using the SAS (Version 9.0) system.

Result and Discussion

Proximate Composition of The Composite Bread

Moisture Content

The high moisture content of fresh taro corms is a limitation of production and utilization of taro. One possible method to overcome the post-harvest loss is converting the products into flours of low moisture content Adane., et al. 2013). Moisture is an important parameter in the storage of flours, levels greater than 12% allow for microbial growth. Low levels are favorable and give relatively longer shelf life (Aryee., et al. 2006).

Moisture Content

The high moisture content of fresh taro corms is a limitation of production and utilization of taro. One possible method to overcome the post-harvest loss is converting the products into flours of low moisture content Adane., et al. 2013). Moisture is an important parameter in the storage of flours, levels greater than 12% allow for microbial growth. Low levels are favorable and give relatively longer shelf life (Aryee., et al. 2006).

There was a significant difference (P < 0.05) among blending ratios for Moisture content of taro flours composite bread samples (Table 1). The Highest Moisture content of the composite breads was observed for control wheat flour bread (5.2%). Followed by 20g taro flour (4.36%) which is statistically similar with 10g taro flour (4.13%) and the least was recorded for 30 g taro flour blending (3.53%). The Moisture content of control wheat bread (5.2%) was significantly (p < 0.05) higher when compared with those of the composite bread samples. The moisture content of samples was decreased as level of supplementation of taro flour increased above 20g.

At the highest baking temperature the moisture content of the bread samples must have been greatly reduced. However, different food materials have different capacity for absorbing moisture which may exist as absorbed water. As a result, it can be deduced that even at high baking temperature (Eddy, 2004). This result is similar with the work of (Mongi., et al. 2011) that, the moisture content of the samples decreased with increase in the levels of cocoyam flour.

There was a significant difference (P < 0.05) in Moisture content of composite bread samples due to variety (Table 1). The Highest Moisture content of taro flour composite breads was observed due to control wheat flour bread (5.2%) Followed by Danu variety (4.42%) this was statistically similar with kiak and local variety (3.85% and 3.78%) respectively.

Ash content

There was a significant difference (P < 0.05) among blending ratios for ash content of taro flours composite bread samples (Table 1). The ash content of the control sample was 2.32%, for 30g taro flour it was 2.69%, for 20g taro flour 2.59% and for the 10g taro flour 2.46%. Generally, the ash content of composite bread samples increased as the level of supplementation increased implying that taro flours had positively impacted on inorganic nutrients in the composite bread. In similar to the current results (Sanful, 2011) the ash content of bread with taro was increased with the increment of taro in the formula. The findings of (Ammar., et al. 2009, Ayele., et al. 2017 and Rita, 2011) also shown that increase of substitution ratio of wheat flour with taro flour resulted in an increase in ash content and the ash content of the composite bread samples increased from 3.84 to 4.23% with supplementation of soybean flour increase from 10 to 30%.

There was a significant difference (P < 0.05) among blending ratios for ash content of taro flours composite bread samples (Table 1). The ash content of the control sample was 2.32%, for 30g taro flour it was 2.69%, for 20g taro flour 2.59% and for the 10g taro flour 2.46%. Generally, the ash content of composite bread samples increased as the level of supplementation increased implying that taro flours had positively impacted on inorganic nutrients in the composite bread. In similar to the current results (Sanful, 2011) the ash content of bread with taro was increased with the increment of taro in the formula. The findings of (Ammar., et al. 2009, Ayele., et al. 2017 and Rita, 2011) also shown that increase of substitution ratio of wheat flour with taro flour resulted in an increase in ash content and the ash content of the composite bread samples increased from 3.84 to 4.23% with supplementation of soybean flour increase from 10 to 30%.

Correspondingly, (Samue and John 2014) also reported that the ash content was increased with increased sweet potato flour substitution of maize which showed that blending cereal flour with root and tuber crops can enhance proximate composition. In this regard, the possible increment of ash content with increasing taro could be due to the fact that taro is rich source of minerals and it is imperative to blend wheat flour with it to enhance the mineral content. In fact compared to wheat flour, it was found that taro flours contained appreciable amounts of minerals and Because of the low protein and high ash content in taro flours, the substitution of wheat by taro flour will result in reduction of protein and increase in ash content of composite flours or biscuits (Makhlouf, 2012),

There was a significant difference (P < 0.05) in ash content of composite bread samples due to variety (Table 1). The three varieties of taro had statistically similar ash content (Danu variety, 2.55%, kiak variety 2.60% and for local varieties, 2.59%) of the composite breads which was found to be greater than that of composite bread samples. In similar results were done by (Sanni., et al. 2005). The lowest ash content was recorded for control wheat bread sample (2.32%).

There was a significant difference (P < 0.05) in ash content of composite bread samples due to interaction of variety and blending ratio (Table 2). The Highest ash content of taro flour composite breads was observed due to kiak variety with 30g taro flour (2.76%) which was statistically similar with Danu variety with 30g taro flour (2.67), local variety with 20 and 30g of taro flour (2.62%) and the least was recorded for kiak with 10g of taro flour (2.4%).

Iron content

There was a significant difference (P < 0.05) in Iron content of composite bread samples due to variety (Table 1). The highest iron content of taro flour composite breads was observed due to Local, Kiak and Danu varieties (97.91 mg/kg), (87.98 mg/kg) and (69.01 mg/kg) respectively which was greater than that of the control sample which is wheat flour (52.40 mg/kg).

There was a significant difference (P < 0.05) in Iron content of composite bread samples due to variety (Table 1). The highest iron content of taro flour composite breads was observed due to Local, Kiak and Danu varieties (97.91 mg/kg), (87.98 mg/kg) and (69.01 mg/kg) respectively which was greater than that of the control sample which is wheat flour (52.40 mg/kg).

There was a significant difference (P < 0.05) among blending ratios for iron content of taro flours composite bread samples (Table 1). Highest iron content of the composite breads was observed for 30g taro flour (91.91 mg/kg), for 20g taro flour (87.47 mg/kg) which is followed by 10g taro flour (75.52 mg/kg) which was greater than that of the control wheat flour bread (52.41 mg/kg). There was an interaction effect between blending ratios and taro varieties for iron content of composite bread samples (Table 2). The highest was recorded in local varieties with 30g taro flour (98.95mg/kg) which was statistically similar with local varieties with 20g taro flour (98.13mg/kg), Kiak varieties with 30g taro flour (97.46mg/kg) and the least was recorded for Danu varieties with blending ratio of 10g taro flour (47.65mg/kg).

Crude fat

Blending ratios showed significant difference (P > 0.05) on crude fat content among the composite bread samples (Table 1). The crude fat of composite bread samples were for 5.4% for control bread sample which is statistically similar with blending ratio of 10g taro flour (5.3%), for the 20g taro flour 4.78% which is statistically similar with 30g taro flour 4.64%. The wheat bread sample (5.4%) was observed higher crude fat content than those of the composite bread samples with 20g taro flour and above.

Blending ratios showed significant difference (P > 0.05) on crude fat content among the composite bread samples (Table 1). The crude fat of composite bread samples were for 5.4% for control bread sample which is statistically similar with blending ratio of 10g taro flour (5.3%), for the 20g taro flour 4.78% which is statistically similar with 30g taro flour 4.64%. The wheat bread sample (5.4%) was observed higher crude fat content than those of the composite bread samples with 20g taro flour and above.

The low fat content of the composite breads could be due to the presence of fat in the taro flour at lower amount (4.64%) than in wheat flour (2%) (O'Brien., et al. 1992). The low content of fat will enhance the storage life of the food products due to the lowered chance of rancid flavor development (Gizachew., et al. 2015). This finding was in line with `(Rita, 2011) in which crude fat of whole wheat bread found to be almost two times that of taro based breads.

Taro varieties showed significant difference (P < 0.05) on crude fat content among the composite bread samples (Table 1). The highest crude fat content was recorded for control bread sample (5.4%) which is statistically similar with Kiak variety (5.31%) which is followed by Danu varieties (5.05%) and the least is for local varieties (4.34%). The low content of fat in local variety will enhance the storage life of the food products due to the lowered chance of rancid flavor development.

There was an interaction effect between blending ratios and taro varieties for crude fat content of composite bread samples (Table 2). The highest crude fat content was recorded for kiak variety with blending of 10g taro flour (6.01%) which is statistically similar with Danu variety with blending of 20g taro four (5.83%) which is followed by kiak variety with 20g taro flour (5.17%) and the least one is local variety with 20g taro flour (3.32%).

| Trts | Iron mg/kg | Moisture (%) | Ash (%) | Fat (%) | Fiber (%) | Protein (%) | CHO (%) | Energy (kcal/100g) | PH | |

| Main effects of blending ratio | ||||||||||

| WB1 | 75.52c | 4.17b | 2.46b | 5.3a | 2.92b | 33.33b | 53.69c | 410.17b | 5.85a | |

| WB2 | 87.47b | 4.36b | 2.59a | 4.78b | 2.8c | 29.39c | 62.45b | 406.65c | 5.72ab | |

| WB3 | 91.91a | 3.53c | 2.69a | 4.64b | 3.44a | 26.53d | 72.92a | 406.53c | 5.54b | |

| Cont. | 52.41d | 5.20a | 2.32c | 5.4a | 2.67d | 36.79a | 52.30d | 421.63a | 5.76ab | |

| Cv (%) | 1.17 | 7.55 | 4.68 | 2.99 | 4.77 | 2.01 | 0.32 | 5.15 | ||

| LSD (%) | 0.87 | 0.31 | 0.11 | 0.13 | 0.15 | 0.50 | 1.93 | 1.28 | 0.49 | |

| Main effects of varieties | ||||||||||

| WD | 69.01c | 4.42b | 2.55a | 5.05b | 3.48a | 31.10b | 62.59b | 407.54c | 5.88a | |

| WK | 87.98b | 3.85c | 2.60a | 5.31a | 2.32c | 27.87d | 63.74a | 410.07b | 5.47b | |

| WL | 97.91a | 3.78c | 2.59a | 4.34c | 3.31a | 30.28c | 62.73ab | 405.73d | 5.76a | |

| Cont. | 52.40d | 5.20a | 2.32b | 5.4a | 2.67b | 36.79a | 52.30c | 421.63a | 5.76a | |

| Cv (%) | 1.12 | 7.50 | 4.58 | 2.86 | 10.18 | 1.74 | 1.93 | 0.32 | 4.96 | |

| LSD (%) | 0.83 | 0.31 | 0.11 | 0.13 | 0.29 | 0.53 | 1.13 | 1.29 | 0.27 | |

Table 1: Main effects of blending ratio on proximate composition of taro –wheat composited breads.

NS = Non-Significance different at 5% probability level. Values with the same letters in the same column are not significantly different at 5% level of significance according to LSD test. Cont. = control (100g wheat flour bread, WB1 (100g wheat with 10g taro), WB2 (100g wheat with 20g taro) and WB3 (100g wheat with 30g taro) and C.V (coefficient of variance), LSD (list significant difference), WD (wheat with Danu variety), WK (wheat with kiak variety), and WL (wheat with local variety)

Crude fiber

There was a significant difference (P < 0.05) in crude fiber content of composite breads due to various blending ratios (Table 1). The crude fiber content of the composite breads increased with increase e in substitution of taro flour for 30g taro flour (3.44%) followed by 10g taro flour (2.92%) and the least is recorded for the control 100g wheat flour sample (2.67%). This finding was similar with Gizachew., et al. 2015) in which the crude fiber content of the composite breads increased with increase in substitution of cassava flour.

There was a significant difference (P < 0.05) in crude fiber content of composite breads due to various blending ratios (Table 1). The crude fiber content of the composite breads increased with increase e in substitution of taro flour for 30g taro flour (3.44%) followed by 10g taro flour (2.92%) and the least is recorded for the control 100g wheat flour sample (2.67%). This finding was similar with Gizachew., et al. 2015) in which the crude fiber content of the composite breads increased with increase in substitution of cassava flour.

The increase might have been due to the fiber content in the taro flour which increased with increase in its level in the composite flour. According to previous research wheat bread may contain 0.6-1.9% insoluble fiber and 0.1-2.8% soluble fiber (Prosky., et al. 1994) making the total content of fiber up to 0.7 and 4.7%. The significant increase in the fiber content of cocoyam flour was due the reason that, wheat flour had lower fiber content values (0.29%) compared to cocoyam flour (Monji., et al. 2011). According to Schneeman (2002) the crude fiber contributes to the health of the gastrointestinal system and metabolic system in man. Because crude fiber consists of cellulose and lignin, its estimation affords an index for evaluation of dietary fiber whose efficiency has been implicated in a variety of gastrointestinal disorder. By increasing intestinal mobility, fiber causes increased transit time for bile salt derivatives as deoxycholate, which are effective chemical carcinogen, hence reducing incidence of carcinoma of the colon (Monji., et al. 2011)

Taro varieties showed significant difference (P < 0.05) on crude fiber content among the composite bread samples (Table 1). The highest crude fiber content was recorded for dame variety (3.48%) which is statistically similar with local variety (3.31%) the least is for control sample (2.67%).

There were interaction effects between blending ratios and taro varieties for crude fiber content of composite bread samples (Table 2). the highest crude fiber content was recorded for local variety with blending of 20g taro flour (4.16%) which is statistically similar with Danu variety with blending of 30g taro four (4.04%) and the least one is kiak variety with 30g taro flour (2.30%).

Crude protein

There was a significant difference (P < 0.05) in crude protein content of composite breads due to various blending ratios (Table 1). The highest crude protein content was recorded in the control sample (36.79 %) followed by 10g taro flour (33.33%) and the least was 30g taro flour (26.53%). This indicates that protein content decreases as the blending ratio of taro increases. this finding is similar with the finding of Njintang., et al. 2007 and 2008, Rita, 2011 and Makhlouf, 2012).

There was a significant difference (P < 0.05) in crude protein content of composite breads due to various blending ratios (Table 1). The highest crude protein content was recorded in the control sample (36.79 %) followed by 10g taro flour (33.33%) and the least was 30g taro flour (26.53%). This indicates that protein content decreases as the blending ratio of taro increases. this finding is similar with the finding of Njintang., et al. 2007 and 2008, Rita, 2011 and Makhlouf, 2012).

It is clear that protein content of wheat flour was higher than that of taro flour, therefore substitution of wheat flour with taro flour would slightly decreased the protein content of weaning food; the decrease was proportional to the substitution level (Afaf., et al. 2013). These results were expected and compatible with the EOSQ (2005). The significant decrease in the protein content in composite breads with increasing levels of cocoyam flour substitution may be explained by the fact that, cocoyam is a poor source of protein. It is a good source of carbohydrate predominantly starchy and consumed as an energy yielding food (Monji., et al. 2011 and Gizachew., et al. 2015)

There was a significant difference (P < 0.05) in crude protein content of composite breads due to various taro varieties (Table1). Highest crude protein content was recorded in the control sample (36.79%) followed by Danu variety (31.10%) and the least was kiak variety (27.87%).

There was an interaction effect between blending ratios and taro varieties for crude protein content of composite bread samples (Table 2). the highest crude protein content was recorded for control sample (37.34%) which is statistically similar with Danu variety with blending of 30g taro four (34.52%) and the least one is kiak variety with 30g taro flour (24.67%).

Utilizable Carbohydrate (CHO)

Taro is an important staple food in several regions of developing countries because it contains high amounts of carbohydrates and is an excellent energy supplier (Huang., et al. 2007).

Taro is an important staple food in several regions of developing countries because it contains high amounts of carbohydrates and is an excellent energy supplier (Huang., et al. 2007).

There was a significant difference (P < 0.05) in carbohydrate content of composite breads due to various blending ratios (Table 1). Highest carbohydrate content was recorded in the 30g taro flour (72.92 %) followed by 20g taro flour (62.45%) and the least was recorded in control sample (52.30%). Increase in the blending levels of taro flour resulted in an increased in the carbohydrate content progressively from 52.30% of 100g wheat flour to 53.69%, 62.45% and 72.92% for breads with10g, 20g and30g taro flour composites, respectively. This is attributed to the high content of carbohydrate in taro flours and this finding is in line with the work of Gizachew., et al. 2015). Moreover, the observed significant increase in carbohydrate with increase in cocoyam substitution levels may be attributed to the high contents of carbohydrate in cocoyam (Monji., et al. 2011). The carbohydrate predominates all solid nutrients in roots and tubers (Enware, 1998).

There was a significant difference (P < 0.05) in carbohydrate content of composite breads due to various taro varieties (Table 1). Highest carbohydrate content was recorded in the kiak variety (63.74%) which is statistically similar with local variety (62.73%) followed by Danu variety (62.59%) and the least was control sample (52.30%).

There was an interaction effect between blending ratios and taro varieties for carbohydrate content of composite bread samples (Table 2). The highest carbohydrate content was recorded for kiak variety with 30g taro flour (74.28%) which is statistically similar with Danu variety with blending of 30g taro four (72.30%) followed by local variety with 30g taro flour (72.17%) and the least was control sample (52.43%).

Total energy in kilo calories

There was a significant difference (P < 0.05) in Total energy content of composite breads due to various blending ratios (Table 1). The highest Total energy content was recorded in the control sample (421.63 kcal/100g) followed by 10g taro flour (410.17 kcal/100g) and the least was recorded in 30g taro flour (406.53 kcal/100g).

There was a significant difference (P < 0.05) in Total energy content of composite breads due to various blending ratios (Table 1). The highest Total energy content was recorded in the control sample (421.63 kcal/100g) followed by 10g taro flour (410.17 kcal/100g) and the least was recorded in 30g taro flour (406.53 kcal/100g).

There was a significant difference (P < 0.05) in Total energy content of composite breads due to various taro varieties (Table 1). The highest Total energy content was recorded in the control sample (421.63 kcal/100g) followed by kiak variety (410.07 kcal/100g) and the least was Danu variety (405.73 kcal/100g). This finding was similar with (Makhlouf, 2012) in which the wheat flour total energy was greater that of the taro varieties.

There were interaction effects between blending ratios and taro varieties for energy content of composite bread samples (Table 2). the highest energy content was recorded for control sample (422.5 kcal/100g) followed by kiak variety with 10g taro flour (414.4 kcal/100g) and the least was local variety with 10g (399.8 kcal/100g).

| Trts | MC(%) | Ash(%) | Fiber(%) | Fat(%) | Fe(mg/kg) | Pro(%) | CHO(%) | Energy (Kcal/100g) | Ph |

| DB1 | 4.76bcd | 2.44cde | 3c | 4.73c | 47.65g | 34.52b | 52.95de | 404.46g | 5.89a |

| DB2 | 4.57cde | 2.53cde | 3.40b | 5.83a | 80.04e | 30.65e | 62.51c | 410.74cd | 5.95a |

| DB3 | 4.94abc | 2.67ab | 4.04a | 4.63c | 79.32e | 28.12f | 72.30ab | 407.4ef | 5.81ab |

| KB1 | 3.88fg | 2.4ed | 2.43e | 6.01a | 82.24d | 32.05b | 53.57de | 414.4b | 5.8ab |

| KB2 | 3.77fg | 2.63abc | 2.4e | 5.17b | 84.23c | 26.90g | 63.38c | 409.32de | 5.38bc |

| KB3 | 4.29def | 2.76a | 2.30e | 4.74c | 97.46ab | 24.67h | 74.28a | 406.43fg | 5.23c |

| LB1 | 3.53g | 2.53bcd | 2.70d | 5.15b | 96.67b | 33.42c | 54.55d | 411.59c | 5.86ab |

| LB2 | 4.19ef | 2.62abc | 3.07c | 3.32d | 98.13ab | 30.62e | 61.46c | 399.8h | 5.85ab |

| LB3 | 4.35def | 2.62abc | 4.16a | 4.55c | 98.95a | 26.80g | 72.17b | 405.72fg | 5.57abc |

| Cont. | 5.26a | 2.3ed | 3c | 5.4b | 52.42f | 37.34a | 52.43e | 422.5a | 5.81ab |

| CV(%) | 6.39 | 4.73 | 4.76 | 2.98 | 1.17 | 1.64 | 2.01 | 0.32 | 5.15 |

| LSD(%) | 0.48 | 0.20 | 0.23 | 0.25 | 1.51 | 0.87 | 2.04 | 2.21 | 0.49 |

Table 2: Interaction effect of taro varieties and blending ratio on proximate composition of composite breads.

NS = Non-Significance different at 5% probability level. Values with the same letters in the same column are not significantly different at 5% level of significance according to LSD test. Cont.= control (100g wheat flour bread, DB1, DB2 and DB3(Danu variety with 10,20 and 30g taro respectively), KB1, KB2 and KB3 (kiak variety with 10, 20 and 30g taro respectively, LB1, LB2L and B3 (Local variety with 10, 20 and 30g taro flour respectively) and C.V (coefficient of variance), LSD (list significant difference).

Sensory characteristics

Taste

The taste of the bread refers to the sweet sensation caused in the mouth by contact with the bread due to the sweetening agent. There was a significant difference (P < 0.05) in taste mean score of composite breads due to various blending ratios (Table 3). The Highest taste mean score was recorded in the 10g taro flour (4.88) statistically similar with control sample (4.77) and 20g taro flour (4.55) the least mean score was recorded in 30 g taro flour (4). Similar studies reported a decrease in the taste scores of wheat–taro flour composite bread with increased proportion of taro flour (Ammar., et al. 2009). This might be due to poor taro flour odor, after taste flavor, and also the high calcium oxalate contents of taro flour which contributes to the salty taste to the blended breads (Kaushal., et al. 2015). Mongi., et al. 2011 also studied that the 10% composite bread sample (CCB 1) had the highest mean score for taste.

Taste

The taste of the bread refers to the sweet sensation caused in the mouth by contact with the bread due to the sweetening agent. There was a significant difference (P < 0.05) in taste mean score of composite breads due to various blending ratios (Table 3). The Highest taste mean score was recorded in the 10g taro flour (4.88) statistically similar with control sample (4.77) and 20g taro flour (4.55) the least mean score was recorded in 30 g taro flour (4). Similar studies reported a decrease in the taste scores of wheat–taro flour composite bread with increased proportion of taro flour (Ammar., et al. 2009). This might be due to poor taro flour odor, after taste flavor, and also the high calcium oxalate contents of taro flour which contributes to the salty taste to the blended breads (Kaushal., et al. 2015). Mongi., et al. 2011 also studied that the 10% composite bread sample (CCB 1) had the highest mean score for taste.

There was a significant difference (P < 0.05) in taste content of composite breads due to various taro varieties (Table 3). The highest mean score for taste was recorded in the Danu variety (4.88) statistically similar with control sample (4.77) followed by kiak variety (4.33) and the least were for local variety (4.22). There was an interaction effect between blending ratios and taro varieties for taste content of composite bread samples (Table 4). the highest mean score for taste quality was recorded for kiak variety with 10g taro flour (5) statistically similar with dame variety with 20g taro flour (5), Danu variety with 30g taro flour (5), for local variety with 10g and 20g taro flour (5), kiak with 20g and local with 20g taro flour (4.33) and the least was recorded for local variety with 30g taro flour (3.33).

| Trts | Taste | Texture | Appearance | Color | Flavor | Overall acceptability |

| Main effects of blending ratio | ||||||

| B1 | 4.88a | 4.88a | 4.66ab | 4.88a | 4.44b | 4.77a |

| B2 | 4.55a | 4.33ab | 4.44b | 4.33b | 4.11b | 4.55a |

| B3 | 4b | 4b | 4.33c | 4.11b | 3.22c | 3.88b |

| Cont. | 4.77a | 4.55ab | 5a | 4.88a | 5a | 5a |

| Cv (%) | 10.48 | 12.37 | 9.73 | 10.46 | 9.13 | 8.66 |

| LSD (%) | 0.49 | 0.60 | 0.49 | 0.35 | 0.69 | 0.63 |

| Main effects of varieties | ||||||

| D | 4.88a | 4.66a | 4.55ab | 4.55a | 4.33b | 4.77ab |

| K | 4.33bc | 4b | 4.55ab | 4b | 3.66c | 4.33bc |

| L | 4.22c | 4.55ab | 4.33c | 4.77a | 3.77c | 4.11c |

| Cont. | 4.77ab | 4.55ab | 5a | 4.88a | 5a | 5a |

| Cv (%) | 11.29 | 14.10 | 10.98 | 8.11 | 9.35 | 11.65 |

| LSD (%) | 0.49 | 0.60 | 0.49 | 0.35 | 0.38 | 0.51 |

Table 3: Main effects of blending ratio and varieties on sensory qualities of taro –wheat composited breads.

NS = Non-Significance different at 5% probability level. Values with the same letters in the same column are not significantly different at 5% level of significance according to LSD test. Cont. = control (100g wheat flour bread, WB1 (100g wheat with 10g taro), WB2 (100g wheat with 20g taro) and WB3 (100g wheat with 30g taro) and C.V (coefficient of variance), LSD (list significant difference), WD (wheat with dame variety), WK (wheat with kiak variety), and WL (wheat with local variety)

Texture

Texture is the quality of the bread that can be decided by touch, the degree to which it is rough or smooth, hard or soft. (Rita, 2011). There was a significant difference (P < 0.05) in texture mean score of composite breads due to various blending ratios (Table 3). The highest mean score (4.88) was observed for10g taro which was statistically similar with 100g wheat bread (4.55) and 20g taro (4.33). The least score (4) was for the bread of the highest taro flour proportion (30g). This showed that, the level of supplementation influences the quality of dough thereby that of the texture of the bread. As the proportion of taro increased acceptability of bread texture reduced. The highest taro proportion resulted in a low score (4) that the texture was like moderately. This finding is in line with the work of Gizachew., et al. 2015.

Texture is the quality of the bread that can be decided by touch, the degree to which it is rough or smooth, hard or soft. (Rita, 2011). There was a significant difference (P < 0.05) in texture mean score of composite breads due to various blending ratios (Table 3). The highest mean score (4.88) was observed for10g taro which was statistically similar with 100g wheat bread (4.55) and 20g taro (4.33). The least score (4) was for the bread of the highest taro flour proportion (30g). This showed that, the level of supplementation influences the quality of dough thereby that of the texture of the bread. As the proportion of taro increased acceptability of bread texture reduced. The highest taro proportion resulted in a low score (4) that the texture was like moderately. This finding is in line with the work of Gizachew., et al. 2015.

There was a significant difference (P < 0.05) in texture mean score of composite breads due to various taro varieties (Table 3). The Highest texture mean score was recorded in the Danu variety (4.66) statistically similar with control sample (4.55 and local variety (4.55)) and the least was kiak variety (4).

There was an interaction effect between blending ratios and taro varieties for texture of composite bread samples (Table 4). The highest texture mean score quality was recorded for control sample (5) statistically similar with local varieties with 10g taro flour, Danu variety with 10g taro flour (5) and the least was recorded for kiak variety with 20g and 30g taro flour (3.66).

Appearance

Appearance is the surface characteristics of food materials which attracts the consumer perception. The appearance of taro–wheat bread was significantly (p < 0.05) affected by taro varieties, blending ratio and their interaction. The appearances mean score for most of the treatment groups were around moderately like. However, control exhibited the highest appearance score. This might be due to the low gluten protein contents of taro flour which contributes to make less leavened characteristics of blended breads (Emmanuel., et al. 2010),

Appearance is the surface characteristics of food materials which attracts the consumer perception. The appearance of taro–wheat bread was significantly (p < 0.05) affected by taro varieties, blending ratio and their interaction. The appearances mean score for most of the treatment groups were around moderately like. However, control exhibited the highest appearance score. This might be due to the low gluten protein contents of taro flour which contributes to make less leavened characteristics of blended breads (Emmanuel., et al. 2010),

There was a significant difference (P < 0.05) in appearance mean score of composite breads due to various blending ratios (Table 3). The Highest appearance mean score was recorded in the control sample (5) statistically similar with 10g taro flour (4.66) followed by 20g taro flour (4.44) and the least was recorded in 30g taro flour (4). This result was similar with the work of Gizachew., et al. 2016, The highest mean score (3.82) of appearance was recorded for 100g wheat flour bread followed by 3.52 for 11.12g, 3.51 for 25.00g and 2.92 for 42.90g cassava flours composite breads.

The highest mean score (3.82) of appearance was recorded for 100g wheat flour bread followed by 3.52 for 11.12g, 3.51 for 25.00 g and 2.92 for 42.90g cassava flours composite breads Gizachew., et al. 2016, there was a significant difference (P < 0.05) in appearance content of composite breads due to various taro varieties (Table 3). Highest appearance mean score was recorded in the control sample (5) statistically similar with Danu and kiak variety (4.55), (4.55) respectively and the least was recorded local variety (4.33) but still local variety is around moderately like.

There was an interaction effect between blending ratios and taro varieties for appearance content of composite bread samples (Table 4). The highest appearance mean score was recorded for control sample (5) statistically similar with Danu varieties with 10g taro flour (5) and the least was recorded for danu variety with 30g taro flour (4).

Color

The color of bread talks about the appearance of the bread, how It looks like, if it is appealing to the eyes, inviting and bright (Rita, 2011). The sensory mean scores for color are presented in Table 6. The blending ratio and taro variety and their interaction significantly (p < 0.05) affected the color of the composite bread. However, there was a general decreasing trend in the score with increase in proportion of taro flour beyond 20g. The highest score (4.88, extremely like) was observed for the control sample which is statistically similar with 10g taro flour (4.88) and the least was recorded for 30g taro flour (4.11 moderately like). This finding disagreed the finding of (Monji., et al. 2011) in which the significant increases in mean color scores for composite breads at increasing cocoyam substitution levels achieved. There was a significant difference (P < 0.05) in color content of composite breads due to various taro varieties (Table 3). The Highest color mean score was recorded in the control sample (4.88) statistically similar with local and Danu variety (4.77 and 4.55) respectively and the least was recorded kiak variety (4.33).

The color of bread talks about the appearance of the bread, how It looks like, if it is appealing to the eyes, inviting and bright (Rita, 2011). The sensory mean scores for color are presented in Table 6. The blending ratio and taro variety and their interaction significantly (p < 0.05) affected the color of the composite bread. However, there was a general decreasing trend in the score with increase in proportion of taro flour beyond 20g. The highest score (4.88, extremely like) was observed for the control sample which is statistically similar with 10g taro flour (4.88) and the least was recorded for 30g taro flour (4.11 moderately like). This finding disagreed the finding of (Monji., et al. 2011) in which the significant increases in mean color scores for composite breads at increasing cocoyam substitution levels achieved. There was a significant difference (P < 0.05) in color content of composite breads due to various taro varieties (Table 3). The Highest color mean score was recorded in the control sample (4.88) statistically similar with local and Danu variety (4.77 and 4.55) respectively and the least was recorded kiak variety (4.33).

There was an interaction effect between blending ratios and taro varieties for color of composite bread samples (Table 4). The highest color quality was recorded for control sample (5) statistically similar with danu varieties with 10g taro flour (5), local varieties with 10g (5) and 30g taro flour (5) and the least was recorded for kiak variety with 30g taro flour (3.33) which was neither like nor dislike .as a general it is considered as acceptable.

| Trts | Taste | Texture | Appearance | Color | Flavor | Overall acceptability |

| DB1 | 4.66a | 5a | 5a | 5a | 5a | 4.66ab |

| DB2 | 5a | 4.66ab | 4.66ab | 4.66ab | 4.66ab | 5a |

| DB3 | 5a | 4.33ab | 4b | 4c | 3.33cd | 4.66ab |

| KB1 | 5a | 4.66ab | 4.66ab | 4.66ab | 4.33ab | 4.66ab |

| KB2 | 4.33ab | 3.66b | 4.33ab | 4c | 3.33cd | 4.33ab |

| KB3 | 3.33cd | 3.66b | 4.66ab | 3.3d | 3.33cd | 4b |

| LB1 | 5a | 5a | 4.33ab | 5a | 4cd | 5a |

| LB2 | 4.33ab | 4.66ab | 4.33ab | 4.33cd | 4.33ab | 4.33ab |

| LB3 | 3.66c | 4ab | 4.33ab | 5a | 3d | 3c |

| Cont. | 4.66a | 5a | 5a | 5a | 5a | 5a |

| CV (%) | 11.56 | 14.03 | 11.42 | 8.18 | 9.73 | 12.13 |

| LSD (%) | 0.88 | 1.05 | 0.88 | 0.62 | 0.68 | 0.93 |

Table 4: Interaction effect of taro varieties and blending ratio on sensory qualities of composite breads.

NS = Non-Significance different at 5% probability level. Values with the same letters in the samecolumn are not significantly different at 5% level of significance according to LSD test. Cont. = control (100g wheat flour bread, DB1, DB2 and DB3 (Danu variety with 10,20 and 30g taro respectively), KB1, KB2 and KB3 (kiak variety with 10, 20 and 30g taro respectively, LB1, LB2L and B3 (Local variety with 10,20 and 30g taro flour respectively)and C.V (coefficient of variance), LSD (list significant difference).

Flavor

Flavor is a combination of aroma odor and taste. There was a significant difference (P < 0.05) in flavor mean score of composite breads due to various blending ratios (Table 3). highest flavor mean score was recorded in the control sample (5) followed by 10g and 20g taro flour (4.44) and (4.11) moderately like, respectively and the least was recorded in 30 g taro flour (3.22) which is neither like nor dislike. A decrease in odor and taste score of taro-wheat flour composite bread with increase in taro flour proportion has been reported in earlier studies (Ammar., et al. 2009) which are in agreement with the findings of this study. A decrease in the acceptability of the bread flavor was observed with an increase in the amount of cassava flour in the formulation Gizachew., et al. 2015)

Flavor is a combination of aroma odor and taste. There was a significant difference (P < 0.05) in flavor mean score of composite breads due to various blending ratios (Table 3). highest flavor mean score was recorded in the control sample (5) followed by 10g and 20g taro flour (4.44) and (4.11) moderately like, respectively and the least was recorded in 30 g taro flour (3.22) which is neither like nor dislike. A decrease in odor and taste score of taro-wheat flour composite bread with increase in taro flour proportion has been reported in earlier studies (Ammar., et al. 2009) which are in agreement with the findings of this study. A decrease in the acceptability of the bread flavor was observed with an increase in the amount of cassava flour in the formulation Gizachew., et al. 2015)

There was a significant difference (P < 0.05) in flavor mean score of composite breads due to various taro varieties (Table 3). the highest flavor mean score was recorded in the control sample (4.88) followed by dame variety (4.33) and the least was recorded kiak variety (3.66).

There was an interaction effect between blending ratios and taro varieties for flavor mean score of composite bread samples (Table 4). The highest flavor quality was recorded for control sample (5) statistically similar with dame varieties with 10g taro flour (5) and the least was recorded for local variety with 30g taro flour (3).

Overall acceptability

The overall acceptance expresses how the consumers or panelists accept the product generally. The overall acceptability scores of taro –wheat composite bread are presented in Table 6. Taro variety, blending ratio and their interaction significantly (p < 05) influenced the overall acceptability. The highest Overall acceptability was recorded in the control sample (5) statistically similar with 10g and 20g taro flour (4.77) and (4.55) moderately like respectively and the least was recorded for 30 g taro flour (3.88) neither like nor dislike. There was a general decreasing trend in the acceptability score with an increase in the proportion of taro flour beyond 20g of taro flour.

The overall acceptance expresses how the consumers or panelists accept the product generally. The overall acceptability scores of taro –wheat composite bread are presented in Table 6. Taro variety, blending ratio and their interaction significantly (p < 05) influenced the overall acceptability. The highest Overall acceptability was recorded in the control sample (5) statistically similar with 10g and 20g taro flour (4.77) and (4.55) moderately like respectively and the least was recorded for 30 g taro flour (3.88) neither like nor dislike. There was a general decreasing trend in the acceptability score with an increase in the proportion of taro flour beyond 20g of taro flour.

There was a significant difference (P < 0.05) in Overall acceptability mean score of composite breads due to various taro varieties (Table 3). Highest Overall acceptability mean score was recorded in the control sample (5) statistically similar with Danu variety (4.77) and the least was recorded local variety (4.11).

There were interactions effects between blending ratios and taro varieties for Overall acceptability mean score of composite bread samples (Table 4). The highest Overall acceptability quality was recorded for control sample (5) statistically similar with dame varieties with 10g taro flour (5), local 10g taro flour (5) and the least was recorded for local variety with 30g taro flour (3).

The study revealed that there is possibility of incorporating taro flour up to 20g per 100g of wheat with acceptable sensory attributes of the composite bread. In general, the taro varieties resulted in better score in the overall acceptability and other sensory attributes. This finding was not similar trend as reported by Ammar., et al. 2009).

The overall acceptability score of the bread with lowest proportion of taro flour containing breads was well above 4 (like moderately) in a scale of five suggesting that it is well above minimum acceptable score. Therefore, as with all other sensory parameters, supplementation of taro flour up to 20 g/100g wheat flour was observed to have no difference from wheat flour bread (control) with respect to overall acceptability. This result is in agreement with cookies of made from modified taro starch and cookies of made from taro flour Nip., et al. 1994.

Conclusion

Blending with Danu No 34, Kiak No 33 and local varieties had reduced moisture content to 4.42%, 3.85% and 3.78% respectively as compared to the moisture content (5.2%) in the control (100% wheat bread). Similarly, protein content dropped to 31.1%, 27.87%, 30.28% from 36.79%, crude fat content, 5.05%, 5.31% and 4.34% from 5.4% and energy 407.54 Kcal/100g, 410.07Kcal/100g and 405.73Kcal/100g from 421.63Kcal/100g, increased iron content 69.01,87,98 mg/kg and 97.92 mg/kg from 52.40 mg/kg, crude fiber content increased to 3.48%,2.32% and 3.31% from 2.67% and utilizable carbohydrate content increased to 62.59%, 63.74% and 62.73% from 52.30%. With increase in blending ratio the carbohydrate, the crude fiber and the ash contents increased whereas the protein content decreased significantly (P < 0.05).

As the blending ratio increased the overall acceptability dropped significantly (P < 0.05). It could be concluded that the substitution of taro flour with wheat flour in bread making with substitution level up to 20g did not adversely affect the quality properties of the bread and produce bread comparable to that produced from wheat flour in terms of proximate composition and sensory acceptability.

The implementation of this result will enhance food security and stimulate demand for taro flour as food industrial raw material and the addition of taro flour to wheat at a ratio of 20g: 100g produced acceptable bread and Incorporation of taro flour to wheat would therefore be an effective method of cost reduction of bread and other allied products in Ethiopia.

References

- Aboubakar., et al. “Physico-chemical, thermal properties and microstructure of six varieties of taro (Colocasia esculenta L.Schott) flours and starches”. Journal of Food Engineering 86.2 (2008): 294-305.

- Adane T., et al. “Effect of processing method on the roximate composition, mineral content and ant-nutritional factors of taro (colocasiaesculenta, l.) Grown in Ethiopia.” African Journal of Food, Agriculture, Nutrition and Development 13.2 (2013).

- Alcantara RM., et al. “The Nutritional Value and Phytochemical Components of Taro [Colocasiaesculenta (L.)Schott] Powder and its Selected Processed Foods”. Nutrition & Food Sciences 3 (2013): 207.

- Afaf O., et al. “Effect of substitution of wheat flour with taro flour on some properties of weaning food formula”. Journal of Applied science and research 9.6 (2013): 3985-3991.

- Alam F and A Hasnain. “Studies on and solubility of modified starch from taro (Colocasinesculenta) effect of pH and temperature”. Agriculturae Conspectus Scientificus 74.1 (2009): 45-50.

- Ammar MS., et al. “Using of Taro Flour as Partial Substitute of Wheat Flour in Bread Making.” World Journal of Dairy & Food Sciences 4.2 (2009): 94-99.

- Anon. Dry Kiln Operator’s Manual Handbook. Agriculture Handbook No-188. United State Departement of Agriculture (USDA) for Service Forest Production Laboratory, Madison, And Wood Industry. (2001).

- AryeeFNA., et al. “The physicochemical properties of flour samples from the roots of 31 varieties of cassava. Food Control 17 (2006): 916-922.

- Belderok B., et al. Bread making quality ofwheat. Springer, New York. (2000).

- Bradbury JH and RW Nixon. “The acridity of raphides from the edible aroids”. Journal of Food Science and Agriculture 76.4 (1998): 608–616.

- CSA (Centaral Stastical Authority) of Ethiopia. Statistical Report on Area and Production of Crops, Farm Management Practices, Farm Implements, Machineries and Storage Mechanisms. Addis Ababa Ethiopia. (2004).

- CSA, 2010/11.Crop Production Forcast Sample Survey. Ethiopia, Addis Ababa. Statistical Bulletin Number, 505.

- Emmans G C 2008: Free choice feeding of laying poultry. Pages 31-39 in Recent Advances in Animal Nutrition. W, Haresign and D.L.ewis, ed. Butterworths, London,Uk.

- EOSQ. Processedcerealbasedfoodforinfantandchildren.EgyptianOrganizationforStandardization and Quality, Ministry of Industry, Cairo. Egypt. (2005).

- Emmanuel-Ikpeme CA., et al. “Storage stability and sensory evaluation of taro chips fried in palm oil, palm olein oil, groundnut oil, soybean oil and their blends”. Pakistan Journal of Nutrition 6.6 (2007): 570-575.

- Ikpeme Emmanuel CA., et al. “Functional and sensory properties of wheat (Aestiumtriticium) and taro flour (Colocasiaesculenta) composite bread”. African Journal of Food Science 4 (2010): 248-253.

- Esayas Ayele. A thesis submitted to the school of graduate studies of Addis Ababa University in partial fulfillment of the requirement for the degree of Master of Science in food science and nutrition. (2009).

- FAO. Taro Cultivation in Asia and the Pacific, Food and Agriculture Organization of the United Nations (FAO), Rome, Italy. (1999).

- FAO. United Nations Food and Agriculture Organization. Roots, tubers, plantain andbananas inhuman Nutrition. (1990).

- FAO, 2008. Importance of Taro. Retrieved from; http: www.fao.org/docrep/005/AC450e. htm# Top of page, (access on: January 20, 2010).

- FAO/WHO. “Energy and Protein Requirement.” 52.118 Technical Report Series. Switzerland, Geneva. WHO (1973).

- Gizachew Girma., et al. “Effect of Cassava (Manihot Esculenta Crantz) variety, drying process and blending ratio on the proximate composition and sensory properties of Cassava- Wheat composite bread”. Direct Research Journal of Agriculture and Food Science (DRJAFS) 3.2 (2013): 38-47.

- Habtamu FG. Nutritional composition, antinutritional factors and effect of boiling on nutritional composition of Anchote (Cocciniaabyssinica) tubers. J SciInnov Res 3 (2014): 177-188.

- Haimanot H Ayele., et al. “Nutritional and sensory quality of wheat bread supplemented with cassava and soybean flours”. Journal Food Science & Technology 3.1 (2017): 1331892.

- Huang AS., et al. “Application of anion exchange high-performance liquid chromatography in determining oxalates in taro (Colocasiaesculenta (L.) Schott) corms”. Journal of Agriculture and Food Chemistry 40.11 (1992): 2123-2126.

- IFT. “Sensory evaluation guide for testing food and beverage products”. Sensory evaluation Div., Institute of Food technologists. Food Technology 35 (1981): 50-58.

- Jane J., et al. “Physical and chemical studies of taro starches and flours”. Cereal Chemistry 69 (1992): 528-535.

- Kochhar Sl. Economic Botany in the Tropics. MacMillan Indian Limitted. Delhi. (1998).

- Kwarteng JA and MJ Towler. West African Agriculture. A Textbook for Schools and Colleges. Macmillan Pub. London (1994): 128-129.

- Mongi RJ., et al. “Proximate composition, bread characteristics and sensory evaluation of cocoyam-wheat composite breads”. African Journal of Food, Agriculture, Nutrition and Development 11.7 (2011): 7.

- Nip WK. Taro root. pp. 355-387. In: D.S. Smith, J.N. Cash, W.K. Nip, Y.H. Hui, (eds). Taro: Processing Vegetable and Technology. Technomic Publishing, Pensylvania, USA. (1997).

- Njintang NY., et al. “Multivariate analysis of the effect of drying method and particle size of flour on the instrumental texture characteristics of paste made from two varieties of taro (Colocasia esculenta L. Schott) flour.” Journal of Food Engineering 81.1 (2007): 250-256.

- Sanful RS. Organoleptic and Nutritional Analysis of Taro and Wheat Flour Composite Bread: World Journal of Dairy & Food Sciences 6.2 (2011): 175-179.

- Siebel W. Future of Flours–Composite flours. (2011).

- Sim SY., et al. “Effects of selected food gums on wheat flour or dough properties”. The Journal of Agricultural & Food Industrial Organization 2 (2009): 937-947.

- Sramkova S., et al. “Chemical composition and nutritional quality of wheat grain”. Acta Chimica Slovaca 2.1 (2009): 115-138.

- Stauffer CE. Principles of dough formation. In: Technology of Breadmaking (eds S.P. Cauvain and L.S. Young), Blackie Academic&Professional, London. (1998): 262-295.

- Scott G., et al. “Roots and Tubers in the Global Food System - A vision statement for the year 2020”. (2000).

- Stone H and Sidel JL. Sensory evaluations practices, California: Academic Press. (1993).

- Soudy ID., et al. “Effects of traditional soaking on the nutritional profile of taro flour (Colocasiaesculenta L. Schott) produced in Chad”. Revue MédVét 1 (2010): 37-42.

- Standal BR., Nutritive value. In: J.K. Wan (eds). Taro: a review of Colocasiaesculenta (L.) Schott and its potentials. University of Hawaii Press, Honolulu. (1983): 141–147.

- Tsami E., et al. “Effect of method drying on sorption characteristics ofmodel fruit powders”. Journal of Food Engineering 38.4 (1999): 381-392.

- Vega-Mercado H., et al. “Advances in dehydration of foods”. Journal of Food Engineering 49.4 (2001): 271-289.

- Wieser H. The use of redox agents. In: Bread making: Improving Quality (ed. S.P. Cauvain), Woodhead Publishing, Cambridge (2003): 424-446.

Citation:

lamrot woldemariam. “Effects of Taro Varieties and Blending Ratios on Proximate Compositions, Sensory Qualities and Overall

Acceptability of Taro (Colocasia esculenta) –Wheat (Aestium triticium) Composite Bread”. Nutrition and Food Toxicology 2.6 (2018):

525-539.

Copyright: © 2018 lamrot woldemariam. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.