Research Article

Volume 3 Issue 5 - 2019

Physical and Sensory Characteristics of Composite Bread made from Chemically Peeled Cassava Cultivars’

1Department of Food Technology and Nutrition, Bells University of Technology Ota, Nigeria

2Department of Food Technology, University of Ibadan, Nigeria

2Department of Food Technology, University of Ibadan, Nigeria

*Corresponding Author: Arisa N.U, Department of Food Technology and Nutrition, Bells University of Technology Ota, Nigeria.

Received: March 27, 2019; Published: April 17, 2019

Abstract

Cassava roots have domestic and industrial importance in the tropical and subtropical countries. This study investigated the effect of chemical peeling on the physical and sensory characteristics of cassava composite bread. Roots from six cassava cultivars namely: TMS01/1371yr, TMS91/02324, TMS92/0326, TMS97/4763, TMS97/2205 and TMS30572 were immersed in 10% NaOH solution (1:2, w/v) at 96°C for 5 minutes; batches were either further immersed in 3% citric acid solution (1:2, w/v) at ambient conditions for 1 minute or immersed in 15% NaCl solution (1:2, w/v) at 96°C for 3 minutes. The softened peels of the pretreated cassava roots were washed off under running water with hard brushing. Another batch was peeled using a stainless steel knife. Peeled roots were processed into flour and flours were made into composite bread containing 10% cassava flour. Physical characteristics of bread loaves were evaluated using standard methods. Sensory attributes of loaves were determined using trained panelists. The loaf density of all wheat bread (0.13 g/mm3) was significantly lower than that of the composite bread (0.16-0.20g/mm3). There were no significant differences between the composite bread loaves and all wheat bread loaf in terms of crust colour, crumb colour, texture, flavour, aroma and eating quality (p < 0.05).

Keywords: Cassava roots; Chemical Peeling; Composite bread; Sensory and physical characteristics

Introduction

Cassava (Manihot escultenta Crantz) is cultivated in many tropical countries with sub-Saharan Africa being the leading producer of the crop (FAO, 1977; 1983; PRCIS, 2006; Sayre and Siritunga, 2003). Africa accounted for more than 90% of the global production of cassava in 2004, with Nigeria contributing about 38.4 million metric tonnes and coming up from the third position behind Brazil and Zaire in the Eighties to being the largest producer of cassava in the world today (Aro, 2008). Nigeria’s current production of cassava stands at about 45 million tonnes; followed by the Democratic Republic of Congo (DRC) 15 million tonnes, Angola and Ghana (about 12 million tonnes each) and Mozambique (9 million tonnes). Cassava is a staple food, contributing greatly to food security in Africa (UNCTAD, 2012; Ukwuru and Egbonu, 2013).

Cassava is a difficult crop to handle in the postharvest period. The high water content of between 60-70% makes the unprocessed roots bulky and difficult to handle (Khan et al., 2001). Roots start to deteriorate 1 to 3 days after they are harvested. Initial physiological deterioration is later compounded by microbial action (Cock, 1982). Under natural conditions, the roots show rather local and spotted deterioration symptoms (Kojima et al., 1983). Physiological deterioration, which occurs 2-3 days after harvest is caused by rapid post-harvest accumulation of certain phenolic compounds, especially scopoletin which in turn becomes complex in the presence of oxygen to form coloured blue black and brown pigments. This is usually initiated at site of mechanical damage and is related to tissue dehydration from wounds. Microbiological deterioration which is mostly caused by fungal infection results in changes in root phenolic metabolism and the appearance of coloured pigment around the infection site (Wheatley and Izquierdo, (1991); Khan et al., (2001)). Because of the high rates of deterioration of cassava roots after harvest, it is advantageous to process them quickly into shelf stable products. The processing of cassava into the different products involves a combination of operations which most often are common to all the products. They include peeling, washing, cutting, grating, fermentation, dewatering/drying, sieving and garification (Okaka, 2005).

The most fundamental of these operations is peeling in which the inedible outer parts of the roots consisting of the corky periderm and the cortex are removed. These are known to contain most of the cyanogenic glucosides (80%) present in the root (FAO, 1998). Most often peeling is done by hand using sharp knives; a slow and labour intensive operation (FAO, 1998).

The overarching strategy of the cassava transformation initiative in Nigeria is to turn the cassava sector into a major player in local and international starch, sweeteners, ethanol, high quality cassava flour (HQCF), and dried chips industries by adopting improved production and processing technologies and organizing producers and processors into efficient value-added chains (Ubah, 2014). About 10% of industrial demand of cassava is for production of HQCF used for the production of bread, biscuits and confectionery, dextrins, pre-gelled starch for adhesives, and starch and hydrolysates for pharmaceuticals and seasonings (Sanni., et al. 2007). The main factor that favoured the use of HQCF as wheat flour replacement in Nigeria was its lower cost compared with wheat flour. The price of HQCF was about 55 percent that of wheat flour delivered at bread bakeries (Abass., et al. 2011). This research therefore is aimed at evaluating the effect of chemical peeling on the quality characteristics and acceptability of composite bread made from cassava flour produced from chemically peeled cassava roots.

Materials and Methods

Six cassava cultivars namely TMS01/1371yr, TMS91/02324, TMS92/0326, TMS97/4763, TMS97/2205 and TMS30572 were used for the study. Freshly harvested roots from each cultivar were divided into three batches. The first and second batches were immersed in 10% NaOH solution (1:2, w/v) at 96°C for 5 minutes after which they were further treated. The first batch was further immersed in 3% citric acid solution (1:2, w/v) at ambient conditions for 1 minute, while the second batch was immersed in 15% NaCl solution (1:2, w/v) at 96°C for 3 minutes. The softened peels of the pretreated cassava roots were removed by hard brushing under running water. The third batch was manually peeled using stainless steel knives. Peeled roots were chipped and dried at 65°C. Dried chips were milled using Corona traditional corn mill REF 121 machine for a minimum of 6 milling stages to obtain a fine particle sized product, followed by sieving to obtain cassava flour (Figure 1).

Bread Making

The bread loaves were made using Flour mills of Nigeria PLC bakery procedure. Composites of the flour (10% cassava to 90% wheat flour (1000 g) were weighed into dry plastic bowls using an Avery Berkel weighing balance (model 122). Sugar (100 g), salt (15 g), fat (10 g), baking yeast (15 g) were also weighed using AND GF-400 weighing balance. The weighed out ingredients were poured into the mixing bowl of a Mc-Adam high-speed mixer and 500 mL of water was added and mixing was done for 15 minutes. The dough was cut into 500 g pieces, formed well and placed in well- greased (vegetable fat) baking pans followed by proofing for 2 hours 45 minutes in a Mc-Adam proofing chamber. Proofed dough was baked in a Mc-Adam baking oven at 195°C for 20 minutes. The baked bread loaves were placed on cooling tables to cool, packaged and stored away for analysis.

Bread Quality Characteristics Determination

Loaf volume, area, weight, density, height, width, depth and specific volume were determined at the Quality Control Laboratory of the Flour Mills of Nigeria PLC, Apapa, Lagos using text volume instruments BVM-L370 to which a PC HPL1710 was attached.

Loaf volume, area, weight, density, height, width, depth and specific volume were determined at the Quality Control Laboratory of the Flour Mills of Nigeria PLC, Apapa, Lagos using text volume instruments BVM-L370 to which a PC HPL1710 was attached.

Sensory Evaluation of the Bread

The acceptability of the composite bread loaves was determined using the method described by Land and Shepherd, (1984). A nine point hedonic scale questioniare was prepared to assess the loaf shape, crust color, texture, eating quality (mouth feel), flavor and aroma of the bread on the scale of like extremely [9], like very much [8], like moderately [7], like slightly [6], neither like nor dislike [5], dislike slightly (4), dislike moderately [3], dislike very much [2], dislike extremely [1]. Whole bread samples were separately arranged and coded 1 to 19.

The acceptability of the composite bread loaves was determined using the method described by Land and Shepherd, (1984). A nine point hedonic scale questioniare was prepared to assess the loaf shape, crust color, texture, eating quality (mouth feel), flavor and aroma of the bread on the scale of like extremely [9], like very much [8], like moderately [7], like slightly [6], neither like nor dislike [5], dislike slightly (4), dislike moderately [3], dislike very much [2], dislike extremely [1]. Whole bread samples were separately arranged and coded 1 to 19.

The bread samples [19] were cut into pieces and arranged in different white porcelain plates. Drinking Water (Eva) was also provided in white porcelain cups for mouth rinsing. Trained panelists [30] assessed and ranked the bread quality characteristics (both whole and pieces) on the basis listed above in a white painted well lit (flourescent light) laboratory.

Results and Discussions

The loaf volume of the bread loaves produced from substitutions of wheat flour with the different peeled cassava flours were significantly different from the loaf volume of bread made from 100% wheat flour (Table 1). Loaf volume of composite bread containing 10% cassava flour ranged from 2399 mm3 to 2832 mm3 and they were significantly lower than that of 100% wheat flour bread (3485 mm3). Analysis showed that neither peeling method nor cassava cultivar nor the interaction between the two factors had significant effects on loaf volume of bread containing cassava flour. The lower loaf volume of the composite bread may have been due to the reduction in the gluten content of the composite flours (10% cassava flour and 90% wheat flour). This would have led to reduction in elasticity and extensibility of the dough and is consistent with previous reports on the use of composite flour in bread-making (Olatunji & Akinrele, 1978; Esuoso and Bamiro, 1995; Oladunmoye., et al. 2010).

| CC | PM | LV | LW | LD1 | LA | LW | LSV | LD |

| (mm3) | (mm) | (mm) | (mm2) | (g) | (g/mm3) | |||

| TMS01/1371yr | Manual | 2615.8ab | 121.7ab | 142.1abcd | 1142.5abcd | 470.0de | 5.6abcde | 0.18bcdeffg |

| NaOH | 2511.7ab | 131.4ab | 140.8abc | 1160.9abcd | 471.5de | 5.3abc | 0.20g | |

| NaOH/NaCl | 2633.3ab | 148.3ab | 140.2abc | 1161.7abcd | 460.5bcd | 5.3ab | 0.19efg | |

| TMS92/0326 | Manual | 2698.7ab | 123.6ab | 147.3bcde | 1188.9bcd | 451.0ab | 6.1cdef | 0.17ab |

| NaOH | 2711.5ab | 139.4ab | 150.9cde | 1172.3abcd | 452.5abc | 6.0bcdef | 0.17abc | |

| NaOH/NaCl | 2832.3b | 137.4ab | 151.4cde | 1217.2d | 453.0abc | 6.3def | 0.16b | |

| TMS30572 | Manual | 2457.4ab | 142.9ab | 134.7ab | 1148.3abcd | 466.5de | 5.3ab | 0.19fg |

| NaOH | 2615.1ab | 142.7ab | 141.3abcd | 1146.2abcd | 462.0bcd | 6.6f | 0.18bcdef | |

| NaOH/NaCl | 2730.6ab | 148.3ab | 147.1bcde | 1195.1bcd | 444.0a | 6.1cdef | 0.16b | |

| TMS97/4763 | Manual | 2564.3ab | 138.7ab | 156.0ef | 1111.6ab | 465.0be | 5.6abcde | 0.19bcdefg |

| NaOH | 2585.1ab | 140.7ab | 147.5bcde | 1140.7abcd | 475.5e | 5.5abcd | 0.18bcdefg | |

| NaOH/NaCl | 2642.3ab | 124.8ab | 151.9cde | 1142.8abcd | 448.5de | 5.7abcde | 0.18bcdef | |

| TMS91/02324 | Manual | 2647.7ab | 138.1ab | 147.2bcde | 1154.9abcd | 448.5a | 5.9abcdef | 0.18bcdefg |

| NaOH | 2399.7a | 114.5a | 129.6a | 1095.7a | 462.5cd | 5.2a | 0.19fg | |

| NaOH/NaCl | 2810.1ab | 128.3ab | 155.2def | 1202.1cd | 461.0bcd | 6.1def | 0.17bc | |

| TMS97/2205 | Manual | 2555.1ab | 141.0ab | 153.7cdef | 1210.3d | 453.0abc | 6.3f | 0.16b |

| NaOH | 2526.7ab | 132.3ab | 141.8abcd | 1164.2abcd | 471.5de | 5.3abc | 0.19defg | |

| NaOH/NaCl | 2670.2ab | 149.5b | 133.5ab | 1152.8abcd | 462.5cd | 5.8abcde | 0.17bcdef | |

| Reference | wheatflour | 3485.8c | 154.5b | 166.1f | 1383.3e | 451.0ab | 7.8g | 0.13a |

Table 1: Effects of Peeling Method and Cassava Cultivar on Some Bread Quality Characteristics.

Means in a column with the same superscripts are not significantly different from one another (p < 0.05)

Legend

CC: Cassava Cultivar, PM: Peeling Method, LV: Loaf Volume, LD1: Loaf Depth, LA: Loaf Area, LW: Loaf Weight, LSV: Loaf Specific Volume, LD2: Loaf Density

CC: Cassava Cultivar, PM: Peeling Method, LV: Loaf Volume, LD1: Loaf Depth, LA: Loaf Area, LW: Loaf Weight, LSV: Loaf Specific Volume, LD2: Loaf Density

Bread width ranged from 121 mm for composite flour bread made from manually peeled TMS01/137/yr cassava variety to 154 mm for 100% wheat flour bread with no significant differences in breadth width between composite flour loaves and 100% wheat flour bread (Table 1). On the contrary, in general, bread depth was significantly greater for 100% wheat flour bread (166 mm) than for composite flour bread containing 10% cassava flour (129-151 mm) except for composite bread made from manually peeled TMS97/2205 (153 mm) and TMS97/4763 (156 mm) and NaOH/NaCl peeled TMS91/02324 (155 mm) cassava cultivars (Table 1). Loaf area was significantly greater for 100% wheat flour bread (1383 mm2) than for composite flour bread (1095-1217 mm2) with little differences between cassava varieties and peeling methods (Table 1). Loaf weight ranged from 444-475 g. In general, bread made from composite flour containing 10% cassava were comparable in loaf weight with 100% wheat flour bread that had a loaf weight of 451 g (Table 1). In contrast, 100% wheat flour bread was higher in specific volume (7.7) and was less dense (0.13) than composite flour bread with specific volume and density ranging from 5.20-6.64 and 0.16-0.20 respectively. The greater density of composite flour bread relative to 100% wheat flour bread may be significant for populations that prefer a denser bread that is more “filling to the stomach” when consumed and that staves hunger for a longer period of time.

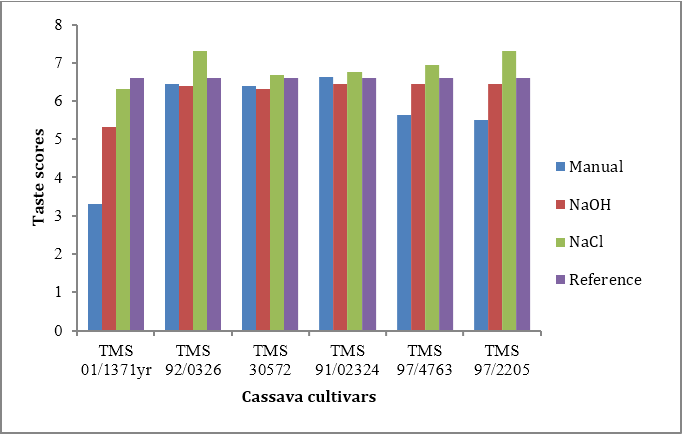

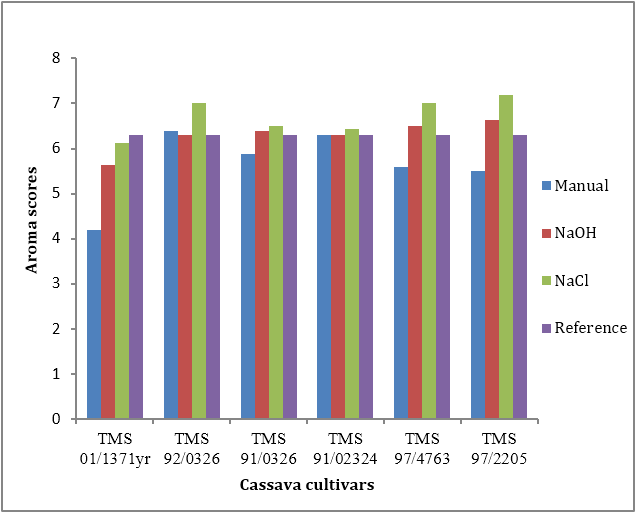

The sensory quality attributes of composite flour bread as influenced by cassava cultivars and peeling methods are presented in Figures 2 to 8. Composite flour bread containing 10% cassava flour from manually peeled TMS01/137yr received the least ratings for loaf shape (3.94; Figure 2), crust colour (4.63; Figure 3), taste (3.31; Figure 5) eating quality (4.81; Figure 6), flavour (3.94; Figure 7) and aroma (4.19; Figure 8). In general, bread made from composite flour containing 10% TMS92/0326, TMS30572, TMS91/02324, TMS97/4763 and TMS97/2205 cassava flour were highly rated for loaf shape (Figure 2), crust colour (Figure 3), crumb colour (Figure 4), taste (Figure 5), eating quality (Figure 6), flavour (Figure 7) and aroma (Figure 8) and were comparable to bread made from 100% wheat flour in these quality attributes irrespective of peeling method.

Figure 6: Effect of peeling method and cassava cultivar on eating quality of composite of composite bread

Conclusion

Bread produced from the composite flours of chemically peeled cassava compared favourably with all wheat bread. There were no significant differences between the composite bread loaves and all wheat bread loaf in terms of crust colour, crumb colour, texture, flavour, aroma and eating quality (p < 0.05).

Acknowledgements

Our appreciation goes to the members and staff of International Institute of Tropical Agricuture, Ibadan, Oyo State, Nigeria. Especially the staff of the Yam barn and Cassava programme; Dr Dixon, Mr Smith, Mr Adetoro, Mr Peter, Mr James Ogar, Mr Dayo, Mr Emeka for providing the cassava used. And National Root Crops Research Institute Umudike, Nigeria.

Our appreciation goes to the members and staff of International Institute of Tropical Agricuture, Ibadan, Oyo State, Nigeria. Especially the staff of the Yam barn and Cassava programme; Dr Dixon, Mr Smith, Mr Adetoro, Mr Peter, Mr James Ogar, Mr Dayo, Mr Emeka for providing the cassava used. And National Root Crops Research Institute Umudike, Nigeria.

We also thank the staff of Quality Control Department of Flour Mills of Nigeria PLC, Apapa, Lagos where the bread loaves were made and analyzed.

References

- Abass A B., et al. “Transitting cassava into an urban food and industrial commodity through agro-processimg and market driven approaches lessons”. Innovative policies and institutions to support agro-industries development C. A. Da Silva and N. Mhlanga eds. (2011): 305-352

- Agiriga AN and Iwe MO. “Physical properties of cookies produced from Cassava Groundnut corn starch Blend: A response surface Analysis”. Nigeria Food Journal 26.2: (2009): 83-96.

- Agiriga A N and Iwe M O. “Proximate composition of cookies produced from cassava groundnut corn starch blend”. Nigeria Food Journal (2009): 27.1 102-107.

- Agu H O., et al. “Quality characteristics of bread made from wheat and fluted pumpkin seed flour”. Nigeria Food Journal (2011): 28.1: 188-198.

- Aro SO. “Improvement in the nutritive quality of cassava and its by-products through microbial fermentation”. African Journal of Biotechnology 7.25 (2008): 789.

- Ayo JA., et al. “Effect of dough improves on the quality of acha (Digitaria exilis) flour bread”. Nigeria Food Journal26.1 (2008): 102-110.

- Chima CE and Gernah OI. “Physicochemical and sensory properties of cookies produced from cassava/soybean/mango composite flour”. Journal of Raw Material Research 4.1 (2007): 32-43.

- Cock J H. “Cassava: A basic energy source in the tropics”. Science, New Series, 218.4574 (1982): 755-762.

- Esuoso KO and Bamiro FO. “Studies on the baking properties of non-wheat flours-I. Breadfruit (Artocarpus altilis)”. International Journal of Food Sciences and Nutrition 46 (1995): 267-273.

- F.A.O. Cassava production and processing. Food and Agricultural Organization of the United Nations, Rome, Italy. (1977).

- F.A.O. Food loss prevention in perishable crops. Food and Agriculture Organization of the United Nations Rome, Italy. (1983).

- F.A.O. Processing of roots and tubers in the tropics. In: Srorage and Processing of Roots and Tuber.in the Tropics Food and Agriculture Organization of the United Nations,Rome,Italy. (1998).

- Gernah DI., et al. “Physicochemical and Sensory evaluation of cookies produced from wheat and brewers spent grain composite flour”. Nigeria Food Journal. 28.2 (2010): 440-447.

- Hanimex. What is Cassava? Hannimex Company. (2006).

- Ihediohanma NC. et al. “Functional properties and the performance of alum treated African bread fruit (Treculia africana) as composite flour in cake production”. Nigeria Food Journal 27.2 (2009): 159-167.

- Ihekoronye AI and Ngoddy PO. Food Science and Technology for the Tropics. Macmillan Publishing Ltd. London. (1985).

- Khan S., et al. “Evaluation of Caasava (Manihot esculenta Crantz) farine and wafer”. African Journal of Roots Tuber Crops 4.2 (2001): 39-41.

- Kojima M., et al. “Changes of Cyanide Content and Linamarase Activity in Wounded Cassava Roots.” Plant Physiology 72.1 (1983): 186-189.

- Land DG and Shepherd R. “Scaling and ranking methods”. Sensory Analysis ofFoods. J. R. Piggot Ed. Elsevier Applied Science Publishers, NewYork. (1984): 141-177.

- Ocheme O. et al. “Production and evaluation of bread using blend of unheated flour and fermented plantain flour”. Nigeria Food Journal28.2 (2010): 284-293.

- Okaka, JC. Processing of starchy roots, tubers and fruits. Handling, Storage and Processing of Plant Foods Academic publishers, Enugu. (2005): 237-255.

- Oladunmoye OO., et al. “Evaluation of some physical-chemical properties of wheat, cassava, maize and cowpea flours for bread making”. Journal of Food Quality 33 (2010): 693-708.

- Olatunji O and Akinrele IA. “Comparative rheological properties and bread qualities of wheat flour diluted with tropical tuber and breadfruit flours”. Cereal Chemistry 55 (1978): 1-6.

- Potter NN and Hotchkiss JA. Constituents of food properties and significance. Food Science 5th ed. CBS publishers, New Delhi: (2007): 24-45.

- P.R.C.I.S. Storing and Processing of Cassava. Phillipine Root Crops Information Service VISCA, Bayhoy. Leyte. (2006).

- Sanni L., et al. “Technology transfer in developing countries: Capitalizing on equipment development”. Journal of Food, Agriculture and Environment5.2 (2007): 88-91.

- Sayre R T and Siritunga D. “Researchers Get to the Roots of Cassava’s Cyanide Producing abilities”. Ohio State University Research Communications Columbus, Ohio. (2003).

- Uba, G. 2013. Investment in Cassava Farming and Processing Projects. This Day Live. August 8, 2014.

- UNCTAD. Cassava. Infocom commodity profile United Nations Conference on Trade and Development. (2012).

- Ukwuru MU and Egbonu SE. “Recent development in cassava-based products research”. Academia Journal of Food Research 1.1 (2013): 1-13.

- Wheatley C and Izouierdo. Case study: Fresh cassava storage. Integrated cassava projectworking document.C.A. Pereze Crespo ed. CIAT. Columbia 78 (1991): 62-92.

Citation:

Arisa N.U and Aworh O.C. “Physical and Sensory Characteristics of Composite Bread made from Chemically Peeled Cassava Cultivars’”. Nutrition and Food Toxicology 3.5 (2019): 731-740.

Copyright: © 2019 Arisa N.U. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.

Scientia Ricerca is licensed and content of this site is available under a Creative Commons Attribution 4.0 International License.